A tape vacuum pasting mechanism

A vacuum and tape technology, applied in the field of auxiliary equipment, can solve the problems of increasing the scrap rate, affecting the product quality, and the tape effect is not very good, and achieving the effect of tight integration and improving the sticking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

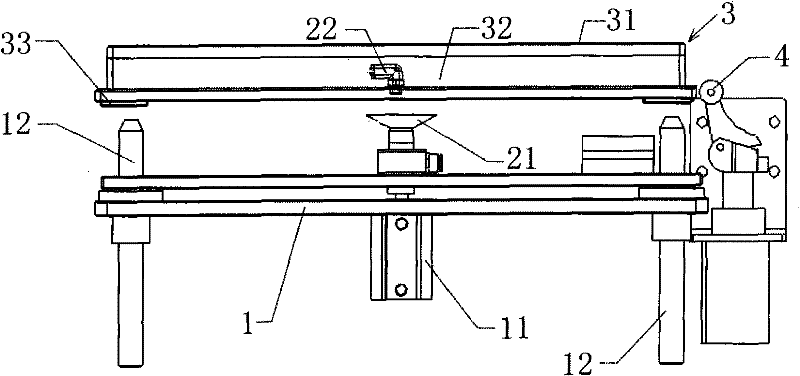

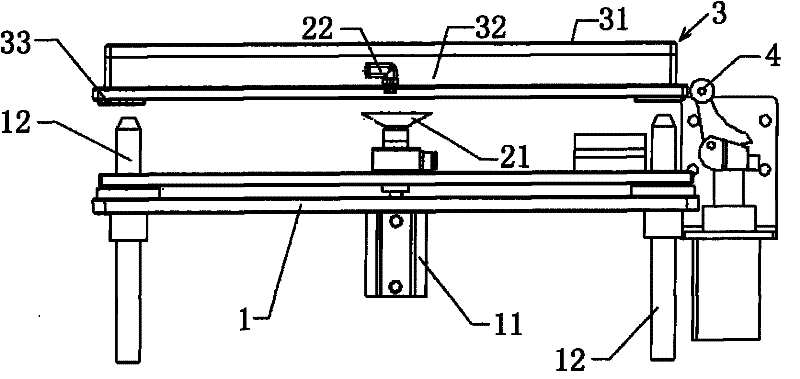

[0017] Such as figure 1 The tape vacuum sticking mechanism shown is a set of mechanisms for sticking tape on the film. The tape is fixed in the form of vacuum adsorption when sticking. Since the tape and film move with the line body / conveyor belt, Therefore, it is necessary to have such a vacuum mechanism at each station to position the film product. The specific implementation is as follows:

[0018] When the transfer tray 3 uses the upper bearing surface 31 to move the film product to each pasting station, the blocking cylinder 4 drives a limit stopper to extend to the side where the tray 3 advances along the conveyor belt to block the tray, and the lifting cylinder 11 rises The positioning pins 12 on both sides of the lifting arm 1 are inserted into the positioning pin holes 33 at the bottom of the tray to lift up the tray 3 together with the film products placed on the carrying surface 31, and at this moment the vacuum nozzle 21 set in the middle of the lifting arm 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com