A kind of nano palladium immobilized filter paper and its preparation and application

A nano-palladium and filter paper technology, which is applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, chemical instruments and methods, etc., can solve the problems of complex preparation process of palladium nanoparticles, harsh preparation conditions, environmental pollution, etc., and achieves improved reuse. Performance, preparation method is simple, stable and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

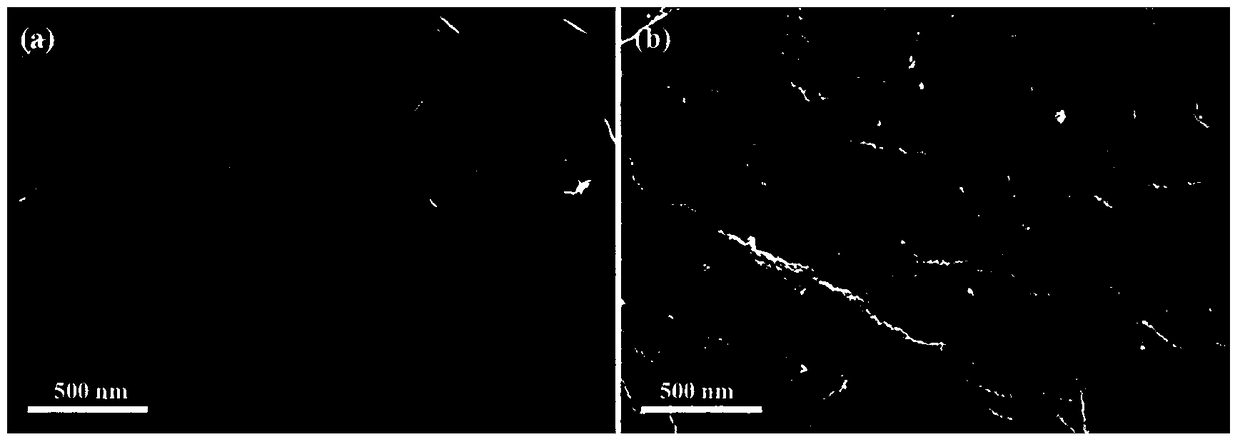

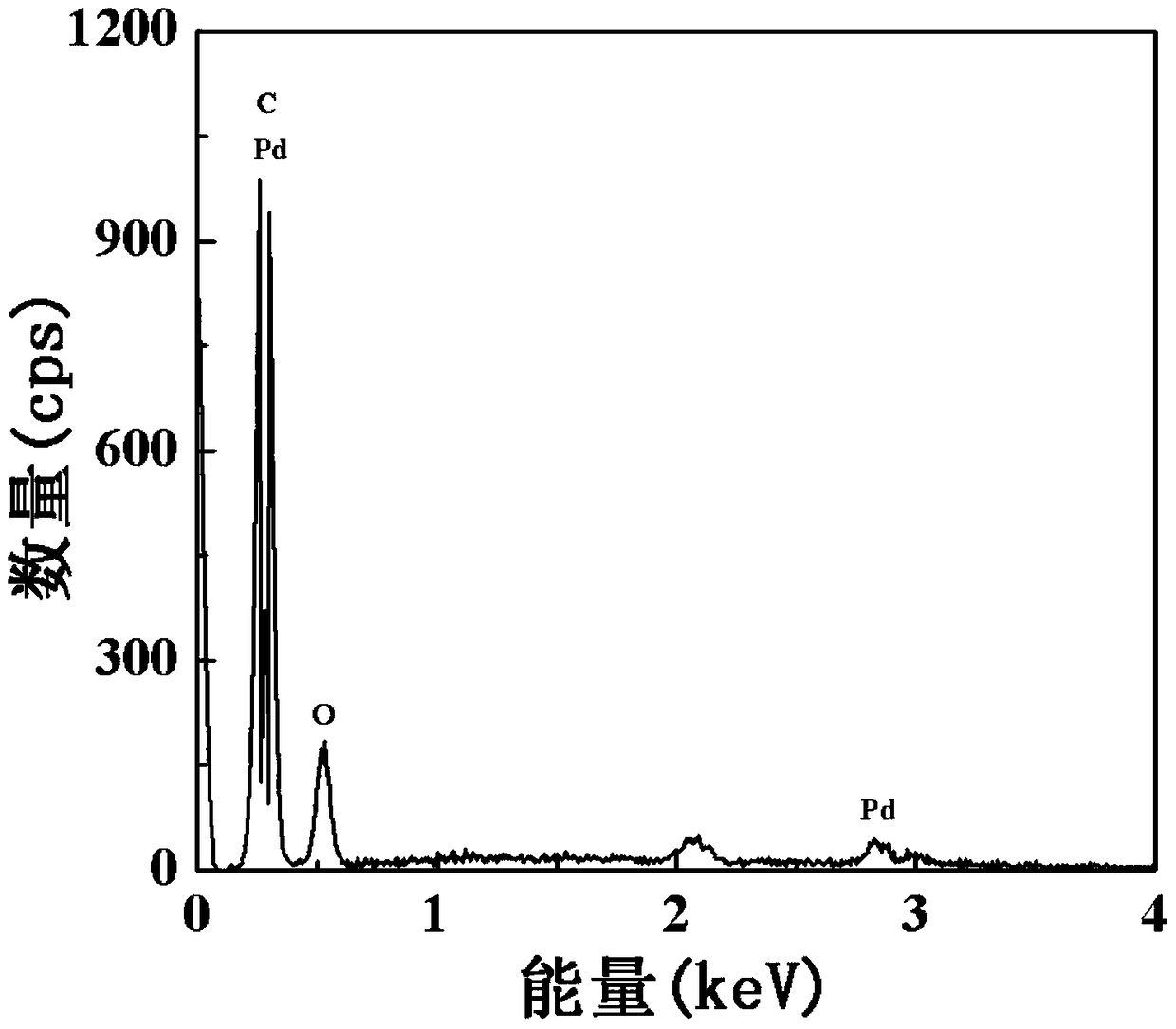

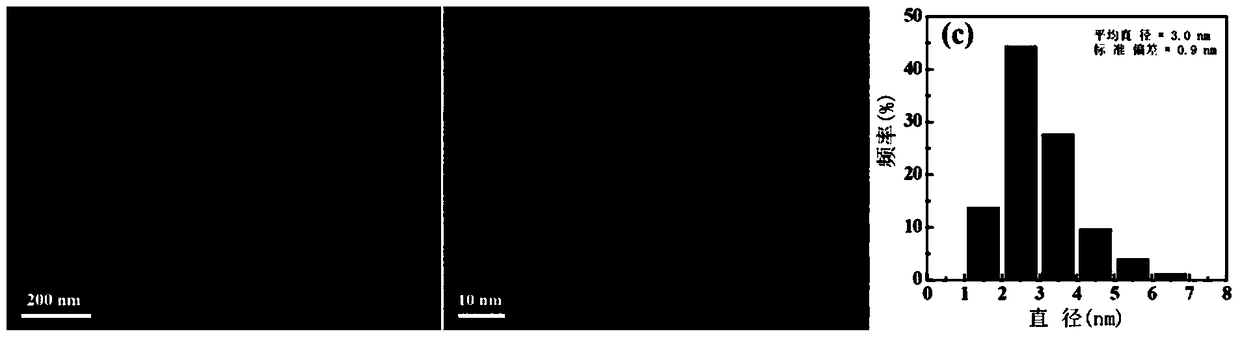

[0045] Dissolve 100 mg of polyethyleneimine in 5 mL of distilled water to prepare a 20 mg / mL polyethyleneimine aqueous solution. Dissolve 65 mg of potassium tetrachloropalladate in 5 mL of distilled water to prepare a 13 mg / mL potassium tetrachloropalladate aqueous solution. Dissolve 40 mg of sodium borohydride in 5 mL of distilled water to prepare an 8 mg / mL aqueous solution of sodium borohydride for use. Soak the dry ordinary filter paper in the polyethyleneimine aqueous solution prepared above, wash off the polyethyleneimine that is not adsorbed on the surface of the filter paper with distilled water after 5 minutes, and then soak it in the potassium tetrachloropalladate solution. Wash with water after 5 minutes, and finally soak the washed filter paper in sodium borohydride aqueous solution, wash with water after 10 minutes, and dry it in vacuum for 24 hours to obtain nano-palladium-immobilized filter paper. Using SEM to observe the morphology of nano-palladium immobilize...

Embodiment 2

