Blowing type roller washing machine and clothes-washing method thereof

A drum washing machine, gas type technology, applied in the field of washing machines, can solve problems such as raising the water level of washing liquid, and achieve the effects of speeding up dissolution, saving electric energy and energy consumption, and improving the washing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

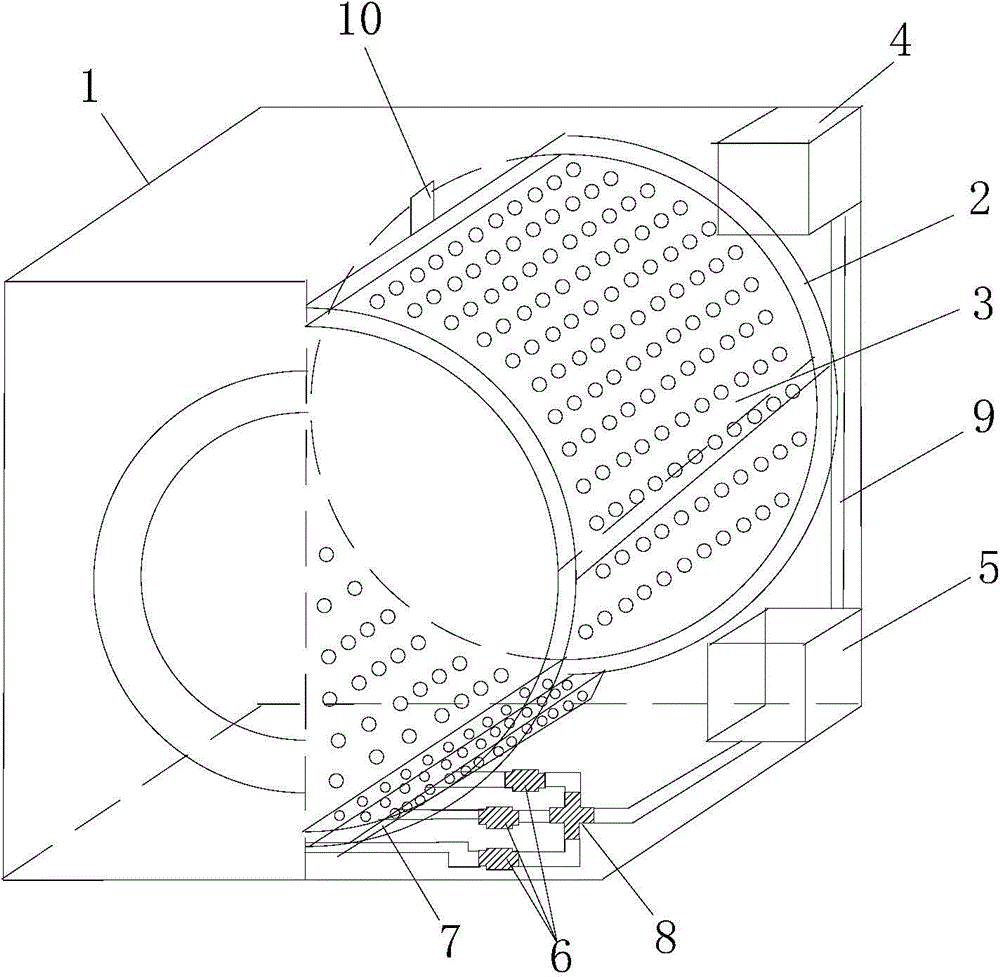

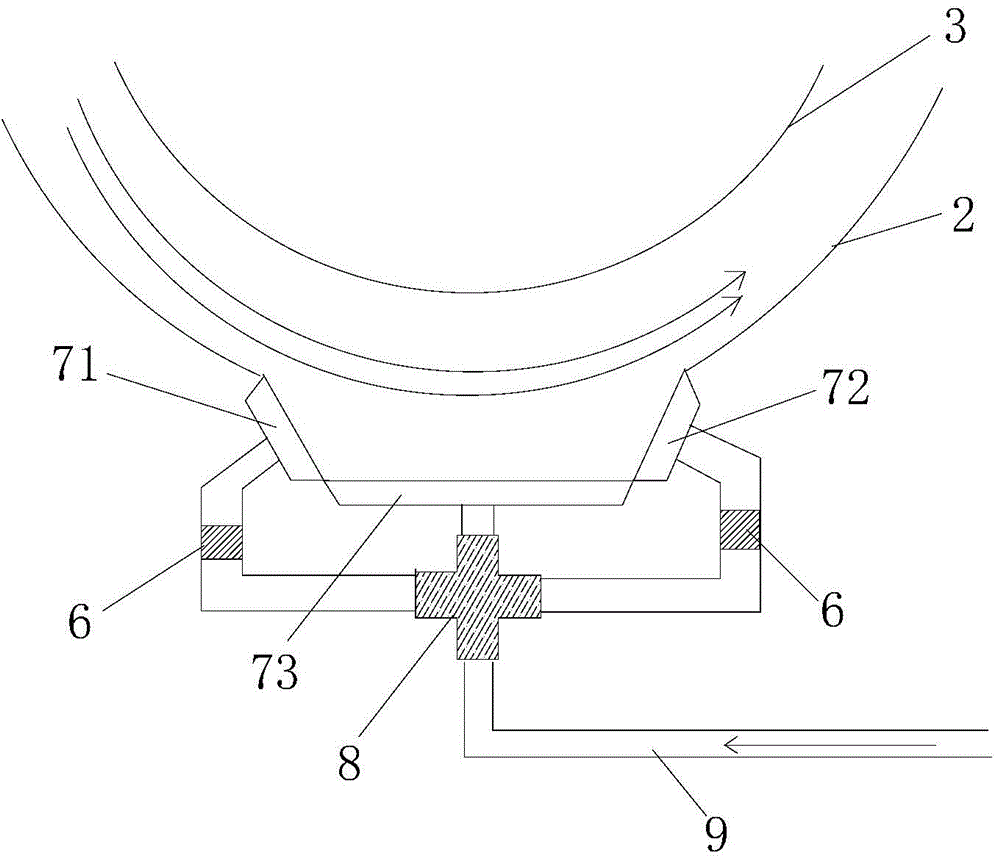

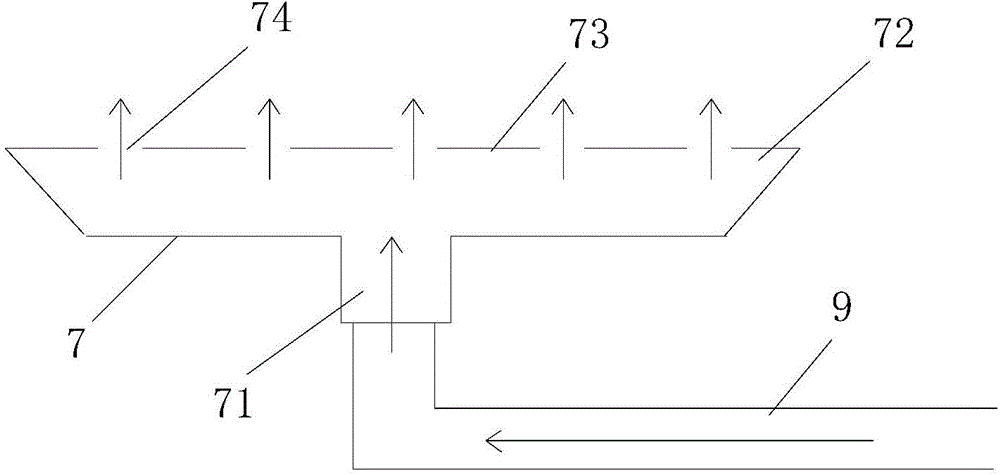

[0037] Such as figure 1 and Figure 5 As shown, the drum washing machine of the present invention has some structures of the traditional drum washing machine, such as the casing 1, the outer cylinder 2, the inner cylinder 3, the water inlet system, the drainage system, the driving system and the control system (not shown in the figure). shown), also includes an air pump 4, a gas heating device 5, a one-way valve 6, an air chamber 7, an air distributor 8 and an air guide tube 9, the gas heating device 5 plays a role in heating the air, and the one-way valve 6 can Prevent the water flow from entering the gas heating device 5 and the air pump 4, the air flow distributor 8 divides the hot air, the air pump 4 and the gas heating device 5 are installed on the washing machine cabinet 1, and the gas coming out of the air pump 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com