Suit door glue sprayer

A technology of glue spraying machine and suit door, which is applied in the field of wood surface, which can solve the problems of reducing glue viscosity, reducing glue effect, and bristles falling into the wooden board, so as to ensure the sticking effect, improve stickiness, and prevent hair loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

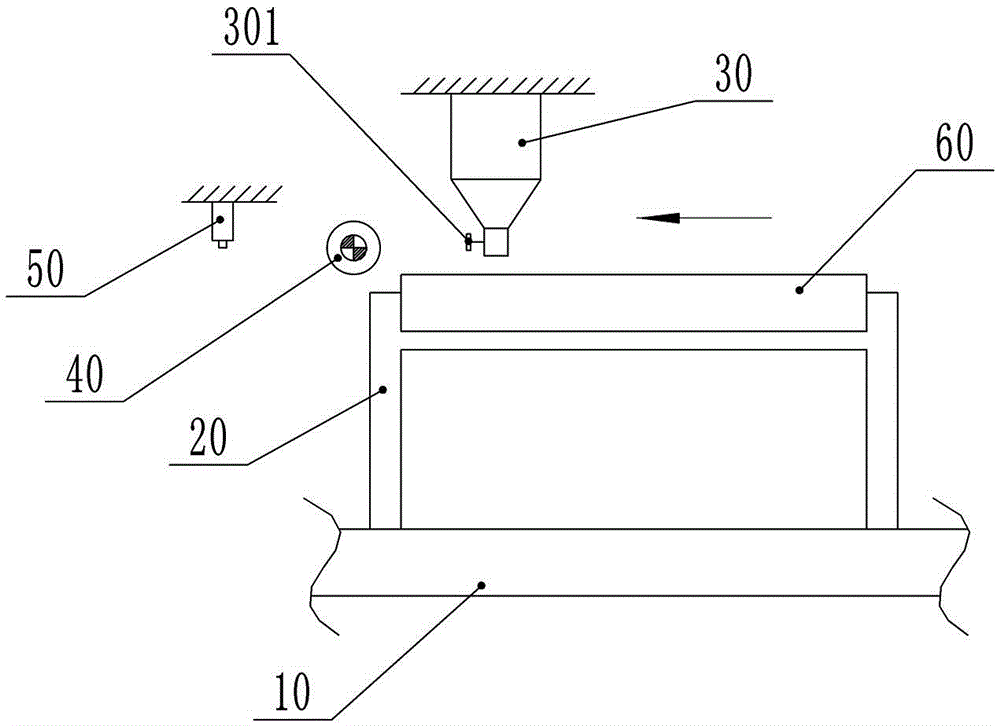

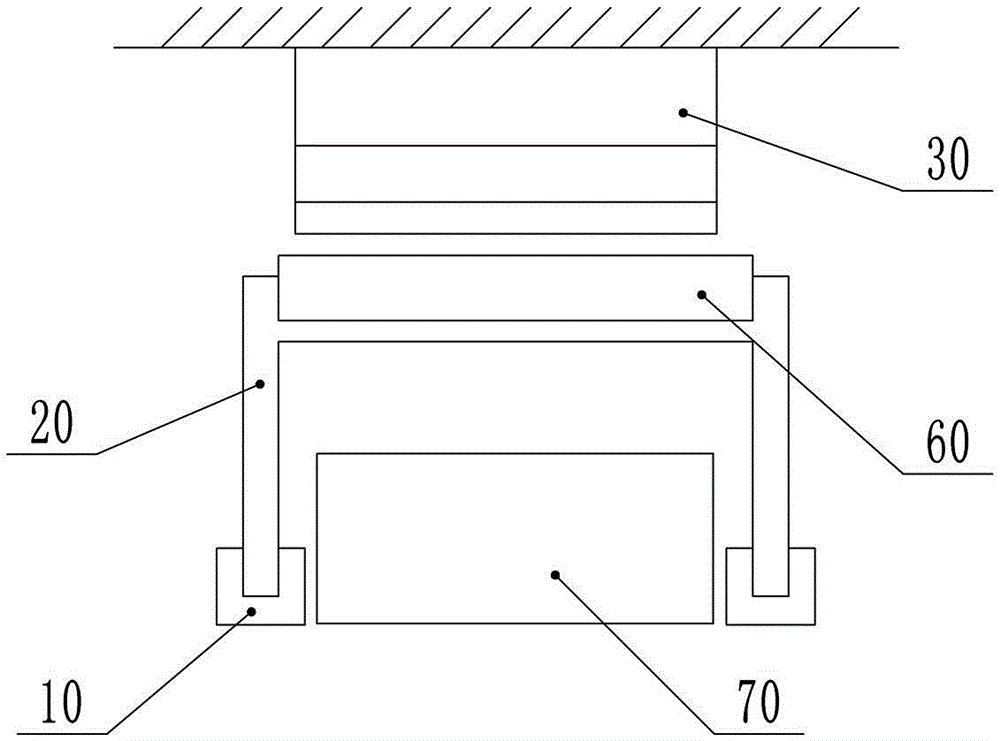

[0015] The reference signs in the drawings of the description include: slide rail 10 , fixing device 20 , discharge box 30 , valve 301 , pressure roller 40 , spray head 50 , plank 60 , and collection box 70 .

[0016] Such as figure 1 , figure 2 As mentioned above, the set door glue spraying machine includes a frame, a fixing mechanism for fixing the plank 60 , a pressing roller 40 , a discharge box 30 , a nozzle and a slide rail 10 . The fixing mechanism is provided with a groove for accommodating the plank 60 , the plank 60 is put into the groove, and a wedge block is inserted to fix the plank 60 . The fixing mechanism is slidably connected with the slide rail 10 . The pressure roller 40, the discharge box 30 and the nozzle are all installed above the fixing mechanism. The pressure roller 40 is located between the nozzle and the discharge box 30 , the nozzle is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com