A method for stress monitoring of special-shaped steel structures

A stress monitoring and steel structure technology, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of difficult monitoring of steel structures, inability to set temperature compensation blocks, inaccuracy, etc., and achieve easy removal, elimination of data deviation, and fixed structure. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

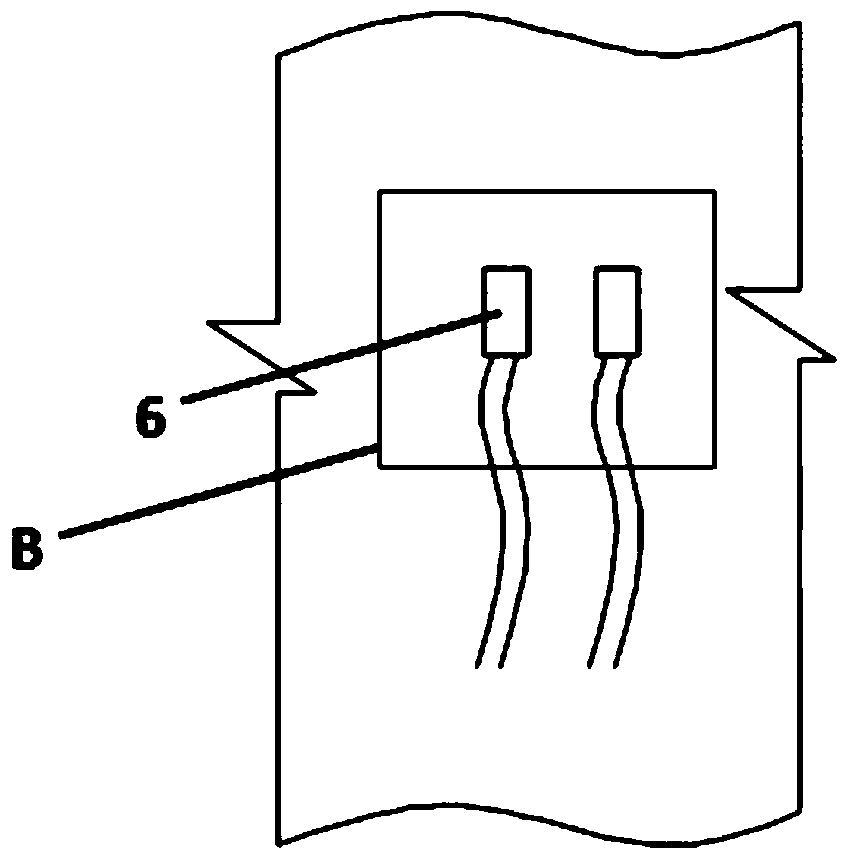

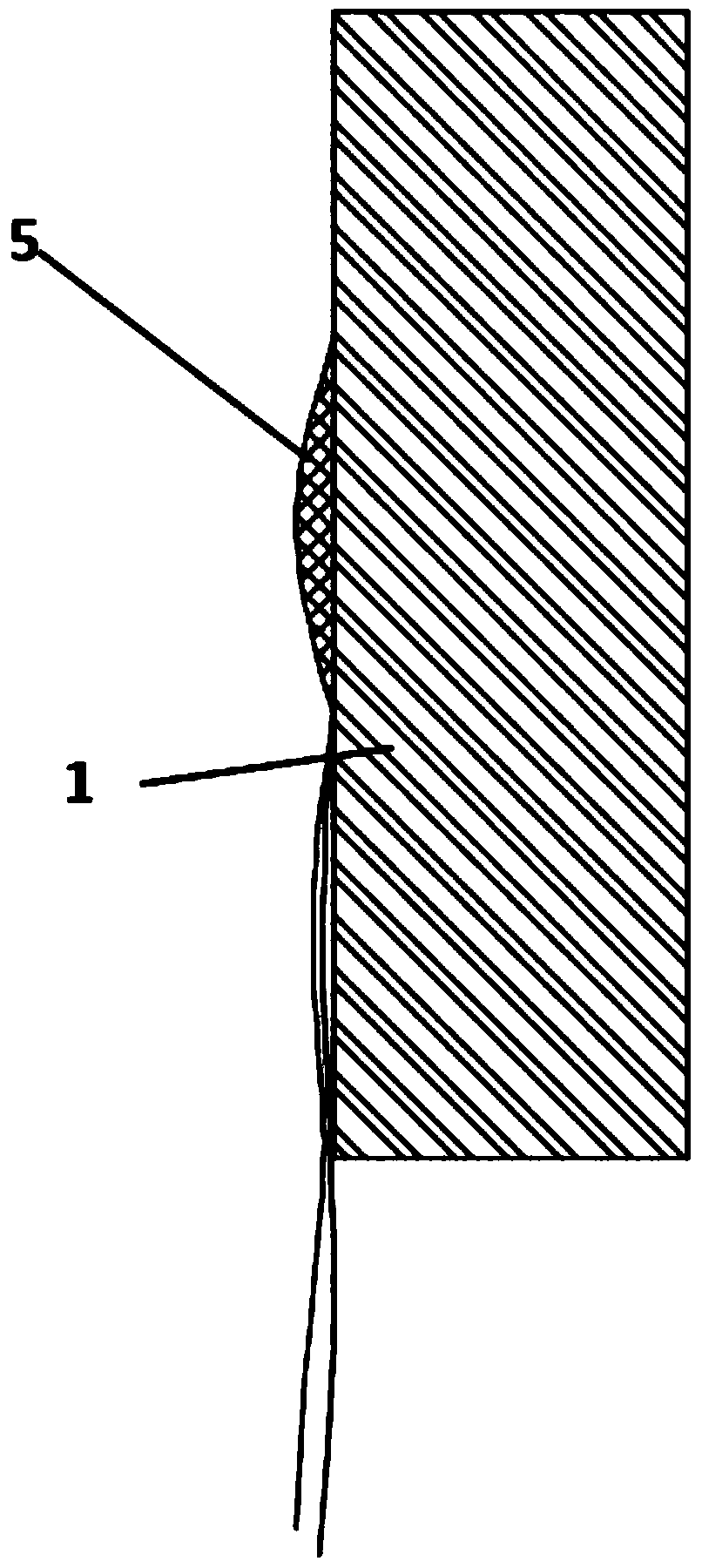

[0034] (1) Coarsely grind and finely grind the monitored structure 1 according to the standard of laying out the strain gauge 6 at the monitoring point, and wipe the surface of the monitored structure with alcohol cotton to form a smooth surface B;

