High-efficiency osmotic organosilicon waterproofing agent of timber and preparation method thereof

A silicone cross-linking agent and penetrating technology, which is applied in the field of wood high-efficiency permeable silicone waterproofing agent and its preparation, can solve the problems of high price, large environmental impact, and small chemical bond energy, and achieve long-term waterproof protection and penetrating power Strong and hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

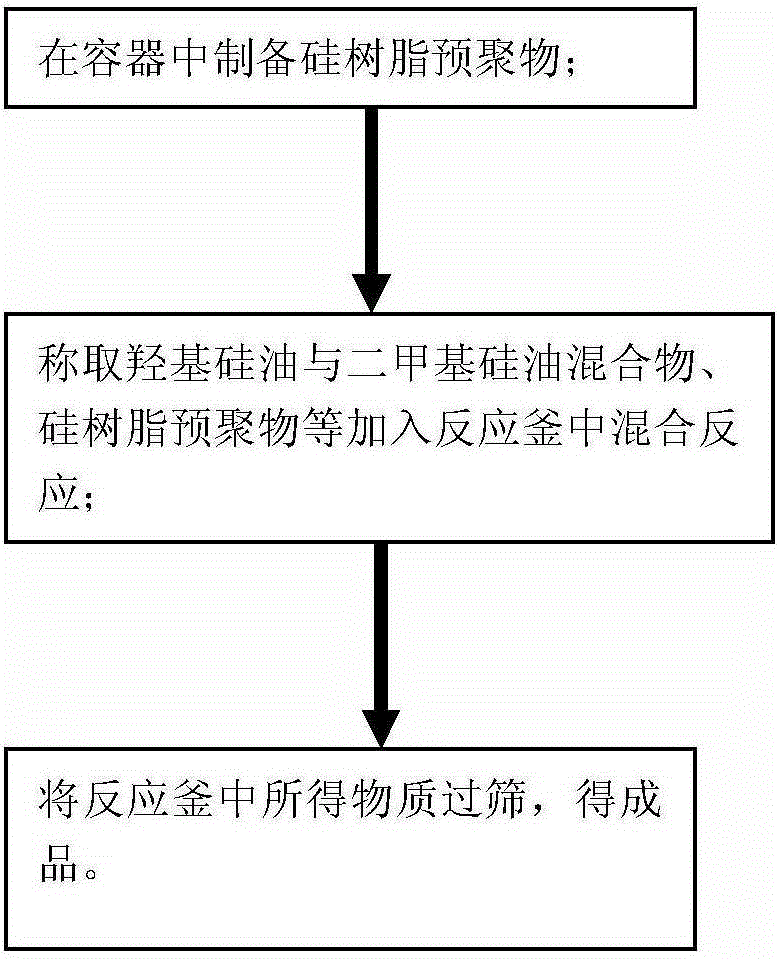

Method used

Image

Examples

Embodiment 1

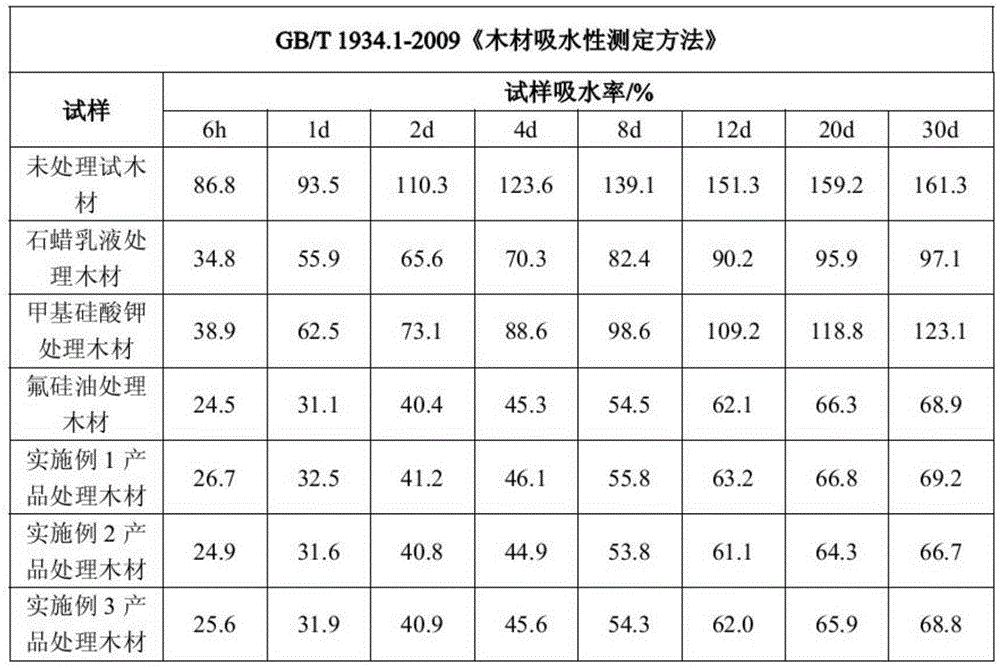

[0028] A high-efficiency penetrating silicone water repellant for wood is prepared from the following raw materials: 30% of silicone resin prepolymer, 40% of a mixture of hydroxy silicone oil and dimethyl silicone oil, 5% of silicone cross-linking agent, and long-chain alkyl silane 10%, organosilicon quaternary ammonium salt 2%, pH adjusting organic solution 1%, auxiliary agent 10%, nano-filler 2%, the silicone resin prepolymer is propyl and octyl silicone resin copolymer, propyl silicone resin The mass ratio to octyl silicone resin is 2:1, and the percentages are all mass percentages. The mixture of hydroxy silicone oil and dimethyl silicone oil is a mixture of 50,000-viscosity hydroxy-silicone oil and 60,000-viscosity dimethyl silicone oil in a mass ratio of 4:1. The organosilicon crosslinking agent is ethyl orthosilicate. The long-chain alkylsilane is dodecyltriethoxysilane. The organosilicon quaternary ammonium salt is diethoxymethylsilylpropyl octadecyldimethylammonium ...

Embodiment 2

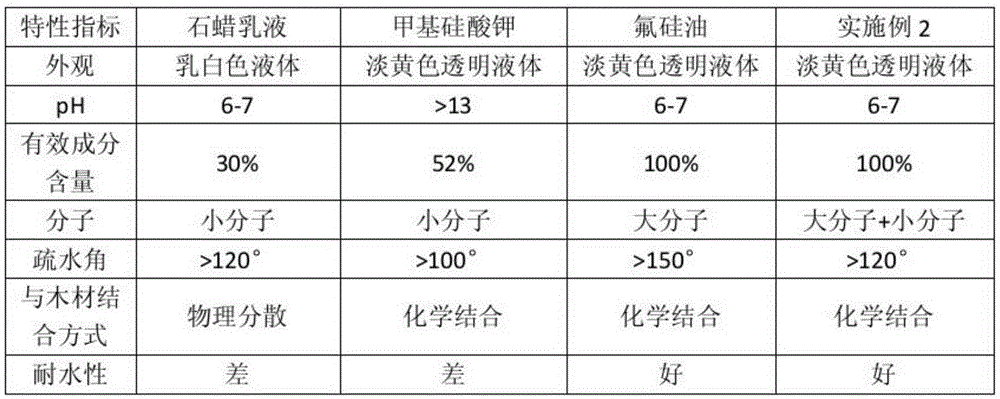

