Point electrode capacitance sensor and injection molding machine using the sensor

A point electrode and capacitor technology, applied in the field of injection molding machines, can solve the problems of low flexibility, narrow applicability, and difficulty in installing flat plate capacitors, and achieve the effect of high flexibility and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

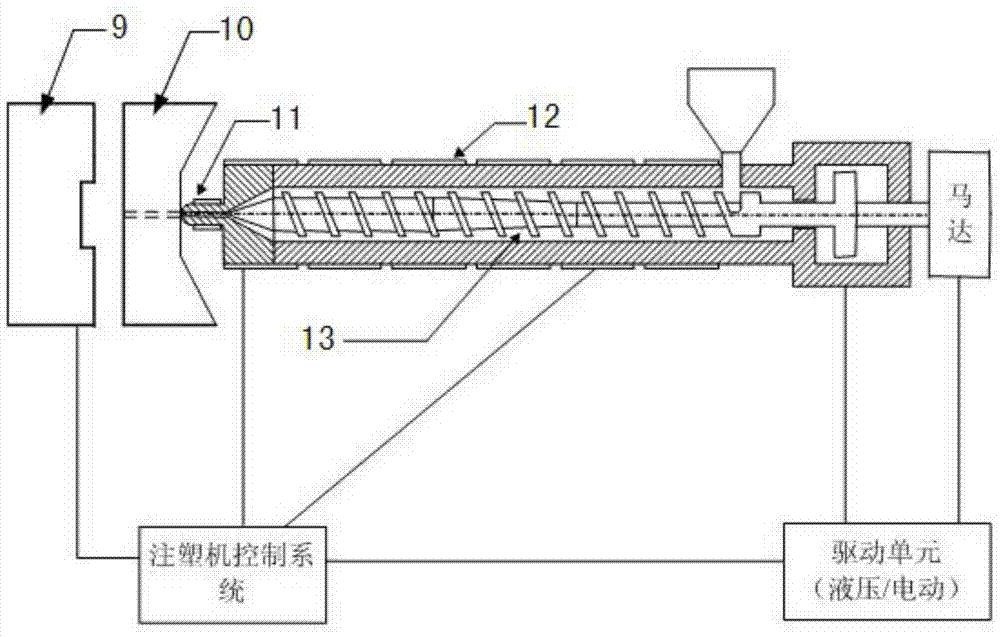

[0044] In order to meet the needs of online measurement of flat-shaped products (such as mobile phone casings), some people have designed and processed flat-panel capacitive sensors. The capacitive sensor uses two flat electrodes installed on both sides of the cavity to sense the state of the plastic melt in the cavity. The experimental results show that the plate type capacitor can accurately and effectively measure the material state of the plate type plastic product in the mold cavity on-line, but the plate type capacitor cannot be installed in the plastic product mold with complex cavity surface structure. Based on this requirement, the present invention designs a novel point electrode capacitive sensor to solve the problem of online measurement of plastic products with complex surfaces.

[0045] The point sensor of the present invention can not only play the role of a flat plate capacitive sensor in the form of an array, but also can be rationally arranged in a mold with ...

