Acting cylinder and booster cylinder separated engine

A technology for working cylinders and engines, which is applied in the direction of engine components, combustion engines, machines/engines, etc. It can solve the problems of poor lubrication, mutual interference, mutual stirring, and long-lasting use of crankcase operating parts, and achieves a simple structure , complete combustion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

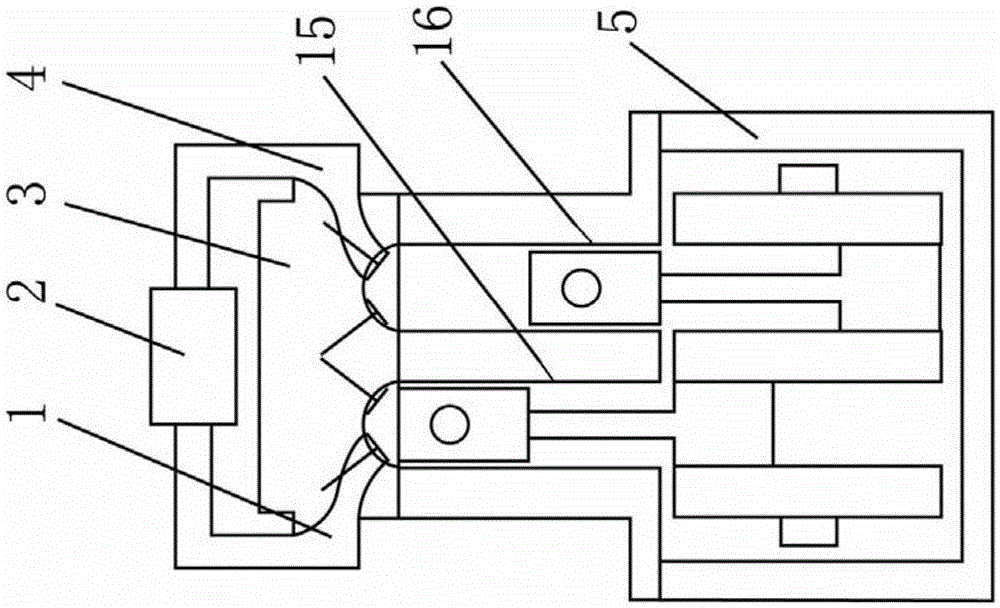

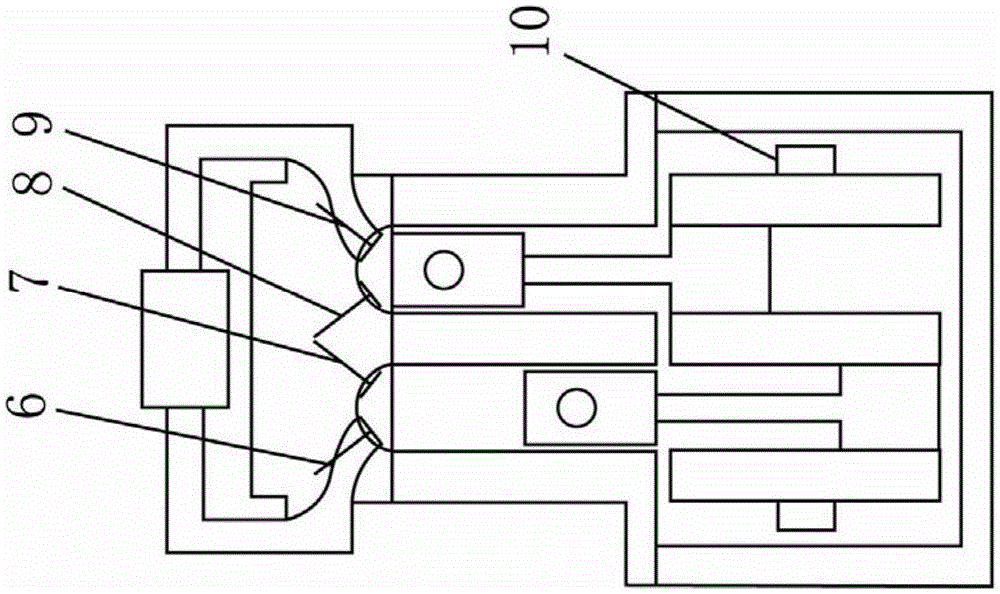

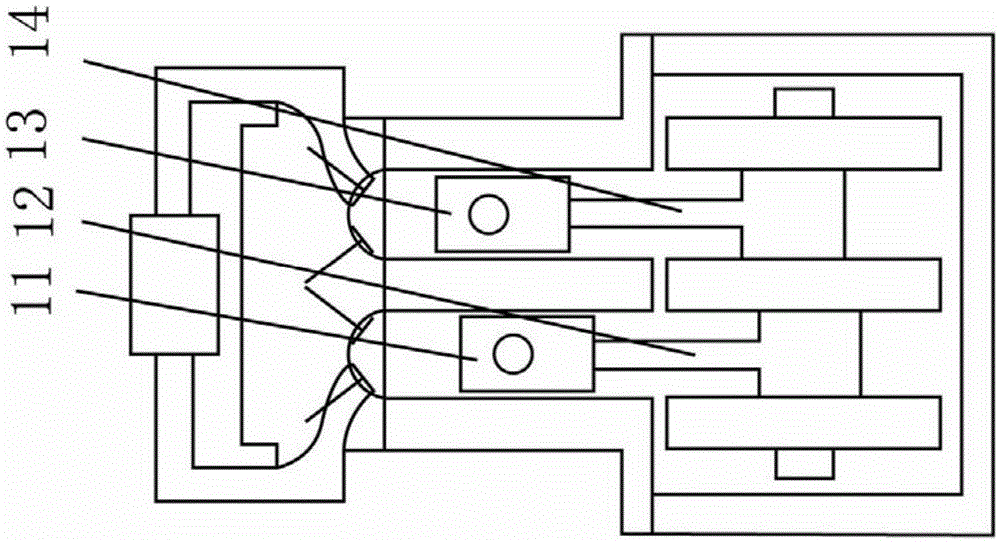

[0012] The present invention will be described in detail below with reference to the accompanying drawings.

[0013] Work cylinder 16 and booster cylinder 15 are installed on crankcase 5 of the present invention. There is a cylinder head 3 on the power cylinder, a combustion chamber, a power intake valve 9, and a power exhaust valve 8 on the cylinder head. The power intake valve is connected to the intercooler 2 through the exhaust passage 4, and the power exhaust valve is connected to the exhaust pipe. . There is a cylinder head on the supercharged cylinder 15, and a supercharged intake valve 7 and a supercharged exhaust valve 6 are arranged on the cylinder cover. cylinder. The supercharging piston 11 of the supercharging cylinder is connected with the crank throw 10 through the supercharging connecting rod 12; the working piston 13 of the working cylinder is connected with the crank throw 10 through the working connecting rod 14.

[0014] In the present invention, a boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com