[0033] A high-efficiency penetrating silicone water repellant for wood is prepared from the following raw materials: 40% of silicone resin prepolymer, 35% of a mixture of hydroxysilicone oil and dimethyl silicone oil, 10% of silicone crosslinking agent, and long-chain alkyl silane 5%, organosilicon quaternary ammonium salt 1%, pH adjusting organic solution 2%, auxiliary agent 2%, nanofiller 5%; the silicone resin prepolymer is propyl and octyl silicone resin copolymer, propyl silicone resin The mass ratio to octyl silicone resin is 2:1, and the percentages are all mass percentages. The mixture of hydroxy silicone oil and dimethyl silicone oil is a mixture of 50,000-viscosity hydroxy-silicone oil and 60,000-viscosity dimethyl silicone oil in a mass ratio of 4:1. The organosilicon crosslinking agent is ethyl orthosilicate. The long-chain alkylsilane is dodecyltriethoxysilane. The organosilicon quaternary ammonium salt is diethoxymethylsilylpropyl octadecyldimethylammonium chlo...

Embodiment 3

[0038] A high-efficiency penetrating silicone water repellant for wood, prepared from the following raw materials: 33% silicone resin prepolymer, 37% mixture of hydroxy silicone oil and dimethyl silicone oil, 8% silicone crosslinking agent, long-chain alkyl silane 7%, organosilicon quaternary ammonium salt 1.5%, pH adjusting organic solution 1.5%, auxiliary agent 8%, nanofiller 4%; the silicone resin prepolymer is propyl and octyl silicone resin copolymer, propyl silicone resin The mass ratio to octyl silicone resin is 2:1, and the percentages are all mass percentages. The mixture of hydroxy silicone oil and dimethyl silicone oil is a mixture of 50,000-viscosity hydroxy-silicone oil and 60,000-viscosity dimethyl silicone oil in a mass ratio of 4:1. The organosilicon crosslinking agent is ethyl orthosilicate. The long-chain alkylsilane is dodecyltriethoxysilane. The organosilicon quaternary ammonium salt is diethoxymethylsilylpropyl octadecyldimethylammonium chloride. The pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com