Filter cover plate, filter and processing method for filter cover plate

A filter and cover plate technology, which is applied in the field of filters, can solve problems affecting the volume of the resonant cavity, and achieve the effects of improving performance, reducing thickness, and increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a filter cover plate, on which a flanged threaded through-hole for installing a tuning screw is provided, and a thread matched with the tuning screw is arranged in the flanged threaded through-hole. The flanged threaded through hole may be a one-way flanged threaded through hole or a two-way flanged threaded through hole. The one-way flanging threaded through hole means that it only flangs toward one side of the cover plate, and it can be flanged toward the inner side of the filter cover plate (the inner side of the cover plate refers to the side facing the filter cavity), or it can be turned toward the filter The outer flange of the cover. The bidirectional threaded through hole means that it is flanged toward the inner and outer sides of the filter cover plate.

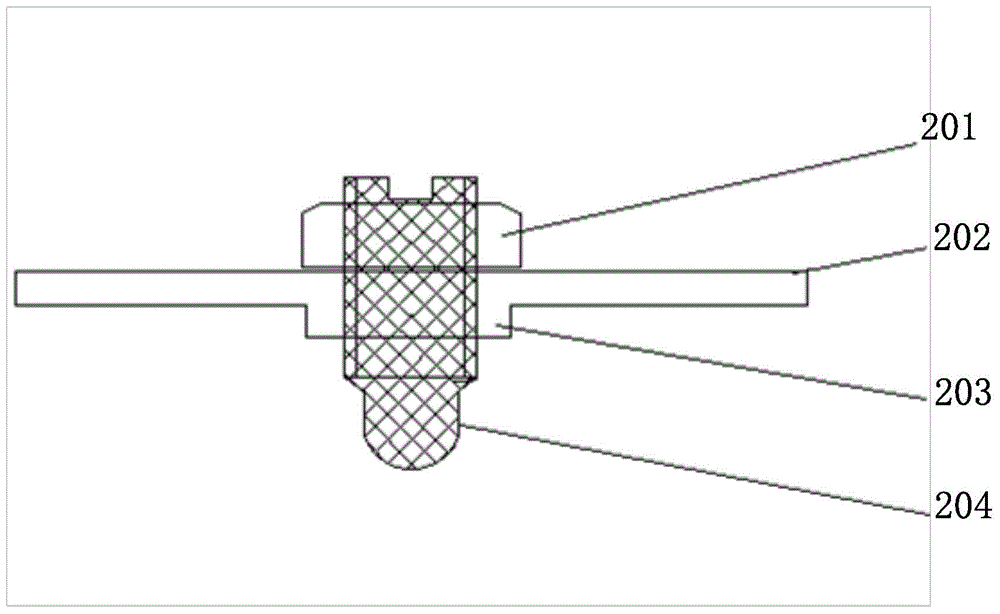

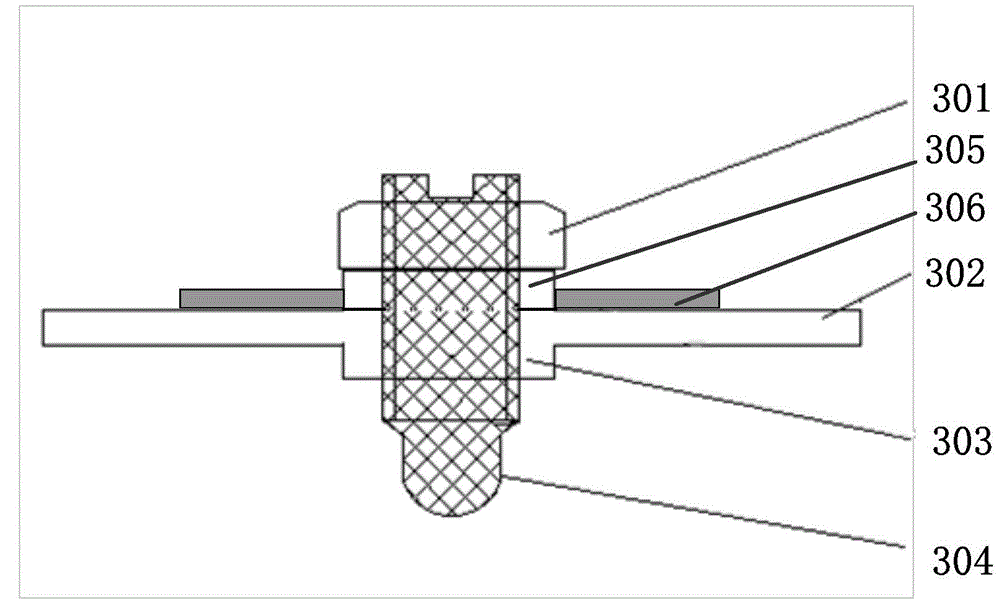

[0027] In order to further illustrate the filter cover plate provided in this embodiment, an exemplary description is used below to describe it. See figure 2 , figure 2 This emb...