[0035] (2) At least two monitoring measuring point strain gauges 6 are arranged at parallel intervals on the smooth surface B, and the monitoring measuring point strain gauges 6 are covered with protective glue 5 to protect the monitoring measuring point strain gauges 6. After the protective glue 5 is hardened, the arrangement of the strain gauge 6 at the monitoring point is completed;

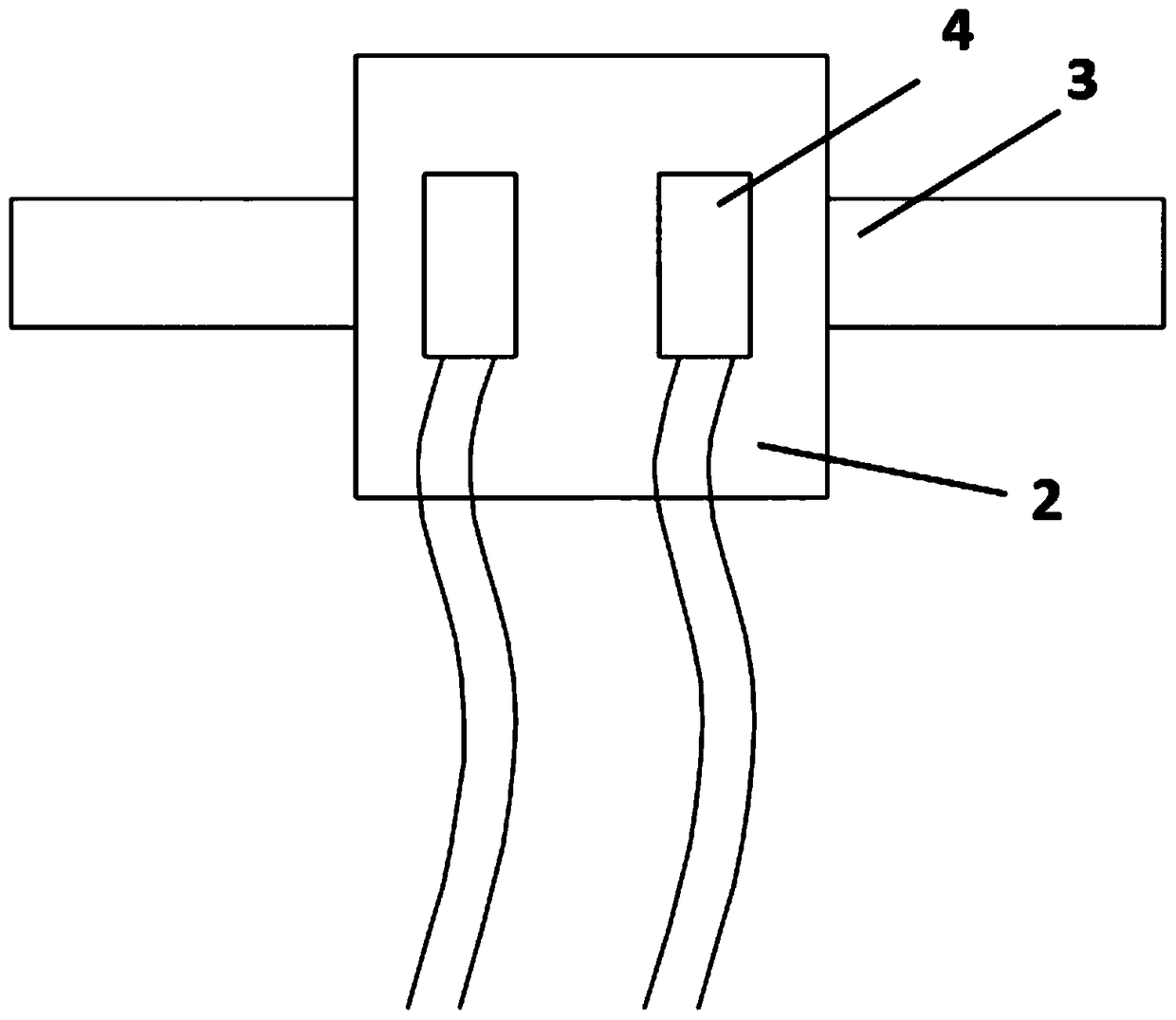

[0036] (3) Weld the two ends of the steel strip 3 of the prefabricated steel structure monitoring temperature compensation block structure on the smooth surface B of the monitored structure 1, so that the temperature compensation measuring point strain gauge 4 set on the steel block 2 is in line with the monitoring measuring point The point strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com