Parallel static-electric air filtering plate

An air filtration and electrostatic technology, applied in the direction of electrostatic separation, electrode structure, etc., can solve large, sometimes convenient, reduced filtering effects, and incomplete solutions to problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

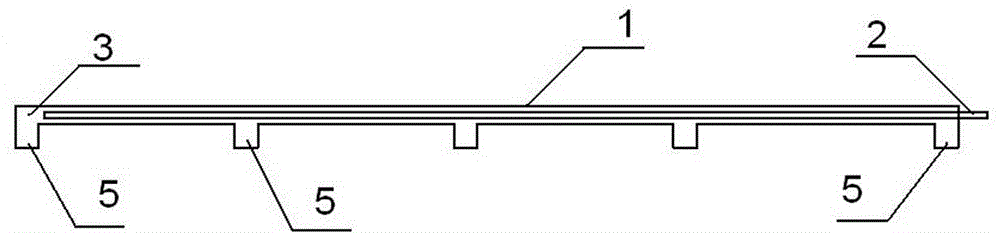

[0032] like Figure 4 Shown, embodiment one of the present invention, a kind of parallel electrostatic air filter plate, is made up of six parallel dust collecting plates 1, and dust collecting plate 1 is made of the insulating electret material 3 of metal plate 2 and its external wrapping, The polarity of the power supply connected to two adjacent dust collecting plates 1 is opposite. The dust collecting plates are rectangular and flake-shaped. Two raised supporting points 5 of the same height, the distance between the two dust collecting plates 1 is smaller than the height of the raised supporting points 5; the other side of the raised supporting points 5 on the dust collecting plate 1 corresponds to a concave positioning groove 6. In the figure, the support point 5 on one dust collecting board is combined with the recessed positioning groove 6 on the other dust collecting board, and a small piece of the metal plate 2 sticks out to connect the power supply.

[0033] figur...

specific Embodiment 2

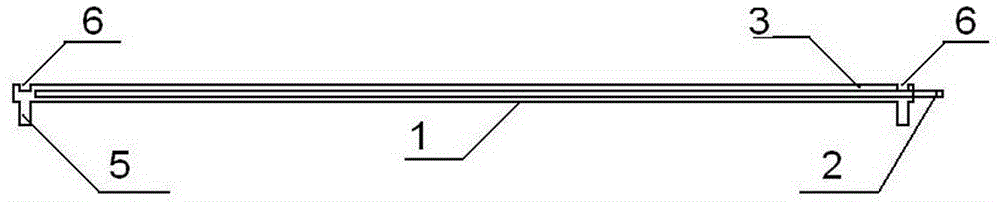

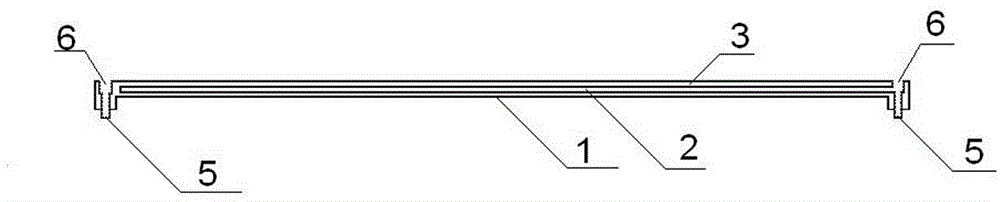

[0035] Specific embodiment two, the dust collecting plate can be like Figure 4 The same building block connection can also be made by one-time molding of the mold, and the dust collecting plates are fixedly connected by insulating electret materials, such as Figure 5 As shown in the combination, you can add more raised support points, such as Image 6 same combination. Figure 7 is true Image 6 Further refinement of the structure, in the figure, the dust collecting plates 1 are connected by raised support points 5, the dust collecting plates 1 include metal plates 2 and insulating electret materials 3, and there are air passages 4 between the dust collecting plates. Figure 7 It does not reflect the dust-collecting plates and how they are connected to each other. In practice, there are many electrical connections. Each dust-collecting plate can be electrically connected to the outside. Of course, the one-time formed electrostatic air filter plate is best to be connected t...

specific Embodiment 3

[0036] Specific embodiment three, such as Figure 13 As shown, the electrostatic air filter plate is composed of six dust-collecting plates 1, and two adjacent dust-collecting plates have protruding parts of metal plates 2 at both ends, which are used to connect positive or negative electrodes, and the two ends are respectively There are raised supporting points 5, and combined with the concave positioning groove 6, they are combined into an organic whole; the filtered air channel is divided into multiple small filtered air channels 8 by multiple sheets, Figure 12 is a cross-sectional view of a single dust collection plate, from Figure 9 , Figure 10 , Figure 11 It can be seen that the sheet 7 can have various forms, Figure 9 It is Z-shaped, with a disconnection in the middle, and it can also be in a connected state; Figure 10 It is V-shaped; Figure 11 It is S-shaped. Of course, it can also present various other forms, such as W shape, straight shape and so on.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com