[0047] Add 88.26mg of potassium dichromate and 100mL of water into a beaker and stir it magnetically to prepare a 3mM potassium dichromate solution for use. 10 mL of 3mM potassium dichromate solution, 1.5 mL of formic acid solution and 15 mL of deionized water were mixed and stirred evenly, and 20 mg of solid-supported palladium nanoparticle filter paper was soaked in the mixed solution. Under the condition of magnetic stirring, the catalysis experiment of potassium dichromate reduction reaction was carried out by using the prepared material. At each catalytic time point of 0min, 4min, 8min, 12min, 16min, 20min, 24min and 28min, 0.5mL of the reaction solution was diluted to 1mL to measure the concentration of Cr(VI) in the solution. The UV-vis test results showed that the absorption peak (350nm) of Cr(VI) decreased rapidly with the increase of reaction time. Be 28min in reaction time, corresponding catalytic efficiency just can reach 98% (as Figure 5 ). The catalytic exper...

Embodiment 3

[0049] First take 13.91mg of 4-nitrophenol and add it to 10mL of aqueous solution with magnetic stirring to prepare a 10mM light yellow 4-nitrophenol solution, then take 378.3mg of sodium borohydride and dissolve it in 1mL of ice water solution for use. Take 0.6mL 10mM 4-nitrophenol solution, 0.6mL 10M NaBH 4 The solution was mixed with 16.8 mL of deionized water and stirred evenly, and 20 mg of nanometer palladium-immobilized filter paper was soaked in the mixed solution. Catalytic experiments were performed on 4-nitrophenol using the prepared material under magnetic stirring. At each catalytic time point of 0min, 1min, 2min, 3min, 4min, 6min, 8min, 12min, 20min, 28min and 36min, take 0.5mL reaction solution and dilute it to 1.5mL to measure the concentration of 4-nitrophenol in the solution . The UV-vis test results showed that: with the increase of reaction time, the absorption peak (400nm) of 4-nitrophenol decreased rapidly, while the characteristic peak (300nm) of 4-ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com