Equipment and method for detecting weld joints of turbine components

A welding seam detection and component technology, which is applied in the field of turbine component welding seam detection equipment and detection, can solve the problems of long detection time that cannot be used in industrial production, low artificial detection accuracy, easy to miss inspection parts, etc., to achieve rapid detection and not easy Leak detection, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

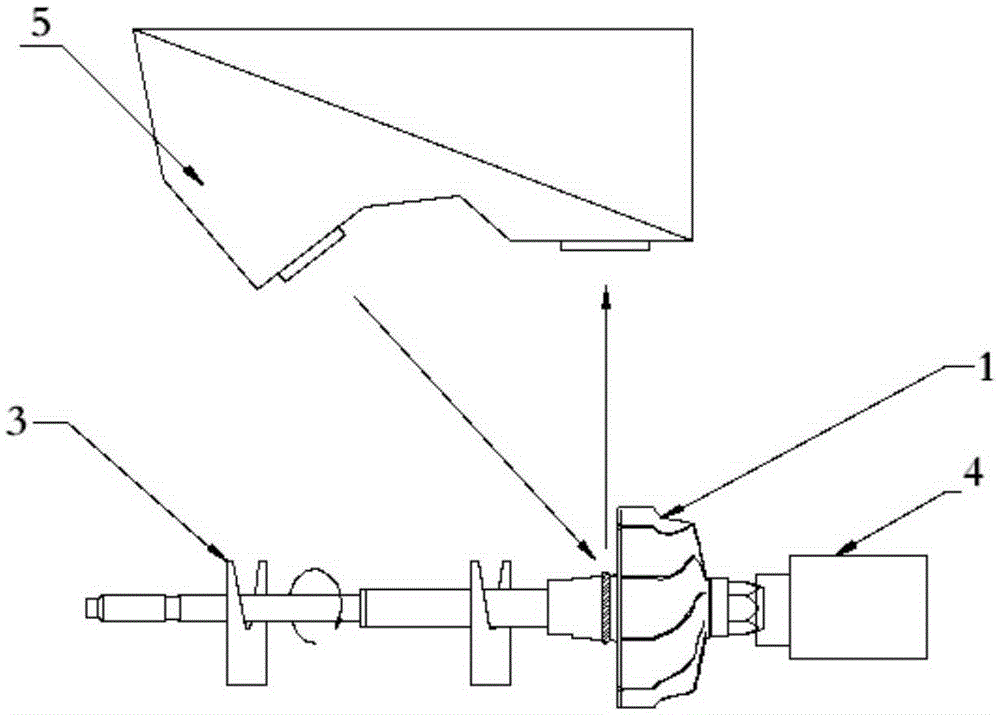

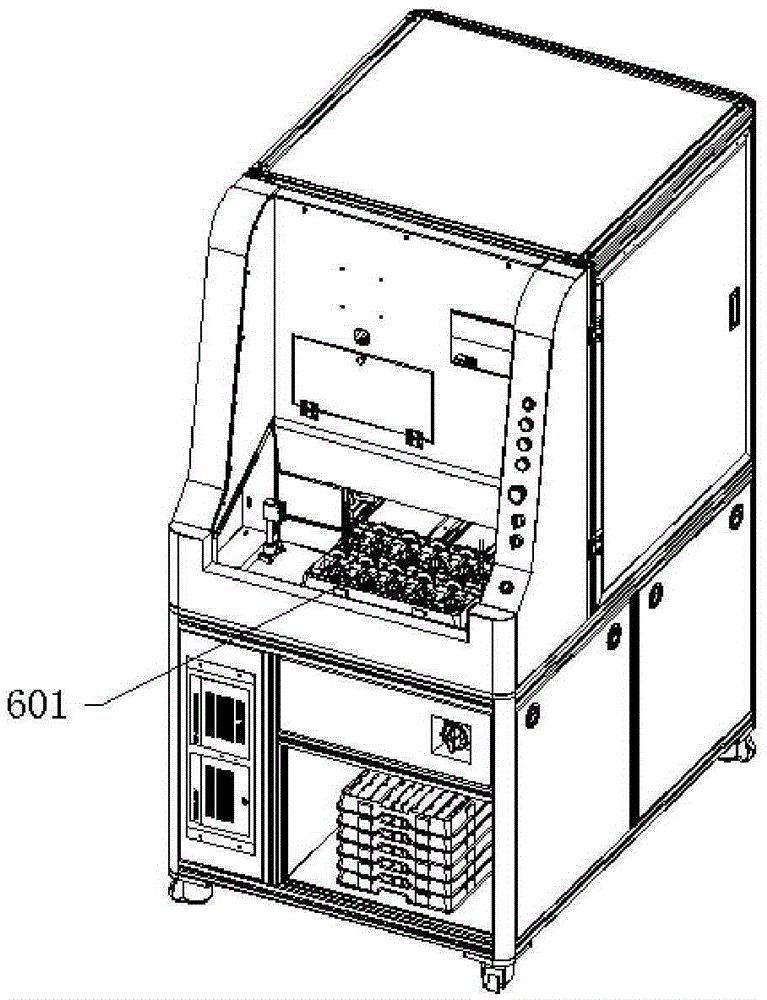

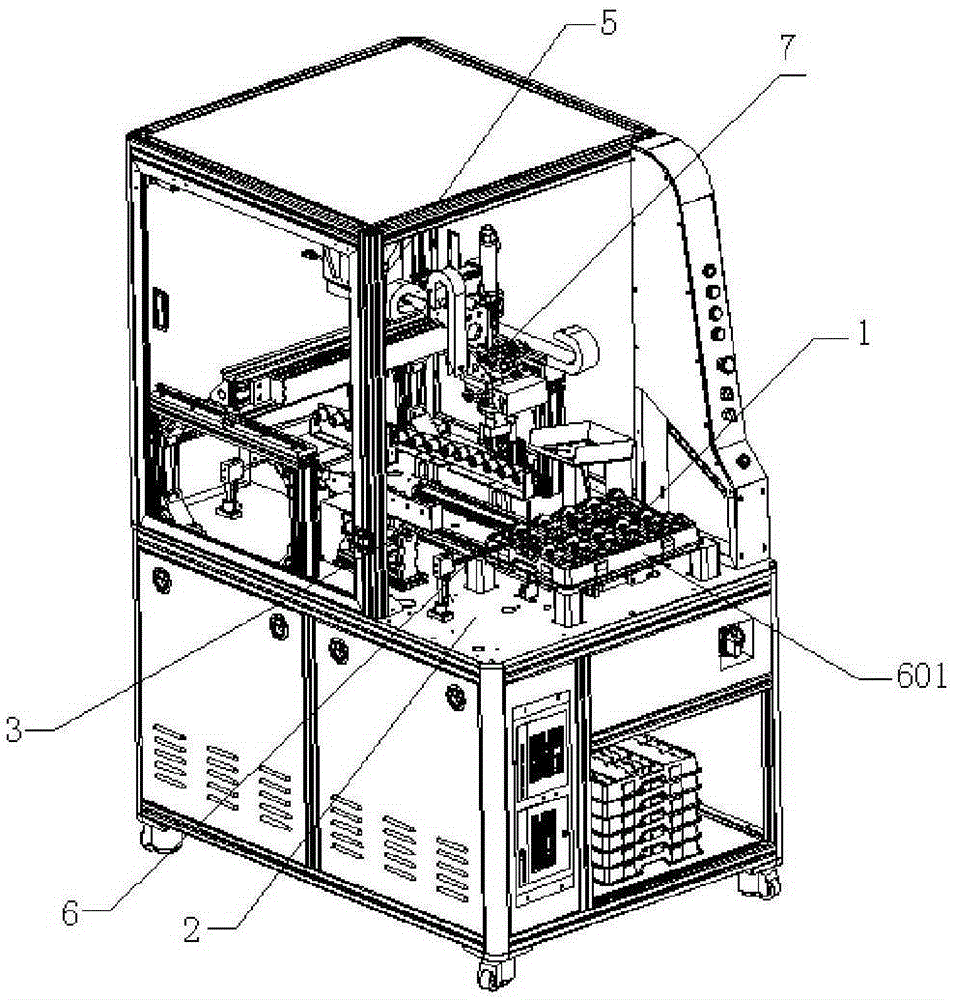

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a turbine component welding seam inspection equipment includes a positioning tool 3, a rotary drive mechanism 4 and at least one 3D laser scanning camera 5, the turbine component 1 to be detected can be rotatably positioned on the positioning tool, and the rotary drive mechanism The axis of the turbine component to be detected can be used as the axis to drive it to rotate at a certain speed; the rotation drive mechanism feeds back the rotation signal to the 3D laser scanning camera through computer software; the 3D laser scanning camera is set at the Detect around the turbine component, make the lens of the 3D laser scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com