Sulphur coated urea capable of preventing coating layer from breaking and preparation method thereof

A technology of coating layer and sulfur coating, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of high cost, fragile coating layer, and difficult degradation of the coating layer, and achieve the effect of reducing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

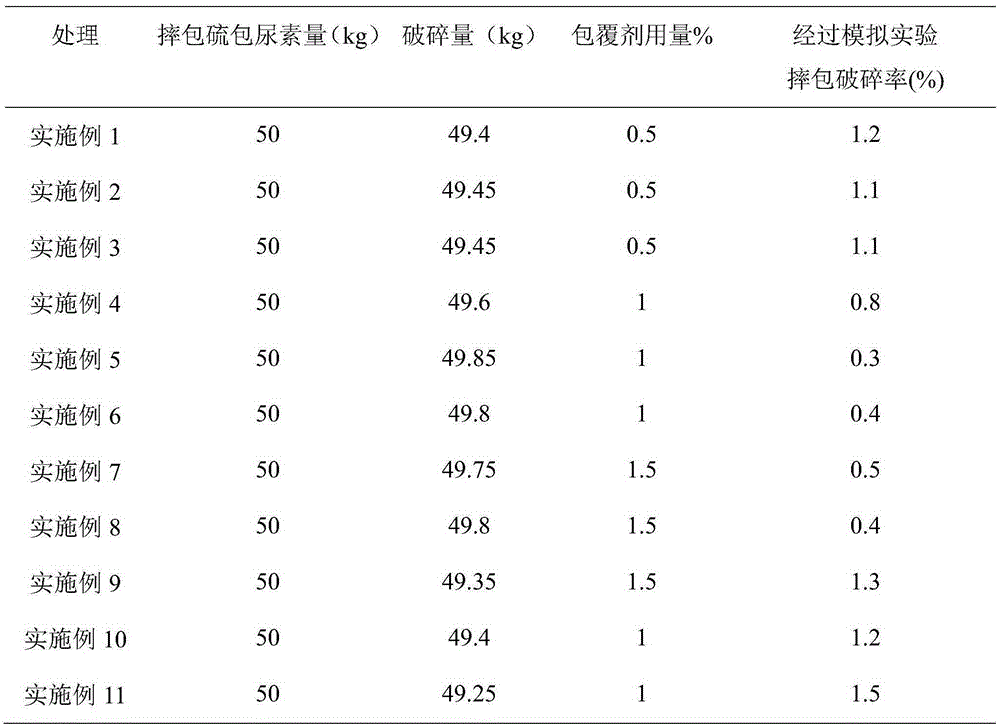

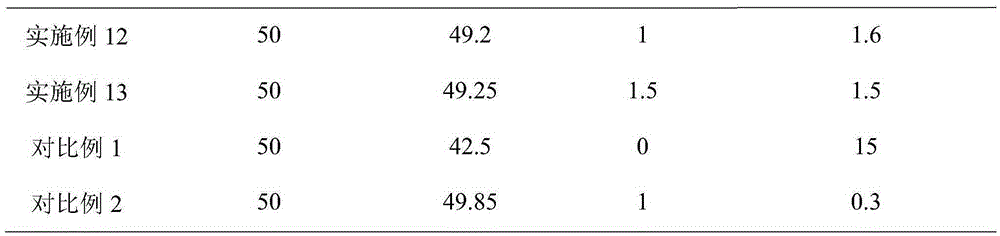

Examples

preparation example Construction

[0027] And, the embodiment of the present invention also provides a method for preparing sulfur-coated urea to prevent the coating layer from breaking, comprising the following steps:

[0028] S01. Weigh each component according to the formula of sulfur-coated urea to prevent the coating layer from breaking, mix the urea-formaldehyde resin and the auxiliary materials to obtain a blend, and dissolve the blend in water to form a coating Covering agent;

[0029] S02. heat-treating the urea in sulfur;

[0030] S03. Apply the coating agent to the urea-in-sulphur and then perform drying treatment.

[0031] Specifically, in the above step S01, the formula of the urea-in-sulfur and its preferred content components for preventing the coating layer from breaking are as above, and in order to save space, details are not repeated here.

[0032] In the embodiment of the present invention, the urea-formaldehyde resin and the auxiliary materials are mixed to obtain a blend, and the blend i...

Embodiment 1

[0040] A sulfur-coated urea that prevents the coating layer from breaking, including sulfur-coated urea and a coating agent, the coating agent coating the surface of the sulfur-coated urea, wherein the coating agent includes urea-formaldehyde resin and auxiliary materials, and The parts by weight of described sulfur-coated urea, urea-formaldehyde resin and auxiliary materials are as follows:

[0041] 1000 parts of sulfur-coated urea;

[0042] 5 parts of urea-formaldehyde resin;

[0043] 0.05 parts of auxiliary materials,

[0044] Wherein, the urea-formaldehyde resin is urea-formaldehyde, and the auxiliary material is zeolite powder.

[0045] And, a kind of preparation method of the sulfur-coated urea that prevents coating layer from breaking, comprises the following steps:

[0046] Weigh each component according to the above-mentioned formula of sulfur-coated urea to prevent the coating layer from breaking, mix the urea-formaldehyde resin and the auxiliary materials to obta...

Embodiment 2

[0050]A urea-in-sulphur that prevents the breaking of the coating layer and a preparation method thereof, the formula of which is based on the above-mentioned Example 1, and the number of parts of the auxiliary material is adjusted to 0.5 parts, and the method is referred to in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com