A kind of preparation method of solid carbon quantum dot

A carbon quantum dot, solid-state technology, applied in the field of preparing solid carbon quantum dots, can solve the problems of electrode damage, high cost of 3D graphene synthesis, limiting the large-scale production and application of carbon quantum dots, etc. The effect of easy size control, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

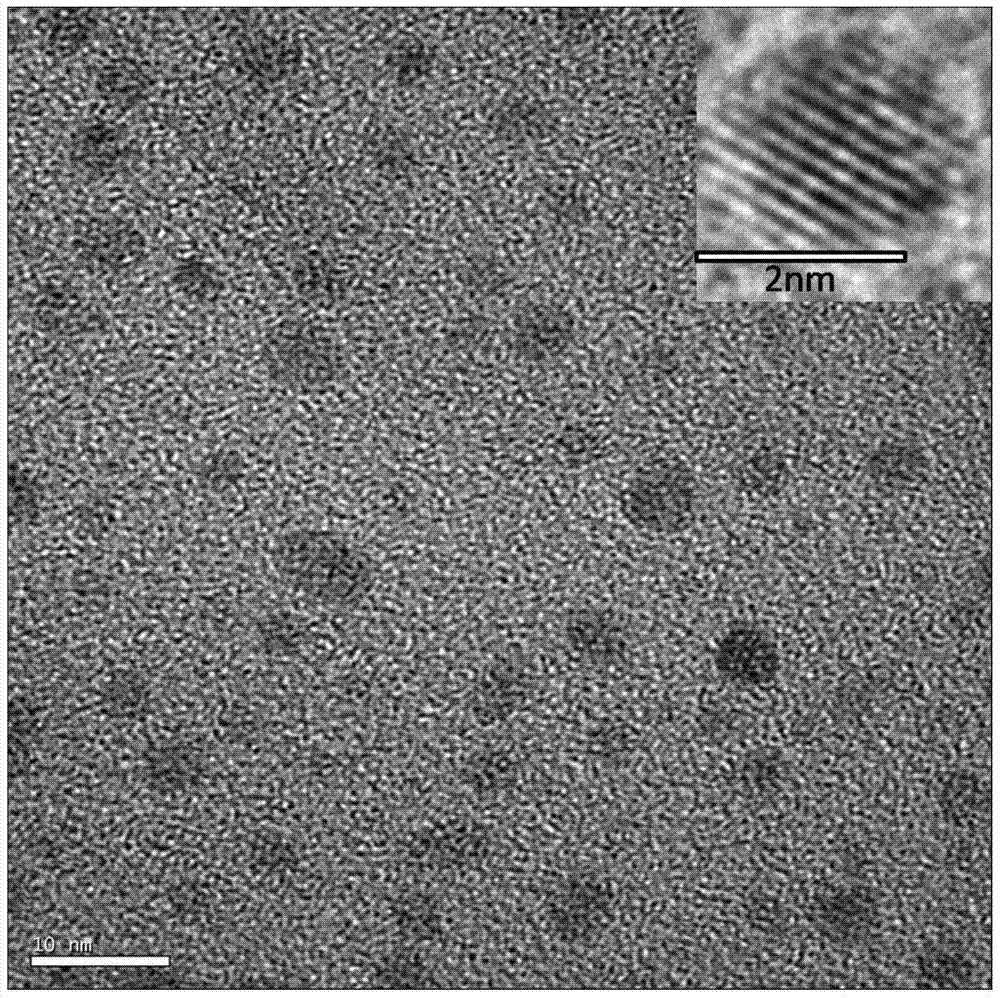

Image

Examples

Embodiment 1

[0027] The specific process of preparing solid carbon quantum dots in this embodiment is as follows:

[0028] (1) Use an area of 1.0cm 2 The platinum sheet electrode is used as the anode 6 and the cathode 7 in the electrochemical method;

[0029] (2) Put the ionic liquid and acetonitrile into the 100mL electrolytic cell 4 as the electrolyte solution 5 after being mixed according to the volume ratio of 1:500, turn on the power supply 1, and implement 15.0V DC constant current at both ends of the anode 6 and the cathode 7 The voltage was reacted for 24 hours, and a dark brown solution was obtained. After the reaction, the current was stable, and the electrolyte 5 changed from colorless and transparent to dark brown. Finally, a dark brown solid was formed and attached to the cathode 7, and the electrolyte 5 became After light brown, stop applying voltage, and the dark brown solid substance will automatically fall off from the electrode to the solution to obtain a light brown s...

Embodiment 2

[0032] In this embodiment, the carbon quantum dot solution prepared in Example 1 is applied to Fe 3+ For the detection of specific ions, add 400μMAg to the carbon quantum dot solution + ,Al 3+ ,Cd 2+ ,Co 2+ ,Fe 2+ ,Hg 2+ ,Mg 2+ ,Mn 2+ , Ni 2+ ,Pb 2+ ,Zn 2 , and measure its fluorescence intensity under the excitation wavelength of 355nm, the fluorescence intensity obtained is almost the same as that of the stock solution, as Figure 4 shown; adding 400 μM Fe 3+ It was obviously found that the fluorescence intensity decreased significantly, indicating that the prepared carbon quantum dots had a strong effect on Fe 3+ The detection of has extremely strong specificity and selectivity; In order to explore adding Fe 3+ The concentration (10-1200μM) has a linear relationship with the fluorescence intensity, and a series of concentration gradients of Fe 3+solution was added to 3.0mL of carbon quantum dot solution, Fe 3+ The solution concentrations were 0, 5 μM, 10 μM, 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com