Microbial decomposition agent for animal wastes and straws and preparation method thereof

A microbial decomposing agent, animal manure technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A preparation of a microbial decomposing agent for animal manure and stalks, comprising the following steps:

[0075] (1) According to the steps of strain preparation, Bacillus, saccharomyces, and Aspergillus niger are respectively fermented and cultivated to obtain a fermented liquid;

[0076] (2) The above-mentioned fermented liquid obtained above is subjected to centrifugation respectively to get the mycelium;

[0077] (3) Add the adsorbent bentonite and peat soil as an auxiliary material 5 times the weight of the fermentation broth to the obtained mycelia according to the weight of the thallus at a ratio of 1:1, mix them evenly, and then dry them with hot air at a low temperature of 45°C for 50 minutes to obtain powders of various strains;

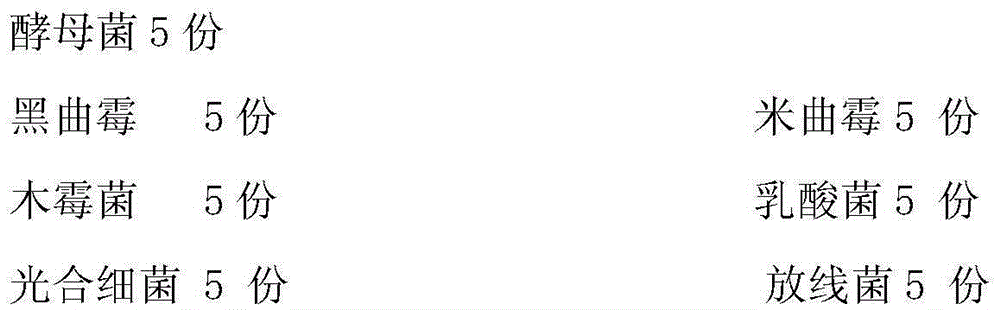

[0078] (4) Mix the various strain powders obtained above with commercially available Aspergillus oryzae, Trichoderma, lactic acid bacteria, photosynthetic bacteria, and actinomycetes according to the ratio of parts by weight. T...

Embodiment 2

[0084] A preparation of a microbial decomposing agent for animal manure and stalks, comprising the following steps:

[0085] (1) According to the steps of strain preparation, Bacillus, saccharomyces, and Aspergillus niger are respectively fermented and cultivated to obtain a fermented liquid;

[0086] (2) The above-mentioned fermented liquid obtained above is subjected to centrifugation respectively to get the mycelium;

[0087] (3) Add the adsorbent bentonite and peat soil as an auxiliary material 7 times the weight of the fermentation broth to the obtained mycelia according to the weight of the thallus at a ratio of 1:1, mix them evenly, and then dry them with hot air at a low temperature of 50°C for 60 minutes to obtain powders of various strains;

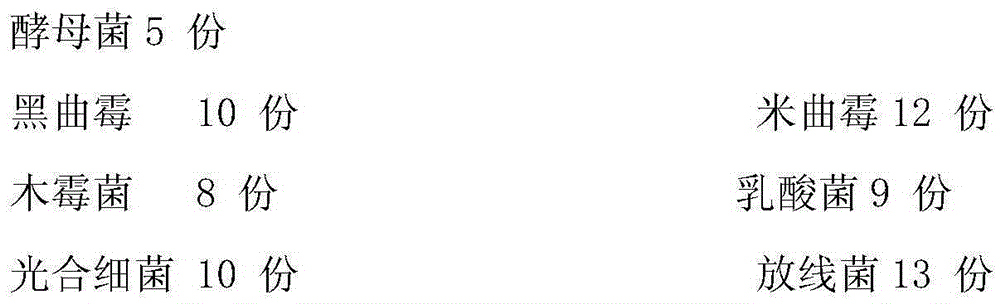

[0088] (4) Mix the various strain powders obtained above with commercially available Aspergillus oryzae, Trichoderma, lactic acid bacteria, photosynthetic bacteria, and actinomycetes according to the ratio of parts by weight. T...

Embodiment 3

[0094] A preparation of a microbial decomposing agent for animal manure and stalks, comprising the following steps:

[0095] (1) According to the steps of strain preparation, Bacillus, saccharomyces, and Aspergillus niger are respectively fermented and cultivated to obtain a fermented liquid;

[0096] (2) The above-mentioned fermented liquid obtained above is subjected to centrifugation respectively to get the mycelium;

[0097] (3) Add the adsorbent bentonite and peat soil as an auxiliary material 9 times the weight of the fermentation broth to the obtained mycelia according to the weight of the thallus at a ratio of 1:1, mix them evenly, and then dry them with hot air at a low temperature of 55°C for 70 minutes to obtain powders of various strains;

[0098] (4) Mix the various bacterial strain powders obtained above with commercially available Aspergillus oryzae, Trichoderma, lactic acid bacteria, photosynthetic bacteria, and actinomycetes according to the ratio of parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com