A 3D printing feeding mechanism and its application method

A feeding mechanism and 3D printing technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to meet industrial printing needs, low conveying efficiency, and large installation space, so as to save installation space and reduce cost, the effect of increasing the delivery volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

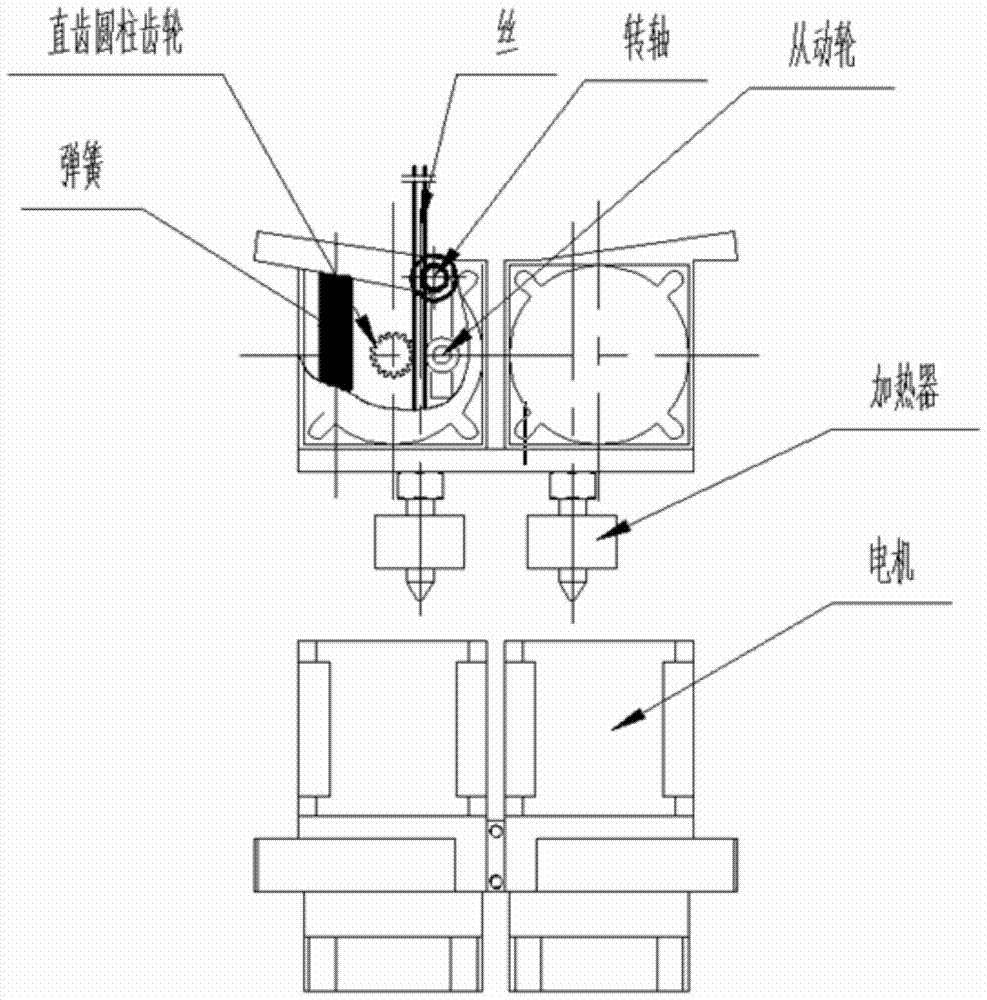

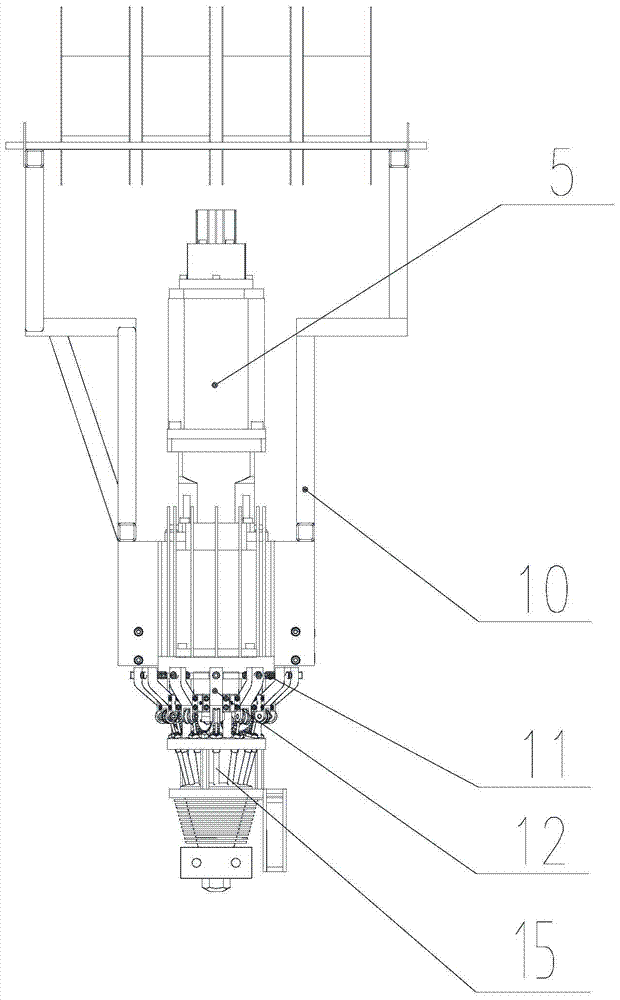

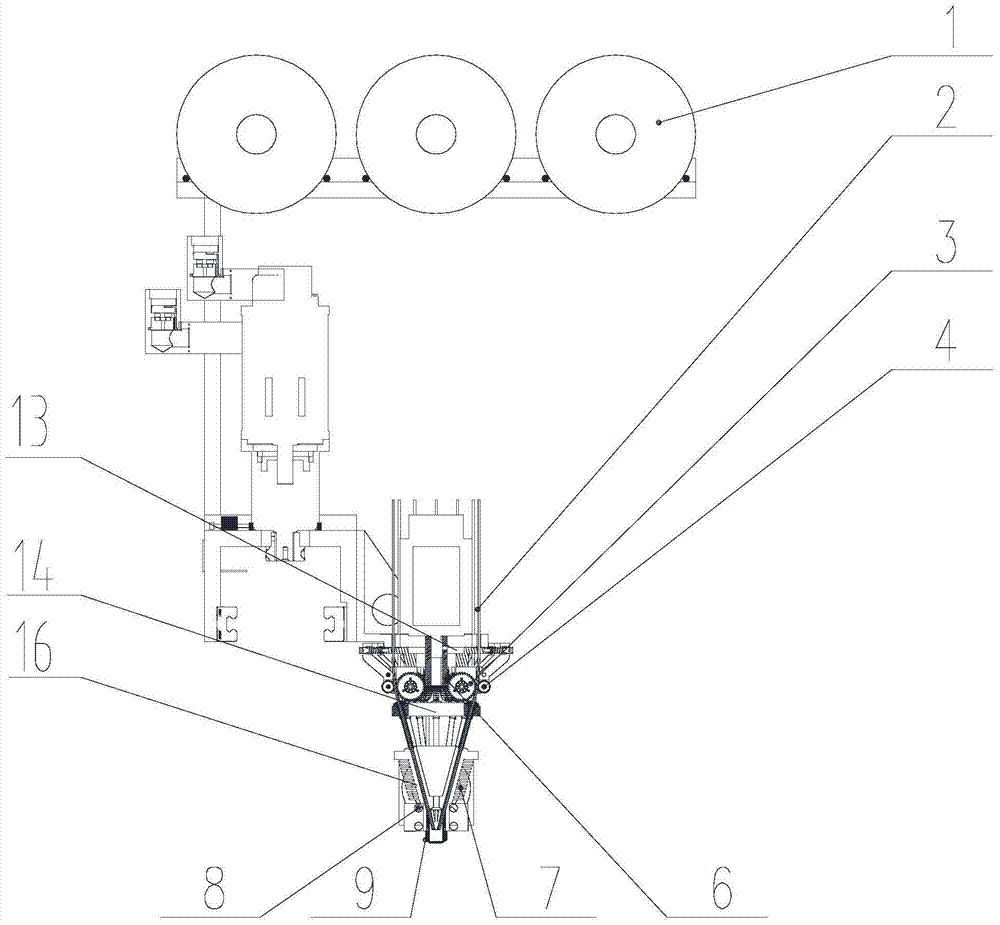

[0019] structured as figure 1 and figure 2 As shown, a 3D printing feeding mechanism provided in this embodiment includes a horizontally arranged bracket fixing platform 13, the bracket fixing platform 13 is in the shape of a disk, and a turbine installation platform 14 is sequentially arranged below it along the vertical direction from top to bottom. , radiator 7, heater 8 and nozzle 9, turbine installation platform 14 is parallel to support fixed platform 13, and the vertical axis of support fixed platform 13, turbine installation platform 14, radiator 7, heater 8 and nozzle 9 is mutual coincide and the horizontal cross-sectional area decreases successively;

[0020] It also includes a vertically arranged worm 6 and the worm 6 passes down the central position of the bracket fixing platform 13 to the turbine installation platform 14, and the turbine installation platform 14 is provided with a plurality of identical turbines 3, and the turbine 3 is a vertical side and are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com