Yoghourt and preparation method thereof

A technology of yogurt and milk protein powder, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of yogurt that need to be improved, and achieve the effect of low viscosity, strong stability, and strong drinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

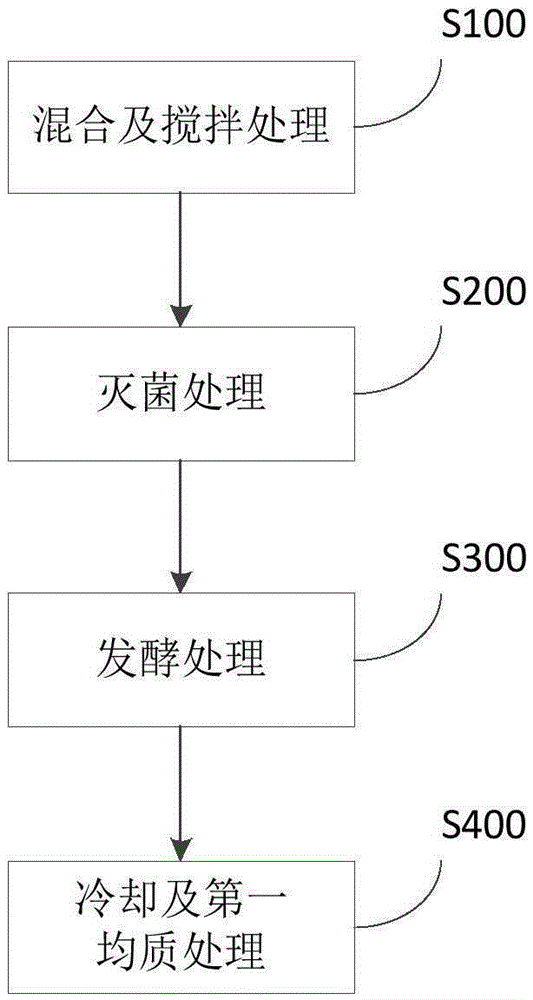

Method used

Image

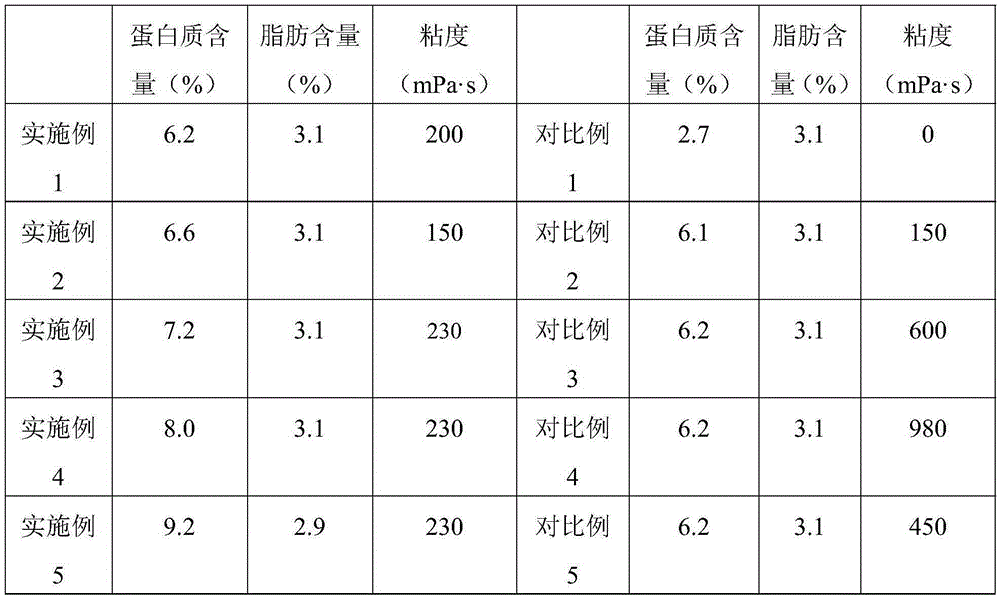

Examples

Embodiment 1

[0066] In this example, yogurt was prepared as follows:

[0067] The raw material composition of the yogurt includes: milk 875 parts by weight; white granulated sugar 70 parts by weight; milk protein powder MPC-60, 35 parts by weight; milk protein powder MPC-76, 18 parts by weight; whey protein powder WPC-52, 2 parts by weight .

