Edible protein, fat and polypeptide composition and self-assembling method thereof

A protein and polysaccharide technology, applied in food science, polysaccharide/gum-containing food ingredients, applications, etc., can solve problems such as adhesion to teeth and throat cavity, existence of small particles, sandy feeling, etc., to achieve easy absorption and reasonable distribution , easy to see through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

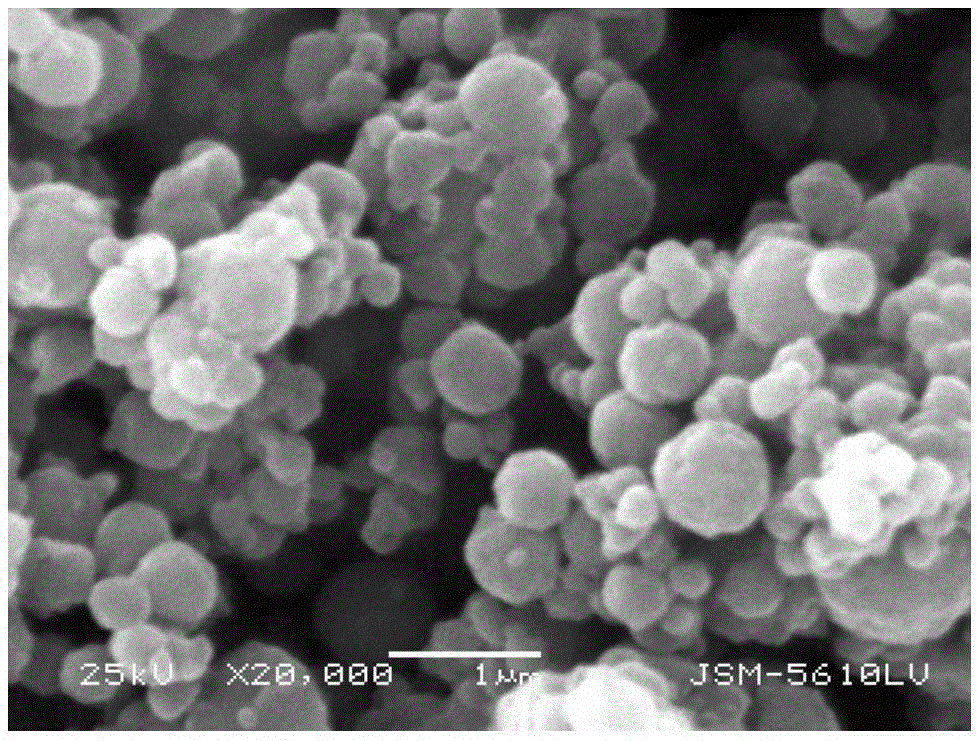

Image

Examples

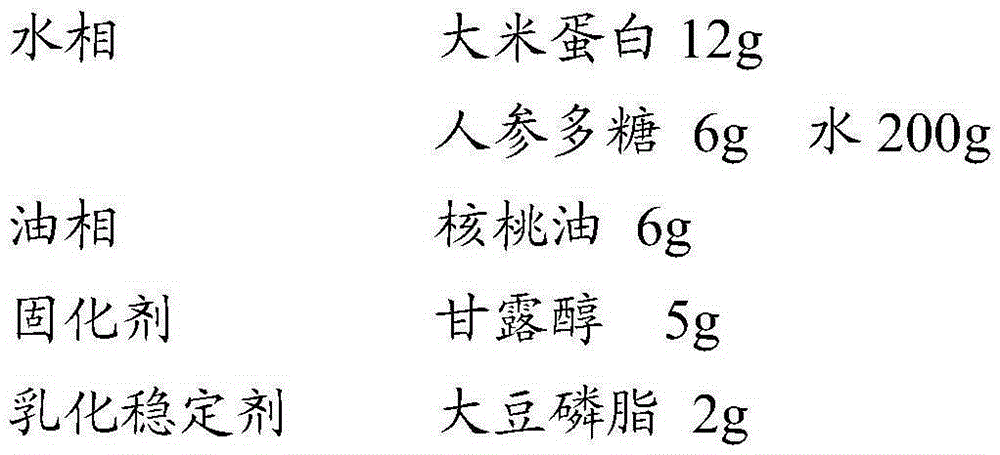

Embodiment 1

[0090]

