Continuously variable transmission device

A technology of infinitely variable transmission and axle wheel, applied in the direction of transmission, friction transmission, belt/chain/gear, etc., can solve the problems of glue damage, inability to work, vibration, etc., to prevent transmission failure and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

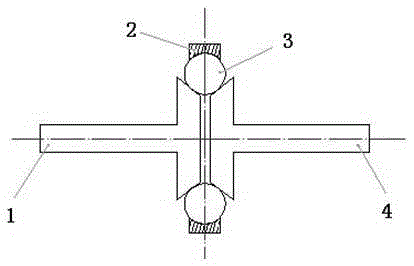

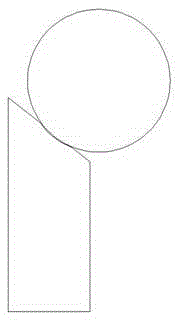

[0015] refer to figure 1 , 2 , the present embodiment provides the main structure of a new continuously variable transmission device, including a power input shaft 1 , an automatic pressurization device 2 , a set of steel balls 3 , and a power output shaft 4 .

[0016] The shaft wheel of the power input shaft 1 is connected with the shaft wheel of the power output shaft 4 through a group of steel balls 3, and an automatic pressurizing device 2 is installed on the group of steel balls 3.

[0017] Depend on figure 1 It can be seen that the power is input by the shaft 1 to drive the driving wheel to rotate, and the power output shaft 4 is driven to rotate through the automatic pressurizing device 2 and a group of steel balls 3 . The steel ball 3 can change the angle and position to adjust the output speed and torque of the driven wheel of the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com