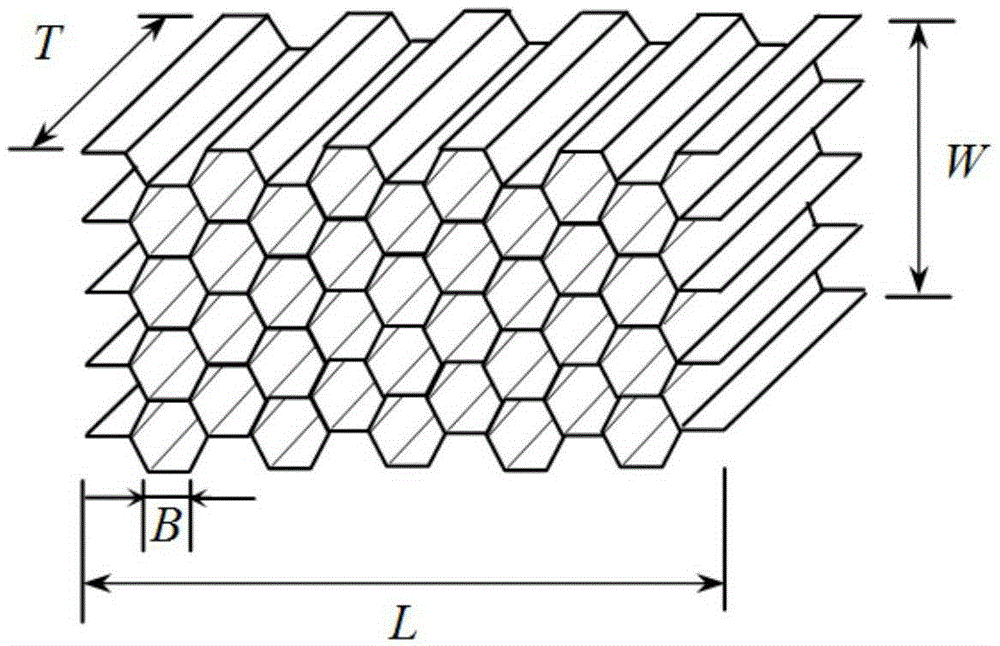

Thin slab layer for formation of honeycomb structure, honeycomb structure and preparation method thereof

A technology of honeycomb structure and thin plate is applied in the field of honeycomb structure and its preparation, forming thin plate layer of honeycomb structure, which can solve problems such as loss of weight loss, and achieve the effect of reducing the compression amount of honeycomb structure, accurate shape and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

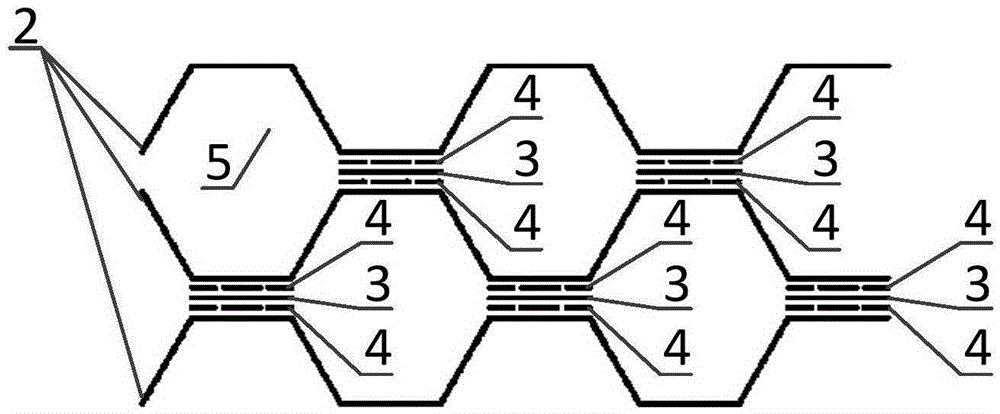

[0095] Further preferably, this embodiment provides a method for preparing the sheet layer 1, wherein the method for preparing includes the following steps:

[0096] (1) The reinforcement layer 3 includes an upper surface and a lower surface, and an adhesive 4 is provided on the upper surface and the lower surface of the reinforcement layer 3. The reinforcement layer 3 is a reinforcing material or a functional material, and each reinforcement layer 3 is in the width direction. The width of is set to 1 cell wall width;

[0097] (2) At least three layers of sheet material 2 are arranged vertically from top to bottom;

[0098] (3) at least two strengthening layers 3 in step (1) are arranged between the adjacent sheet materials 2 in step (2); each adjacent strengthening layer 3 in step (1) on the same horizontal plane The spacing in the width direction is all set to 3 unit wall widths; the spacing in the width direction of the strengthening layer 3 in each step (1) adjacent to th...

Embodiment 1

[0102] A preparation method of a novel aramid paper honeycomb structure 5 sheet layer 1 and aramid paper honeycomb core material:

[0103] The materials and process conditions used are:

[0104] Thin plate material 2 is aramid paper of DuPont Company T412 type specification of 4mil;

[0105] The reinforcing material is a cured single-layer T300 / QY9916-2 non-dimensional cloth.

[0106] The adhesive 4 on the thin plate material 2 and the reinforcing material is coated with a T450-1 laboratory gravure coating machine; the width of the adhesive 4 is 5 mm, and the distance between the adhesive 4 is 15 mm;

[0107] Adhesive 4 is the J-80B Nomex paper honeycomb sandwich adhesive developed by Heilongjiang Petrochemical Research Institute;

[0108] The resin is barium phenolic resin, produced by Beijing FRP Research Institute.

[0109] The preparation method comprises the following steps:

[0110] (1) The reinforcement layer 3 includes an upper surface and a lower surface, and an a...

Embodiment 2

[0130] A preparation method of a novel aramid paper honeycomb structure 5 sheet layer 1 and aramid paper honeycomb core material:

[0131] The materials and process conditions used are:

[0132] Sheet material 2 is 1414-type aramid paper with a specification of 2mil by Yantai Taihe New Materials Co., Ltd.;

[0133] The functional material is T700 / 5228E non-dimensional cloth with cured single-layer ferrite absorbing agent;

[0134] Adhesive 4 on the sheet material 2 is coated using a T450-1 laboratory gravure coater, the width of the adhesive 4 is 5 mm, and the distance between the adhesive 4 is 15 mm; the adhesive on the functional material Agent 4 is painted by hand, and then the functional material is cut into 5mm wide strips.

[0135] Adhesive 4 is the J-80B Nomex paper honeycomb sandwich adhesive developed by Heilongjiang Petrochemical Research Institute;

[0136] The resin is phenolic resin, produced by Nantong Sumitomo Bakelite Co., Ltd.

[0137] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com