Method for improving fatigue performance of steel plate and butt-welded joint

A technology for welding joints and fatigue performance, applied in the field of material surface strengthening, can solve the problems of single metal surface strengthening process and low degree of strengthening, and achieve the effect of increasing the bonding effect, reducing the degumming and improving the fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

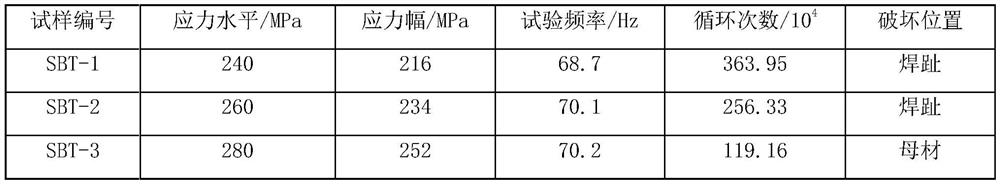

Embodiment 1

[0061] The CFRP material is CFRP cloth.

[0062] A method for improving the fatigue performance of steel plates and butt welded joints, the steps of which are:

[0063] Step A, ultrasonic shock treatment

[0064] Step A1, using an impact head to perform two impact treatments on the weld toe;

[0065] Step A11, using three rows of cylindrical impact heads with a diameter of 2 mm to perform the first impact treatment on the welding toe, and the speed is controlled at 60 mm / min;

[0066] Step A12, after the first impact treatment is completed, use a single row of cylindrical impact heads with a diameter of 5 mm to perform a second impact treatment on the welding toe, and the speed is controlled at 60 mm / min;

[0067] Step A13. Finally, use a sheet-shaped impact head to perform full-coverage impact treatment on the weld seam, and the speed is controlled at 30mm / min;

[0068] Step A2, finally using the impact head to impact the full coverage of the weld seam;

[0069] Step B, C...

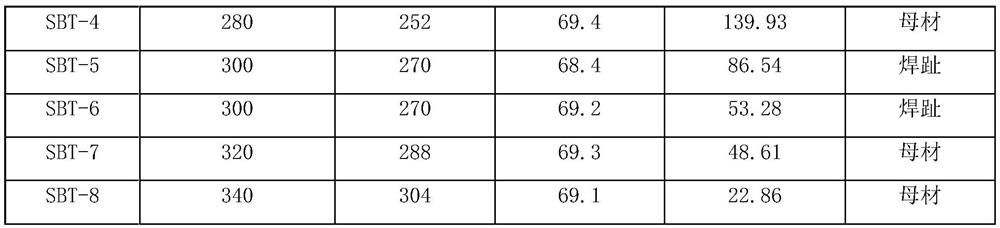

Embodiment 2

[0081] A method for improving the fatigue performance of steel plates and butt welded joints, the steps of which are:

[0082] Step A, ultrasonic shock treatment

[0083] Step A1, using an impact head to perform three impact treatments on the weld toe;

[0084] Step A11, using three rows of cylindrical impact heads with a diameter of 3 mm to perform the first impact treatment on the welding toe, and the speed is controlled at 70 mm / min;

[0085] Step A12, after the first impact treatment is completed, use a single row of cylindrical impact heads with a diameter of 7 mm to perform a second impact treatment on the welding toe, and the speed is controlled at 70 mm / min;

[0086] Step A13, after the second impact treatment is completed, use a single row of cylindrical impact heads with a diameter of 7mm to perform the third impact treatment on the unsmooth part of the welding toe, and the speed is controlled at 70mm / min;

[0087] Step A14. Finally, use a sheet-shaped impact head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com