High-lance-position vacuum refining method based on coherent jet top lance

A technology of vacuum refining and top gun, which is applied in the field of secondary smelting, can solve the problems that restrict the development and limitation of RH refining process, and achieve the effect of improving penetration depth and stirring intensity, uniform composition and temperature, and enhanced penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

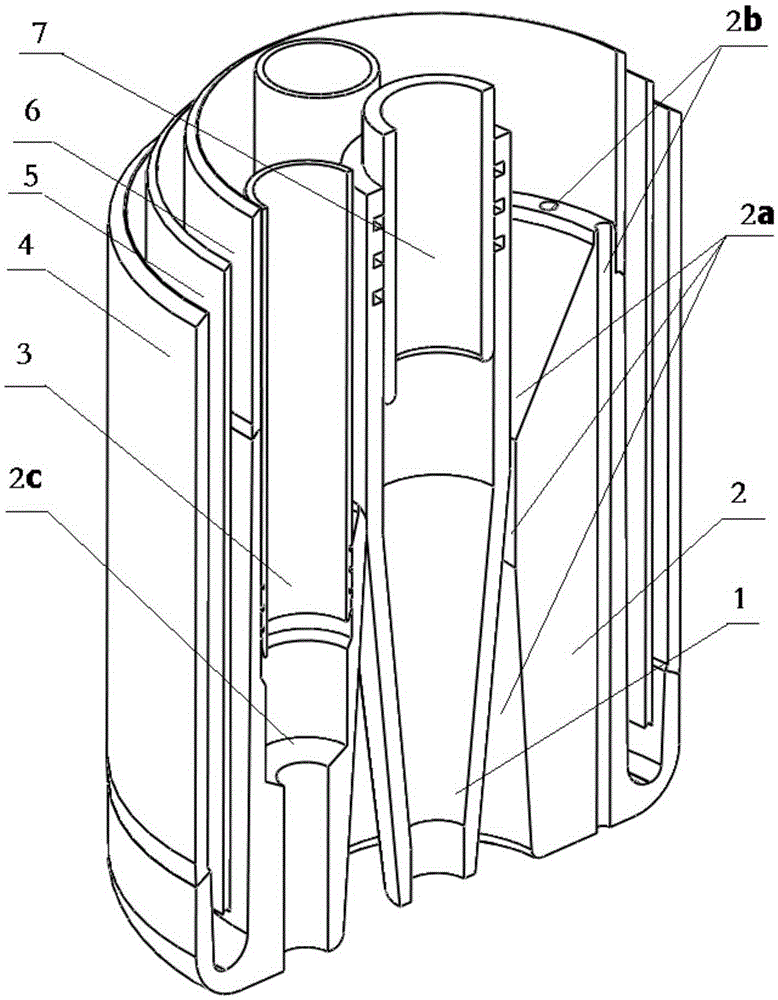

[0055] A high-lance vacuum refining method based on cluster top lances, including the use of process equipment consisting of a ladle, a vacuum chamber, a cluster top lance and a vacuum device, inserting the dipping tube of the vacuum chamber into the molten steel in the ladle, and the top lance Insert the vacuum chamber through the sealed channel, the vacuum device keeps the pressure on the surface of the molten steel in the vacuum chamber in a low pressure state, the lifting gas is introduced into the ascending dipping tube to make the molten steel circulate between the vacuum chamber and the ladle, and oxygen is introduced into the top lance , powder, gas and other media.

[0056] Among them, the cluster top gun has a powder channel in the center, a main oxygen channel located on the periphery of the powder channel, and a secondary oxygen channel located on the periphery of the main oxygen channel; during RH vacuum refining, oxygen and powder are blown into the vacuum tank th...

Embodiment 2

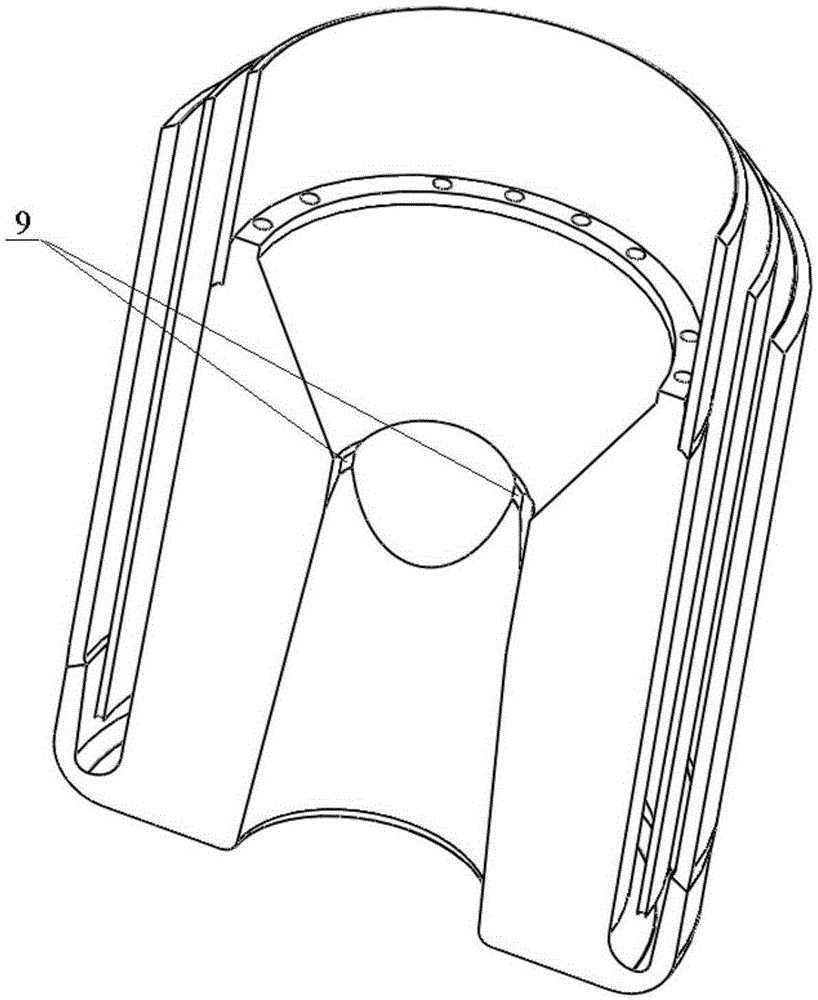

[0071] Such as Figure 5 to Figure 7 As shown, the difference between this example and Embodiment 1 is that the positioning ridge 9 as a positioning structure is arranged on the inner surface of the nozzle outer tube 2, as Figure 6 and Figure 7 As shown, there are 3 or more grooves evenly distributed along the circumference on the inner wall of the equal-diameter circular hole section; the grooves of the outer tube 2 of the nozzle and the cylindrical outer contour of the core tube 1 of the nozzle form a porous annular groove-shaped gas channel 8, The outer contour surface corresponding to the nozzle core tube 1 and the central hole 2a of the nozzle outer tube 2 is a cylindrical surface, the diameter of the cylinder of the nozzle core tube 1 is equal to the diameter of the cylinder hole of the nozzle outer tube 2, and the nozzle core tube 1 is inserted into the nozzle In the annular groove gap formed behind the central hole 2a of the outer tube 2, the total void area at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com