Herringbone tooth surface gear transmission mechanism and tooth milling method for herringbone tooth surface gear of herringbone tooth surface gear transmission mechanism

A transmission mechanism, herringbone tooth technology, applied in the direction of gear transmission, transmission, components with teeth, etc., can solve the problems such as the inability to effectively utilize the tooth width to carry, the carrying capacity is not high, the degree of coincidence is small, etc. The effect of popularization, large carrying capacity and increased carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

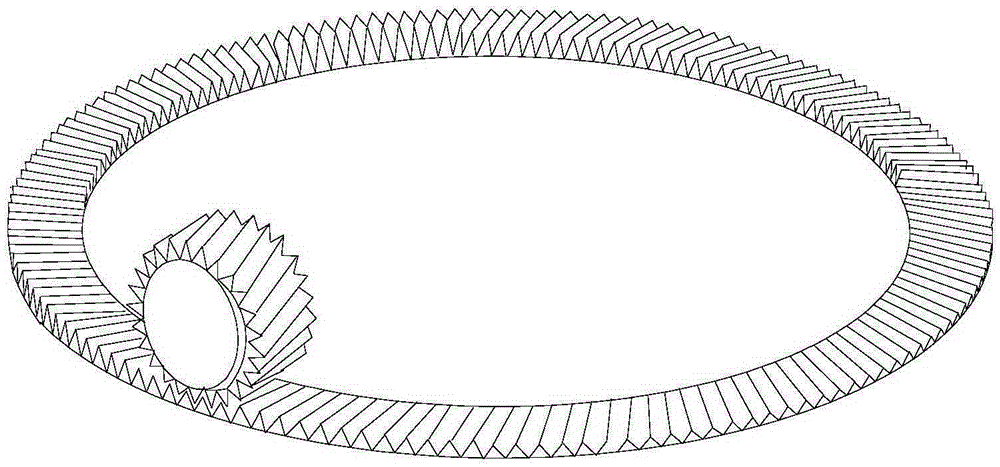

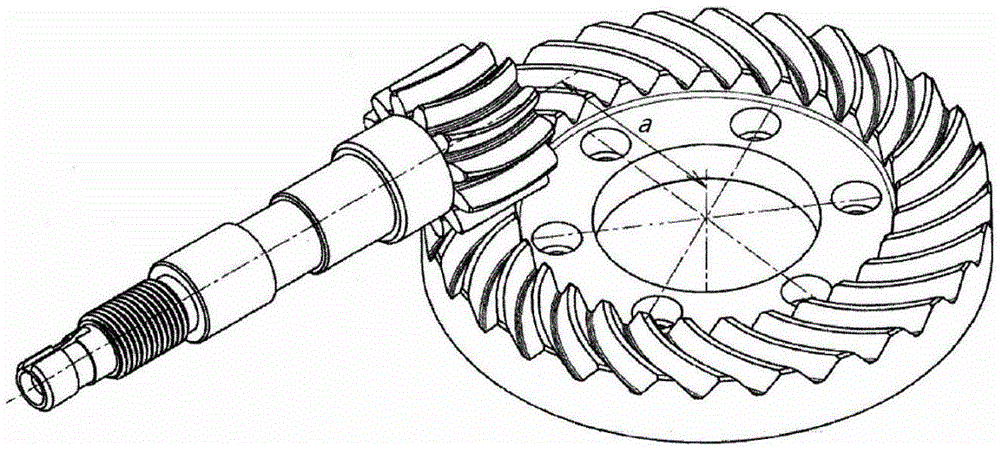

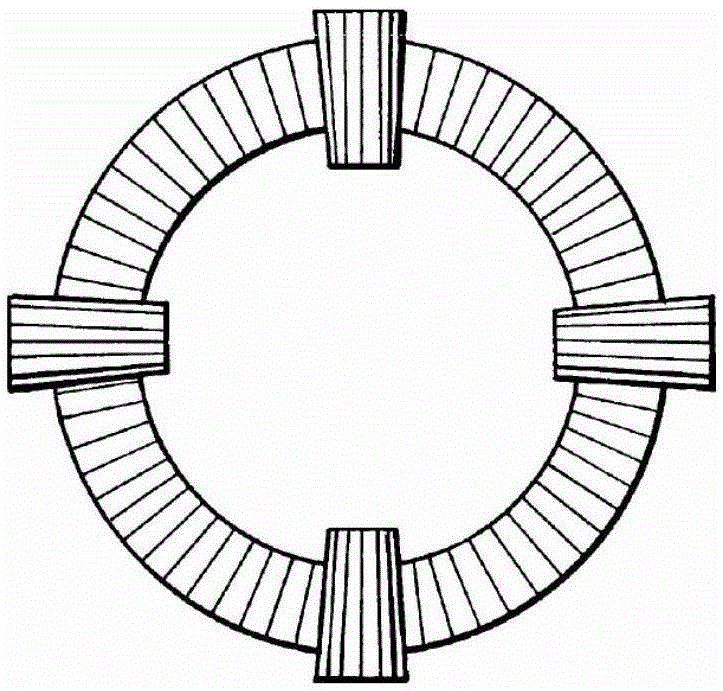

[0044] Such as Figure 4 , Figure 5 and Figure 6 As shown, the herringbone gear transmission mechanism of the present invention includes a herringbone gear 1 and a herringbone cylindrical gear 2 whose axes are perpendicular to each other and meshed with each other. The said herringbone gear 1 includes a disc-shaped wheel Body 9 and the gear shaft 10 located in the middle of the disc-shaped wheel body 9, one side surface of the disc-shaped wheel body 9 is provided with the first herringbone teeth in the ring with the center of the gear shaft 10 as the center of the circle 3. The second herringbone tooth 4 is arranged on the outer circumference of the wheel of the herringbone cylindrical gear 2, and the first herringbone tooth 3 is composed of the first right-handed gear tooth 7 and the first left-handed gear tooth in a herringbone shape. The second herringbone tooth 4 is composed of the second left-handed gear tooth 5 and the second right-handed gear tooth 6 that are docked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com