A kind of preparation method of compound antibacterial soap

A kind of antibacterial soap and compound technology, which is applied in the direction of chemical instruments and methods, skin care preparations, soap detergent compositions, etc., can solve the problems that are unfavorable to the sustainable and healthy development of the deep processing industry, so as to enrich the categories and shorten the reaction time , Excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

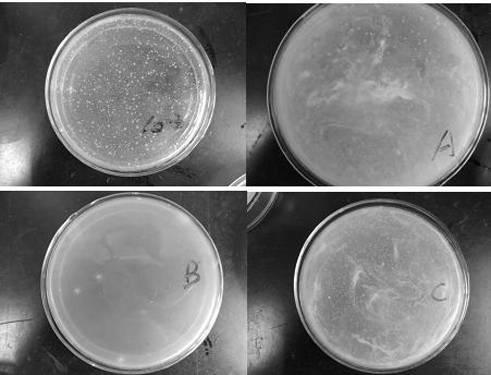

Image

Examples

Embodiment 1

[0030] Weigh 40g coconut oil, 30g palm oil, 20g olive oil, 10g tea seed oil, 20g sweet almond oil, 10g grapeseed oil, mix them, homogenize through a homogenizer, and place them in a water bath at 40°C to keep warm. Add 56g of ice cubes to 20g of sodium hydroxide and dissolve it. Keep the temperature at about 40°C. Add the sodium hydroxide solution and 1g of tea protein emulsifier to the mixed oil and stir for reaction for 3 hours. When the temperature drops to 20°C, add the Soak 1.0g of tea extract in 10 DEG C of olive oil and tea seed oil for 24h (wherein the mass ratio of tea polyphenols and tea saponin is 1:10), then add a mass concentration of 10% sodium chloride solution, drain Take out part of the glycerin, continue stirring evenly, and put it into the mold. The soap is solidified and demoulded in 2 days, and slowly matured in a dark and ventilated place for 50 days to form a compound antibacterial soap 1.

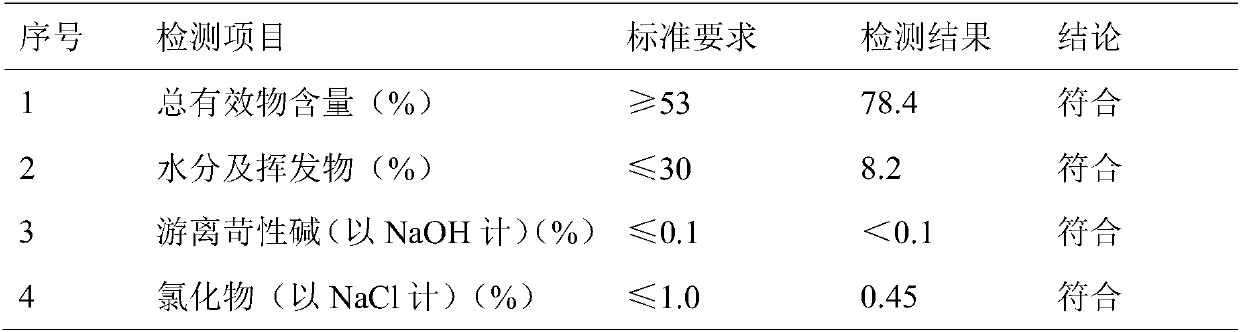

[0031] The test results show that the total active substance co...

Embodiment 2

[0037] Weigh 20g coconut oil, 10g palm oil, 5g olive oil, 15g tea seed oil, 10g sweet almond oil, 5g grapeseed oil, mix them, homogenize through a homogenizer, and place them in a water bath at 40°C to keep warm. Add 40g of ice cubes to 15g of sodium hydroxide and dissolve it. Keep the temperature at about 40°C. Add the sodium hydroxide solution and 2.5g of tea protein emulsifier into the mixed oil and stir in turn. After reacting for 2 hours, wait until the temperature drops to 25°C and add 0.60g of tea extract (wherein the mass ratio of tea polyphenols and tea saponin is 1:15) soaked in tea seed oil at 20°C for 20h, then add a sodium chloride solution with a mass concentration of 8%, and drain part of the glycerin , continue to stir evenly and put it into the mold, the soap will be solidified for 2 days to release the mold, and mature in a dark and ventilated place for 40 days to form a compound antibacterial soap 2.

[0038] The test results show that the total active subst...

Embodiment 3

[0040]Take by weighing 45g coconut oil, 20g palm oil, 15g olive oil, 5g tea seed oil, 15g sweet almond oil, 15g grapeseed oil and mix it, then pass through a homogenizer to homogenize it, and place it in a water bath at 40°C to keep warm. Add 54g of ice cubes to 19g of sodium hydroxide and dissolve it. When the temperature is 35°C, slowly add it to the mixed oil, then add 1.5g of tea protein emulsifier and keep stirring. To 25 ℃, 0.90 g of tea extract (wherein the mass ratio of tea polyphenols and tea saponin is 1:20) that has been soaked in 30 ℃ olive oil and tea seed oil for 15 hours, was added with a mass concentration of 10% chlorine Sodium chloride solution, drain part of the glycerin, continue to stir evenly, and put it into the mold. The soap is solidified and demoulded in 2 days, and matured in a dark and ventilated place for 50 days to form a compound antibacterial soap 3.

[0041] The test results show that the total active substance content in the compound antibacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com