Solid cleaning agent composition

A technology of solid cleaning agent and composition, applied in the directions of detergent composition, surface active detergent composition, cleaning composition bleaching agent, etc. Keeps foaming, high cleaning power and strong degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

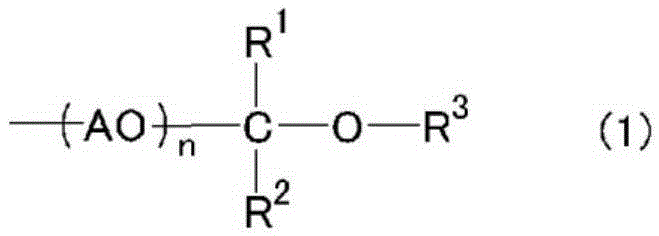

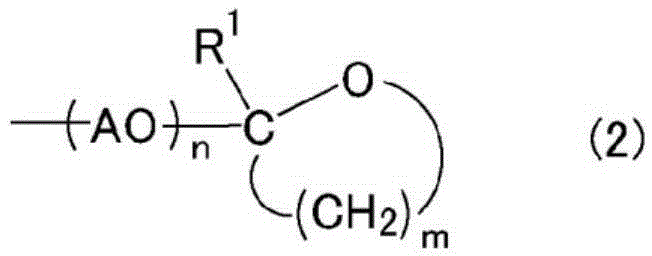

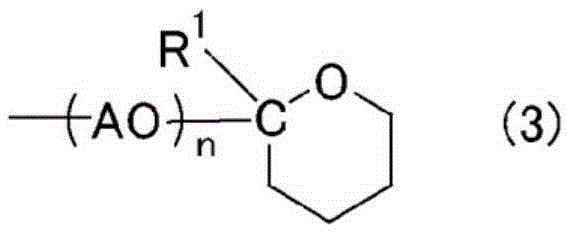

[0210] (Manufacture example 1) Manufacture of (A-1)

[0211] As a nonionic surfactant, there are 1 to 400 polyoxyalkylene alkyl ethers (manufactured by ADEKA Co., Ltd., ADEKANOLB722) (140 g) having oxyalkylene groups in the range of 1 to 400 and hydroxyl groups at the end of the alkylene oxide group. To the methyl chloride solution (50 ml), 20 g of dihydropyran (DHP) and 1 mol% p-toluenesulfonic acid as a catalyst were added, and stirred at room temperature overnight (10 hours). Sodium bicarbonate was added to complete the reaction, and after filtration, the solvent and unreacted dihydropyran were distilled off to obtain the target product.

[0212] The obtained product is the nonionic surfactant (A-1) which the terminal hydroxyl group of the said nonionic surfactant and DHP reacted, and which has an acetal structure at the terminal.

manufacture example 2

[0213] (Manufacture example 2) Manufacture of (A-2)

[0214] Polyoxyalkylene alkyl ether (manufactured by ADEKA Co., Ltd., ADEKANOLBO-922) (110 g) having 1 to 400 oxyalkylene groups as a nonionic surfactant and having a hydroxyl group at the end of the alkylene oxide group ) in dichloromethane solution (50 ml), add 18 g of ethyl vinyl ether and 1 mol% p-toluenesulfonic acid as a catalyst, and stir at room temperature overnight (10 hours). Sodium bicarbonate was added to complete the reaction, and after filtration, the solvent and unreacted ethyl vinyl ether were distilled off to obtain the target product.

[0215] The obtained product is the nonionic surfactant (A-2) which the terminal hydroxyl group of the said nonionic surfactant reacted with ethyl vinyl ether, and which has an acetal structure at the terminal.

manufacture example 3

[0216] (Manufacture example 3) Manufacture of (A-3)

[0217] Polyoxyalkylene alkyl ether (manufactured by ADEKA Co., Ltd., ADEKANOLB-2020) (300 g) having oxyalkylene groups within the range of 1 to 400 as a nonionic surfactant and having a hydroxyl group at the end of the alkylene oxide group ) in dichloromethane solution (50 ml), add 17 g of 2,3-dihydrofuran and 1 mol% p-toluenesulfonic acid as a catalyst, and stir at room temperature overnight (10 hours). Sodium bicarbonate was added to complete the reaction, and after filtration, the solvent and unreacted 2,3-dihydrofuran were distilled off to obtain the target product.

[0218] The obtained product is the nonionic surfactant (A-3) which the terminal hydroxyl group of the said nonionic surfactant reacted with 2, 3- dihydrofuran, and the terminal has an acetal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com