[0068] The preparation process is as follows:

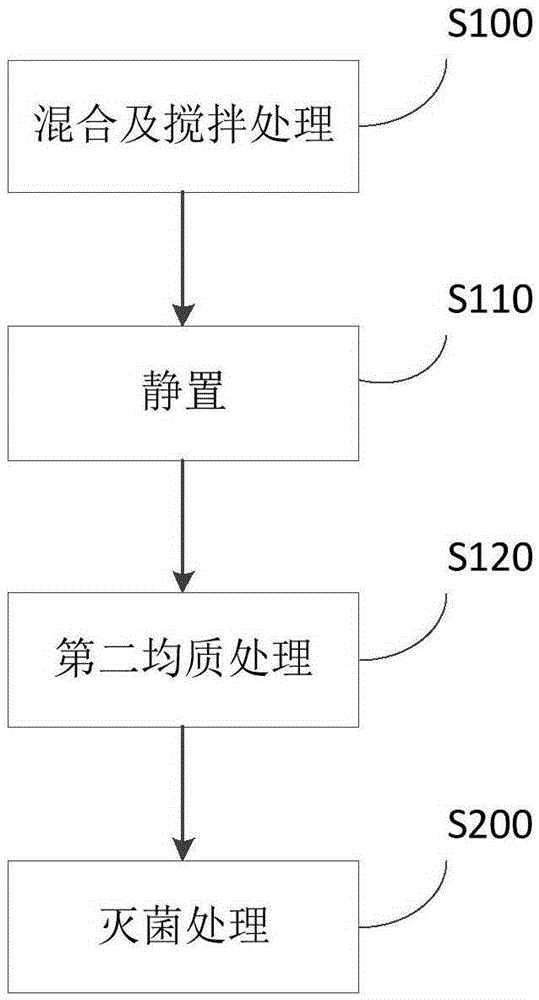

[0069] (1) Preheat the milk to 40°C, mix the sugar, milk protein powder and whey protein powder evenly, then slowly add to the milk, stir for 15 minutes, and stop stirring;

[0070] (2) Leave the mixture obtained in step (1) to stand for hydration for 30 minutes, then stir the hydrated feed liquid evenly, and perform homogenization at 65° C. under a pressure of 20 MPa;

[0071] (3) Sterilize the mixture obtained in step (2) at 95°C for 300s, and then cool the sterilized product to 37°C;

[0072] (4) Inoculate 0.01 parts by weight of commercially available starter (containing Streptococcus thermophilu...

Embodiment 2

[0076] In this example, yogurt was prepared as follows:

[0077] The raw material composition of the yogurt includes: milk 858.5 parts by weight; white granulated sugar 75 parts by weight; whey protein powder WPC-80, 1.5 parts by weight; whey protein powder WPC-42, 35 parts by weight; milk protein powder MPC-84, 30 parts by weight share.

[0078] The preparation process is as follows:

[0079] (1) Preheat the milk to 41°C, mix the sugar, milk protein powder and whey protein powder evenly, then slowly add to the milk, stir for 12 minutes, and stop stirring;

[0080] (2) Leave the mixture obtained in step (1) to stand for hydration for 60 minutes, then stir the hydrated feed liquid evenly, and perform homogenization at 95° C. under a pressure of 16 MPa;

[0081] (3) Sterilize the mixture obtained in step (2) at 95°C for 300s, and then cool the sterilized product to 43°C;

[0082] (4) Inoculate 0.01 parts by weight of commercially available starter (containing Streptococcus th...

Embodiment 3

[0086] In this example, yogurt was prepared as follows:

[0087] The raw material composition of the yogurt includes: milk 847 parts by weight; white granulated sugar 85 parts by weight; milk protein powder MPC-60, 45 parts by weight; milk protein powder MPC-84, 20 parts by weight; whey protein powder WPC-80, 3 parts by weight share.

[0088] The preparation process is as follows:

[0089] (1) Preheat the milk to 43°C, mix the sugar, milk protein powder and whey protein powder evenly, then slowly add to the milk, stir for 15 minutes, and stop stirring;

[0090] (2) Leave the mixture obtained in step (1) to stand for hydration for 45 minutes, then stir the hydrated feed liquid evenly, and perform homogenization at 75° C. under a pressure of 18 MPa;

[0091] (3) Sterilize the mixture obtained in step (2) at 95°C for 300s, and then cool the sterilized product to 42°C;

[0092] (4) Inoculate 0.25 parts by weight of commercially available starter (containing Streptococcus thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com