no. 2 example

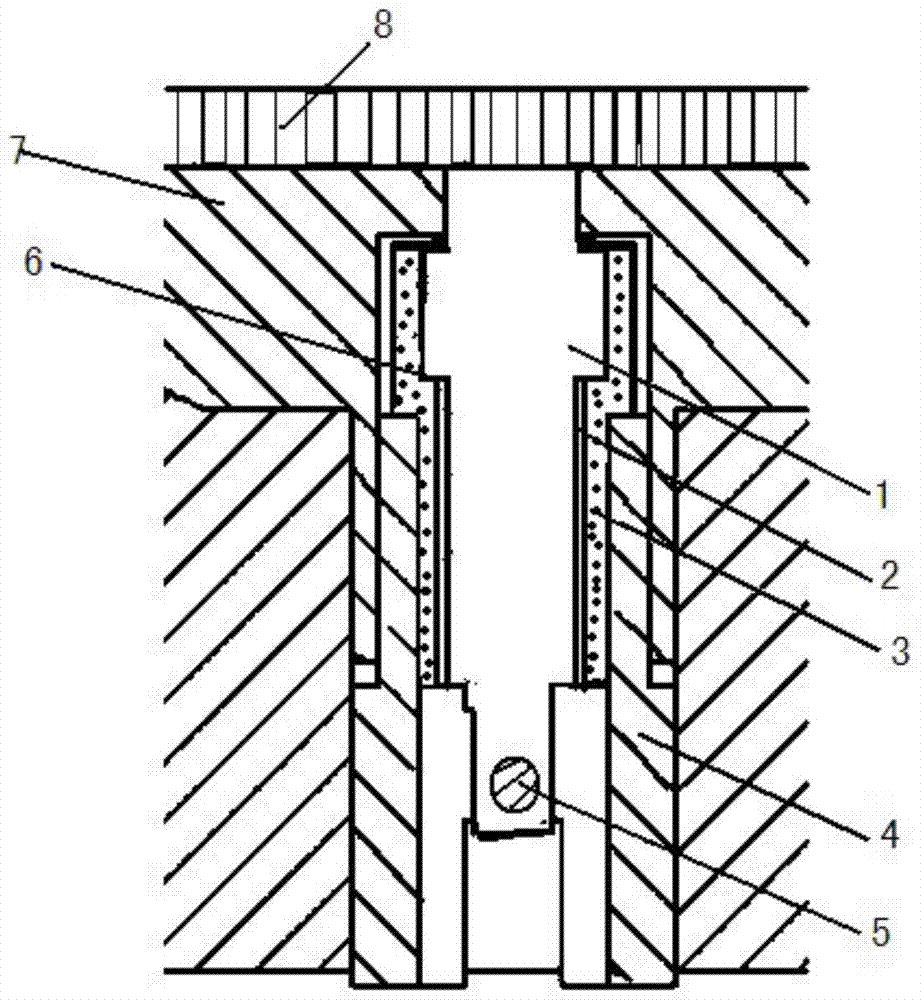

[0051] For the sake of reliability, the capacitive sensor of this embodiment is divided into three parts, which are point electrodes, nests and bolts. The design of the point electrode needs to consider its working environment. In the mold, the point electrode must not only bear the pressure from the plastic in the mold cavity, but also must ensure that its electrode plate does not enter the mold cavity, so as to avoid affecting the product quality. Therefore, the point electrode plate needs to be positioned in two directions. like figure 1 As shown, the positioning of the point electrode in the present invention is realized by the shaft shoulder, and the upper part of the shaft shoulder cooperates with the positioning hole of the mold to realize the positioning in the upward direction; Mold fits to achieve positioning in the downward direction.

[0052] The invention designs the point electrode, nesting and threaded bolt into a structure that cooperates with each other, so...

no. 3 example

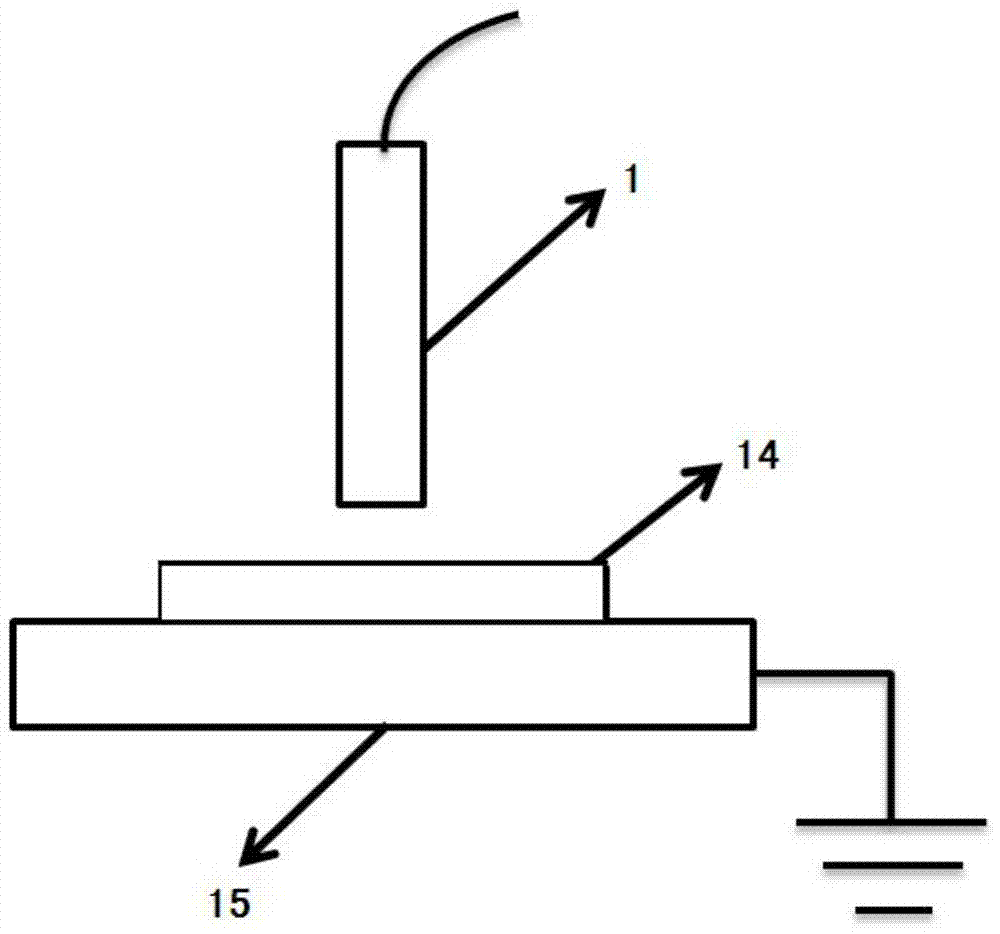

[0056] To form a capacitor, the two poles of a point electrode capacitor must be isolated from each other. In this embodiment, an electrical insulator is used to isolate the point electrodes from other parts of the mold, and the electrical insulator is made by spraying alumina insulating varnish. However, it was found in the experiment that the thickness and machining accuracy of the sprayed layer of insulating varnish are difficult to control, which will cause the outer diameter of the point electrode of the sensor after spraying the insulating layer to fail to match the aperture of the static mold well, and clearance fit or interference fit may easily occur. In addition, in order to achieve a better insulating effect, it is necessary to increase the thickness of the insulating layer. However, the increase in thickness is prone to peeling of the insulating varnish, and the durability of the sensor cannot be guaranteed.

[0057] Based on the comprehensive consideration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com