[0091] Preparation method: Weigh rice protein and ginseng polysaccharide into water, stir and dissolve at 50°C as the water phase. Another weighed soybean lecithin was dissolved in walnut oil, heated at 60°C, stirred and dissolved as the oil phase. The oil phase was slowly added into the water phase and stirred for 10 min. After 1 minute of high shear, the homogenizer is 200 bar homogenized twice for self-assembly, and mannitol is added to the emulsion for spray drying. During spray drying, the temperature of the material is controlled at 80-90°C, and the inlet temperature is set at 110°C-120°C. ℃, the outlet temperature is 70℃-80℃, and the exhaust rate is 85%-90%.

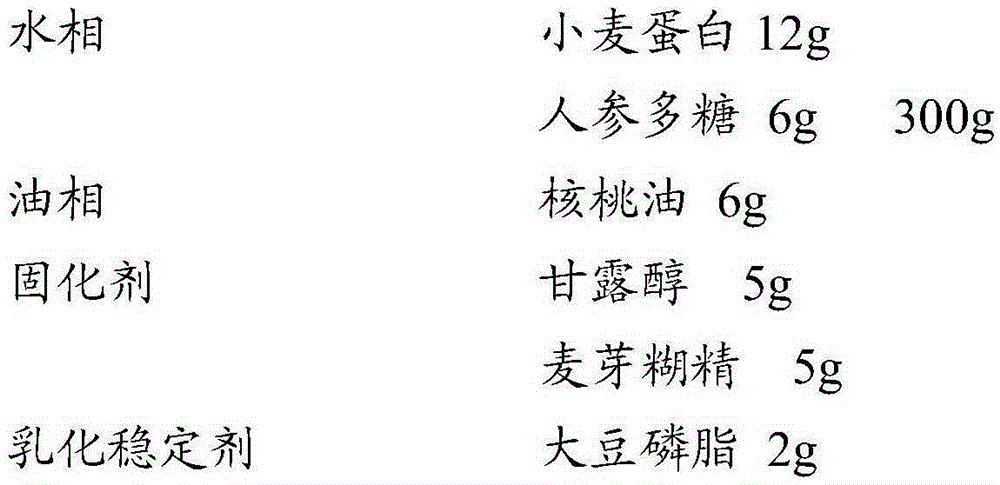

Embodiment 2

[0093]

[0094] Preparation method: Weigh rice protein and ginseng polysaccharide, add water, stir and dissolve at 30°C as the water phase. Another weighed soybean lecithin was dissolved in walnut oil, heated at 70°C, stirred and dissolved as the oil phase. The oil phase was slowly added into the water phase and stirred for 10 min. Then through high shear for 1min, 200bar homogenization by homogenizer for 2 times for self-assembly, adding mannitol and maltodextrin to the emulsion, and spray drying. Temperature 140°C-150°C, outlet temperature 80°C-90°C, exhaust rate 85%-90%).

Embodiment 3

[0096]

[0097]

[0098] Preparation method: Weigh rice protein, lentinan, maltodextrin, and mannitol, add to water, stir and dissolve to form the water phase. Another weighed soybean lecithin was dissolved in walnut oil, heated, stirred and dissolved as the oil phase. The oil phase was slowly added into the water phase and stirred for 10 min. Then carry out self-assembly through high shear for 2 minutes, and carry out spray drying. When spray drying, control the temperature of the material at 50°C-60°C (set the inlet temperature at 70°C-80°C, the outlet temperature at 50°C-60°C, and the ventilation rate at 85% -90%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com