Hydrotalcite used in polymer and preparation method thereof

A hydrotalcite and polymer technology, applied in the direction of zinc compounds, aluminum compounds, chemical instruments and methods, etc., can solve problems such as unsatisfactory effects, and achieve good light stability, good compatibility, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

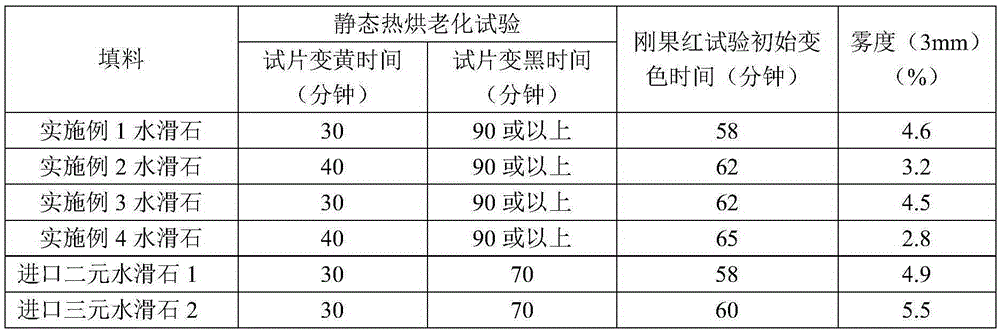

Examples

Embodiment 1

[0029] Example 1: Mg 4 Al 2 (OH) 12 CO 3 4H 2 Preparation of O

[0030] 0.5 mol of Mg(HCO 3 )2 , 2 mol NaAlO 2 , 1 MgCl 2 , 2.5 moles of Mg(OH) 2 and 7.0 moles of H 2 O mixed, fully stirred, heated to 78 ° C ± 1, and kept stirring for 3 hours to obtain the hydrotalcite product 1.

[0031] The hydrotalcite product 1 was characterized by XRD, NMR, FT-IR and XPS to verify the structure of the hydrotalcite product 1, which is Mg 4 al 2 (OH) 12 CO 3 4H 2 O.

Embodiment 2

[0032] Example 2: Mg 3.35 Zn 0.65 al 2 (OH) 12 CO 3 4H 2 Preparation of O

[0033] 0.5 mol of Mg(HCO 3 ) 2 , 2 mol NaAlO 2 , 0.65 mol ZnCl 2 and 0.35 molar MgCl 2 , 2.5 moles of Mg(OH) 2 and 7.0 moles of H 2 O mixed, fully stirred, heated to 82 ° C ± 1, and kept stirring for 3.5 hours to obtain the hydrotalcite product 2.

[0034] The hydrotalcite product 2 was characterized by XRD, NMR, FT-IR and XPS to verify the structure of the hydrotalcite product 2, which is Mg 3.35 Zn 0.65 al 2 (OH) 12 CO 3 4H 2 O.

Embodiment 3

[0035] Example 3: Mg 5 al 2.5 (OH) 15 (CO 3 ) 1.25 4H 2 Preparation of O

[0036] 0.625 moles of Mg(HCO 3 ) 2 , 2.5 mol NaAlO 2 , 1.25 mol MgCl 2 , 3.125 moles of Mg(OH) 2 and 7.75 moles of H 2 O mixed, fully stirred, heated to 78 ° C ± 1, and kept stirring for 3 hours to obtain the hydrotalcite product 3.

[0037] The hydrotalcite product 3 was characterized by XRD, NMR, FT-IR and XPS to verify the structure of the hydrotalcite product 3, which is Mg 5 al 2.5 (OH) 15 (CO 3 ) 1.25 4H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com