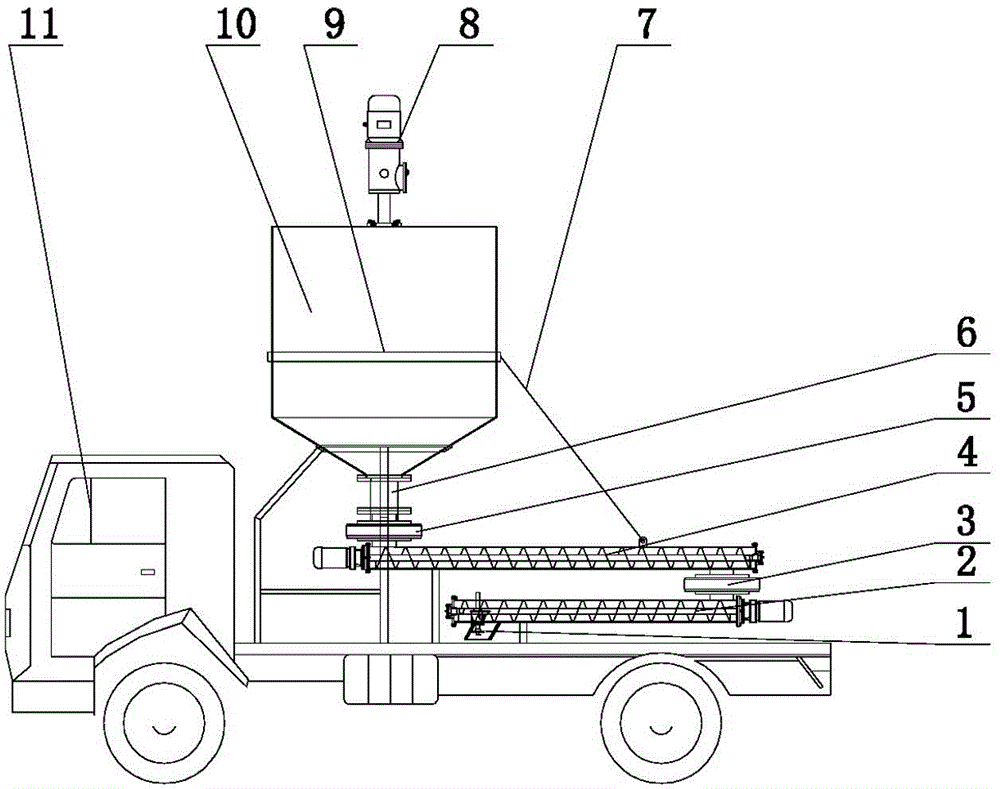

High-effective material charging vehicle

A feeding truck and high-efficiency technology, applied in the field of auxiliary equipment, can solve problems such as increased labor costs, poor adaptability, and blocking of isolation boards, and achieve the effects of saving storage space, avoiding secondary dust, and reducing distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention comprises a car body 11, a hopper 10 is arranged above the car body 11, and it is characterized in that: the discharge port at the bottom of the hopper 10 is connected to the feeding device through a transition bin 6, and a quantitative device is arranged in the transition bin 6, so Described dosing device comprises the dosing cylinder 17 that upper and lower ends are all open, is provided with connecting rod 18 in the dosing cylinder 17, and the upper end of connecting rod 18 links to each other with the driving device 8 on the feed bin 10, and the lower end of connecting rod 18 is corresponding to dosing cylinder 17 The lower opening is provided with a lower block 16, and the upper opening of the connecting rod 18 is provided with an upper block 19 corresponding to the upper opening of the quantitative cylinder 17. The distance between the lower block 16 and the upper block 19 is greater than the height of the quantitative cylinder 17.

[0031] Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com