Monitoring device and monitoring method for detecting downhole corrosion situation

A monitoring device and detection well technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem that the corrosion and scaling of downhole piezometers and pipe strings cannot be monitored, and affect the normal production of oil and gas in oil wells , pipe strings and equipment safety hazards, etc., to ensure the normal operation of safe production, reduce economic and crude oil losses and crude oil pollution, and achieve significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the purpose, structure and function of the present invention, the downhole corrosion monitoring device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

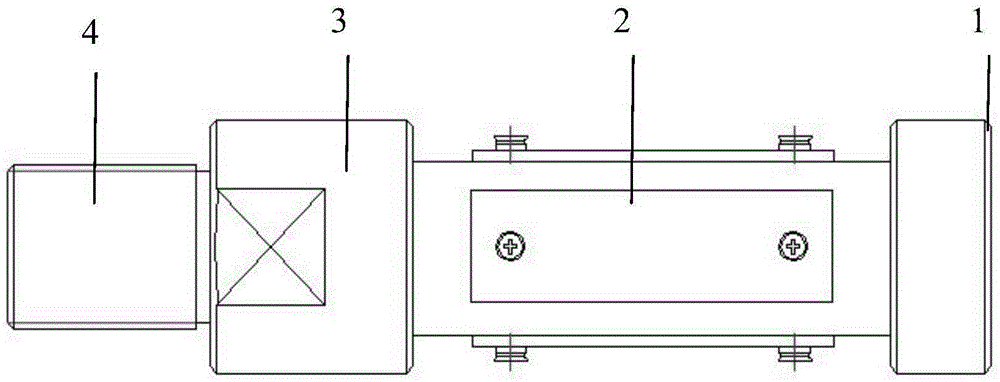

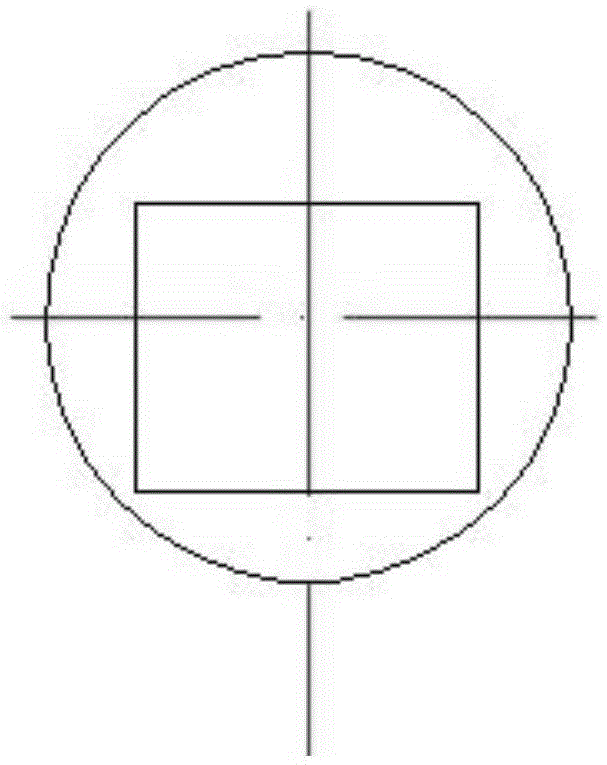

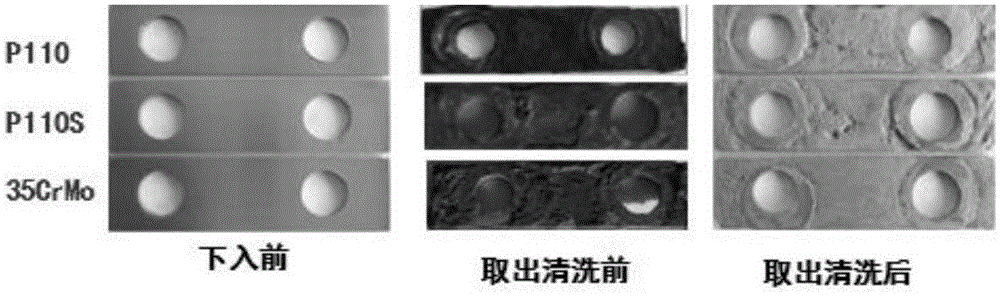

[0021] Such as figure 1 with figure 2 As shown, it is a monitoring device for detecting downhole corrosion of the present invention. The downhole corrosion monitoring device includes an integrally formed inverted cone joint 1, a hanging piece clip 2, a mounting part 3 and a threaded nipple 4, which are sequentially connected. Inverted cone joint 1 is used to orient the monitoring device in the downhole or at the bottom of the well. The threaded puppet 4 is connected with the downhole piezometer (not shown in the figure). The clip 2 is fixed on the outer wall of the installation part 3 to be fixedly connected with the downhole piezometer, and can go downhole with the downhole piezometer, completely immersed in the downhole f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com