Embodiment 2

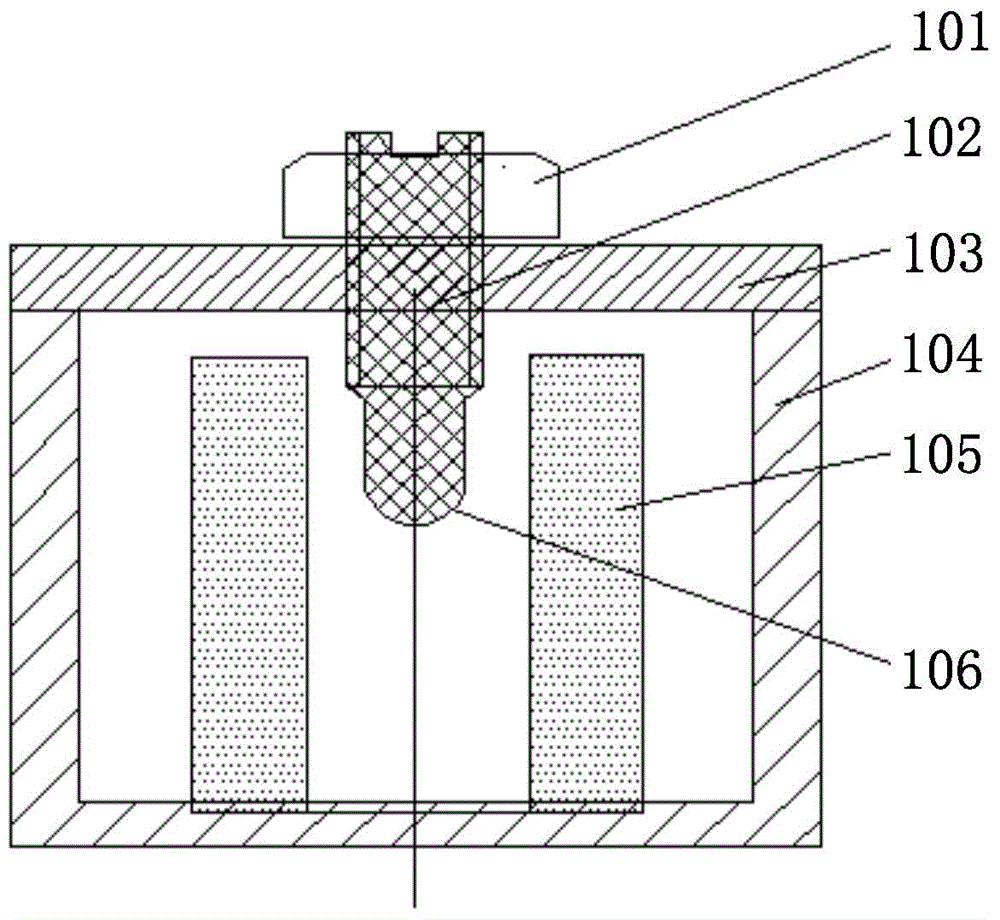

[0033] This embodiment provides a filter, which includes a filter cover and a cavity, and the filter cover is the filter cover provided in the first embodiment above. The filter cover is fixed on the cavity. At least one resonant column is also provided in the filter, and the flanged threaded through hole is located at the position corresponding to the resonant column in the cavity on the filter cover plate. After the cover plate is installed on the cavity, through the flanged screw thread The tuning screw that holes into the cavity fits right inside the resonating post. At least one resonant cavity can be arranged in the cavity of the filter, and when there is only one resonant cavity in the filter, the cavity of the filter is the cavity of the resonant cavity. When multiple resonant cavities are provided in the filter, it means that there are multiple sub-cavities in the filter, and each sub-cavity is isolated by isolation ribs in the filter cavity. For the coaxial cavity ...

Embodiment 3

[0036] This embodiment provides a filter cover processing method, please refer to Image 6 , Image 6 It is a schematic flow sheet of the processing method, the method comprising the steps of:

[0037] Step S601: Processing the cover plate material to obtain the cover plate base.

[0038] Step S602: using a mold to punch out flanged holes at the positions where the tuning screws are installed on the base of the cover plate. The punching and flanging hole specifically may include: punching a flanging pre-hole, and flanging at the flanging pre-hole with a mold.

[0039] Step S603: tapping in the flanging hole.

[0040] In the above step S602, the flanging hole can be unidirectional or bidirectional, so punching the flanging hole at the position where the tuning screw is installed on the base of the cover plate with a mold can be used to install the tuning screw on the base of the cover plate with a mold. At the position of the screw, punch one-way flanging holes toward the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com