Backside laser membrane opening method and system of back passivation solar cell

A solar cell and back passivation technology, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as adhesion, achieve the effects of improving failure ratio, simplifying back passivation process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

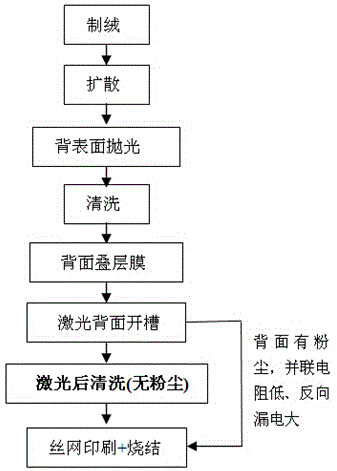

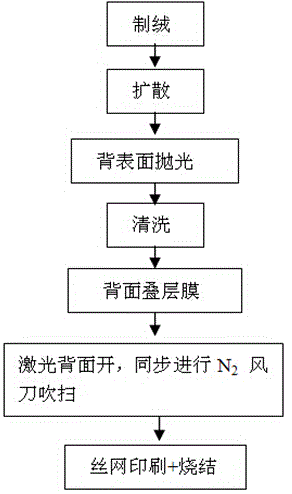

[0022] The structure of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. In the present invention, the same parts as the prior art will refer to the prior art.

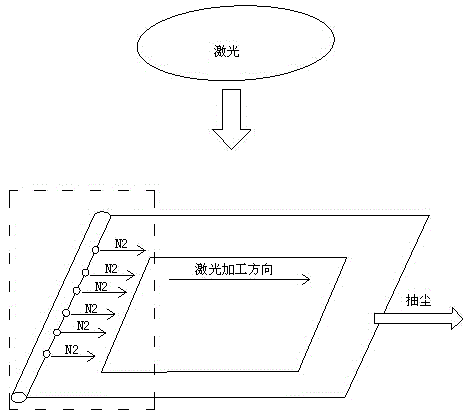

[0023] Such as figure 2 As shown, the back surface laser opening method of the back passivation solar cell of the present invention includes a laser slotting process and a dust removal process, and the dust removal process is performed synchronously with the laser slotting process. 2 Air purging process, N 2 The gas is pressurized gas, and its pressure range is 0.4-0.8Mpa. In this embodiment, the pressure is controlled at about 0.6Mpa; N 2 The gas outlet is located at the starting point of the laser groove. It also includes a dust extraction process synchronized with the dust removal process.

[0024] Increase N 2 After the gas purging process, the attached dust on the back surface of the silicon wafer can be completely removed. The back s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com