Preparation method for nickel cobalt lithium aluminate small-particle single-crystal material

A technology of nickel-cobalt-lithium aluminate and nickel-cobalt-aluminum, which is applied in the field of positive electrode materials for high specific capacity lithium-ion batteries and its preparation, can solve problems restricting the application of NCA materials, achieve improved cycle stability, uniform particles, and reduce surface alkaline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

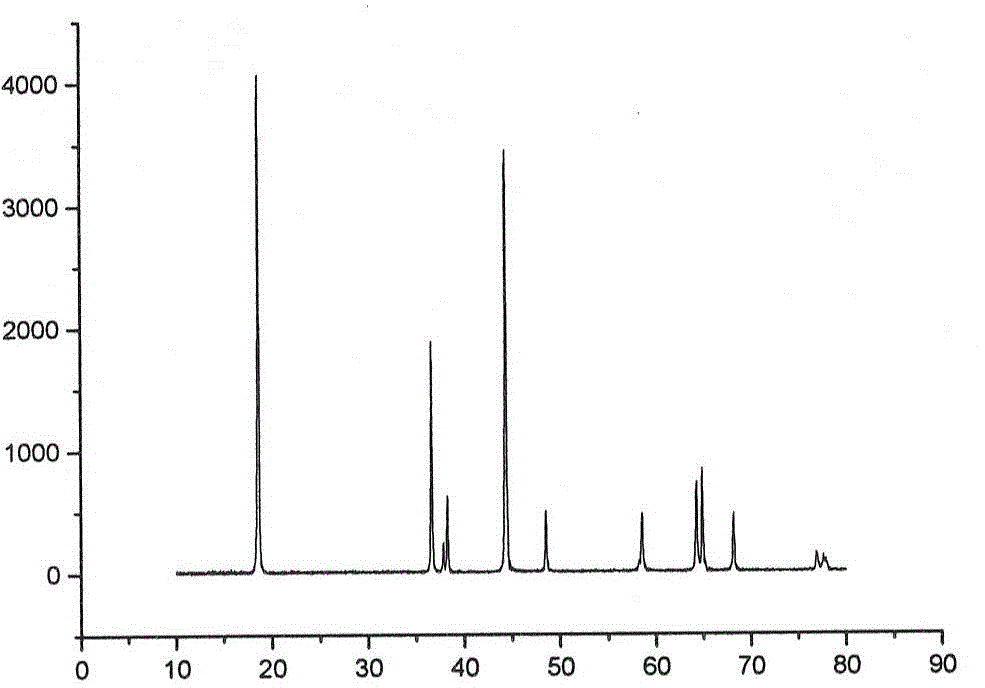

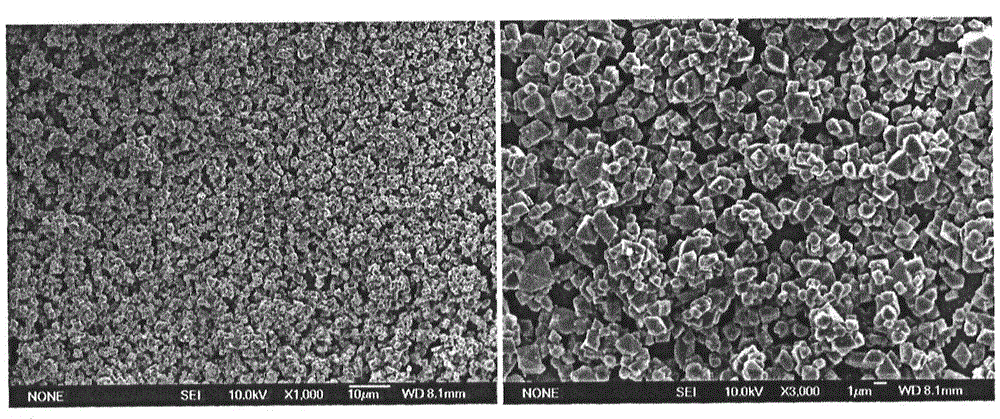

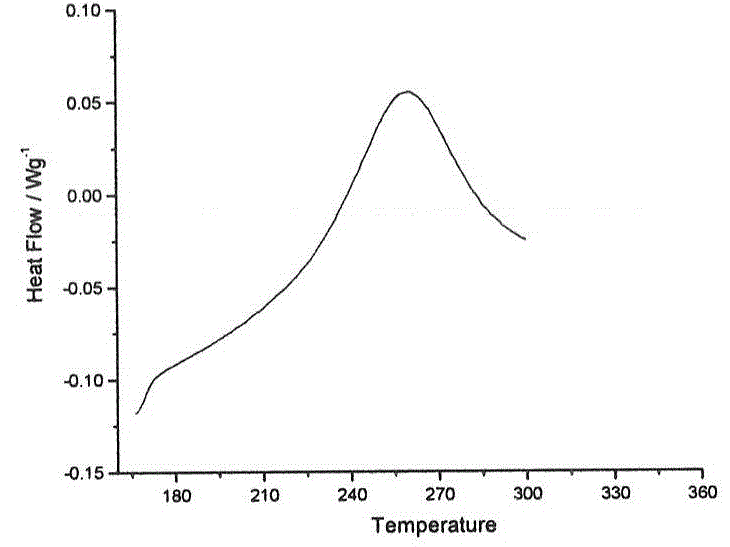

Image

Examples

Embodiment 1

[0019] Example 1: Dissolve nickel salt, cobalt salt, and aluminum salt in deionized water and mix evenly to obtain a 2M nickel-cobalt-aluminum salt solution, wherein the molar ratio of nickel-cobalt-aluminum ions is: 8:1.5:0.5, and will contain 8M The 12M sodium hydroxide solution of ammonia water is used as the alkaline solution and the nickel-cobalt-aluminum solution and flowed into the high-speed stirring reactor. Injecting liquid, separating the obtained slurry into solid and liquid, washing the obtained solid material and drying in an oven at 120°C for 8 hours to obtain a nickel-cobalt-aluminum precursor. Mix the nickel-cobalt-aluminum precursor and the lithium source at a molar ratio of 1:1.05, put them into a roaster, roast them at 300°C for 8 hours in an air atmosphere, and then lower them to room temperature. Pass the roasted materials through a 500-mesh sieve. The sieved material, polyethylene glycol accounting for 8% of the mass of the material and 300ml of pure wat...

Embodiment 2

[0022] Dissolve nickel salt, cobalt salt, and aluminum salt in deionized water and mix evenly to obtain a 2M nickel-cobalt-aluminum salt solution, wherein the molar ratio of nickel-cobalt-aluminum ions is: 8:1:1. Sodium hydroxide solution is used as alkaline solution and nickel-cobalt-aluminum solution and flow into the high-speed stirring reactor, adjust the flow rate of the alkaline solution to control the pH value in the reactor between 11.5-12.5, stop the injection after the injection of the nickel-cobalt-aluminum solution, and put The obtained slurry is subjected to solid-liquid separation, and the obtained solid material is washed and dried in an oven at 150 degrees for 8 hours to obtain a nickel-cobalt-aluminum precursor. Mix the nickel-cobalt-aluminum precursor and the lithium source in a molar ratio of 1:1.1, put them into a roaster, roast them at 500°C for 20 hours in an air atmosphere, then lower them to room temperature, and pass the roasted materials through a 500-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com