Preparation method of high-water-absorption polymer

A high water absorption, polymer technology, applied in the field of new functional polymer materials, can solve the problems of reducing space-time yield, time-consuming and laborious, etc., and achieve the effect of saving manpower, improving water absorption capacity, and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

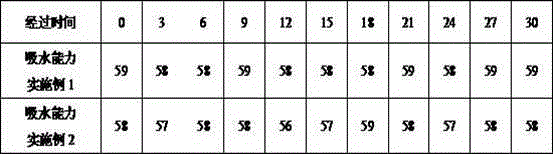

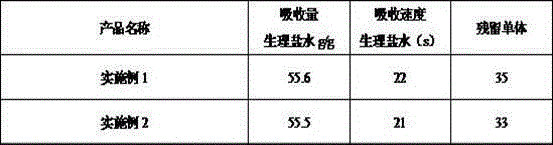

Embodiment 1

[0030] A kind of preparation method of superabsorbent polymer, used acrylic acid is the partially neutralized acrylic acid that 80% is neutralized by sodium hydroxide, prepares 100 parts of aqueous slurry with this partially neutralized acrylic acid, and its acrylic acid monomer concentration is 59.4%, Add 0.006 parts of N,N'methylene bis-dienamide, 0.2 parts of potassium persulfate and 1.6 parts of sorbitan glycerol-laurate to the above-mentioned 100 parts of acrylic acid monomer aqueous solution to prepare an aqueous slurry, Blow in nitrogen for deoxidation treatment, then gently stir and nitrogen "bubble", and send it into the agitator at a supply speed of 250g / min, and at the same time send 3% sodium bisulfite aqueous solution into the stirrer at a supply speed of 6g / min In the device (respectively using quantitative pumps) to make a slurry-like water-based mixture, the slurry-like water-based mixture is continuously sent to the screw extruder, the temperature of the casing...

Embodiment 2

[0034] A kind of preparation method of superabsorbent polymer, the acrylic acid used is 80%, the acrylic acid neutralized by sodium hydroxide, and 100 parts (weight) of water-based slurry are prepared with this part of neutralized acrylic acid, wherein the monomer concentration is 59.4% ( Heavy). Then, to the above 100 parts (weight) of aqueous slurry, add 0.03 parts (weight) of ethylene glycol diglycidic acid fan and 0.2 parts (weight) of potassium persulfate and 1.6 parts (weight) of sorbitan glycerol monolaurel Sour fat, after being prepared into a water-based mixture, is blown into nitrogen to carry out deoxidation treatment, and then gently stirred "bubbling", and it is continuously sent into the screw extrusion device at a supply speed of 250g / min. At the same time, 3% (weight) sodium bisulfite aqueous solution is sent into the agitator at a speed of 6g / min (respectively using quantitative pumps) to make a slurry-like water-based mixture and the slurry-like water-based m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com