Method for preparing melem capable of degrading various dyes

A melem, degradable technology, applied in the field of photocatalytic materials and their preparation, can solve the problems of complicated reaction operation process and long cycle, and achieve the effect of shortening the preparation cycle, easy operation and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 The following steps were used to prepare melem: 2.5 g of melamine was weighed into a corundum ark, covered, and the corundum ark was placed in a closed tube furnace. Vacuumize, return to normal pressure with argon gas, argon flow rate is 50sccm, sintering temperature is 400-450°C, heating and cooling rate is 10°C / min, holding time is 2 hours, and the product is ground and collected.

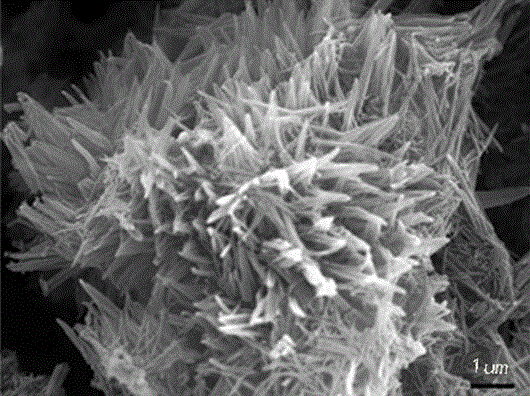

[0025] The X-ray diffraction pattern analysis result of gained product shows that it is the melem of hexagonal crystal system, as figure 1 shown. Scanning electron microscopy shows microscopically that this process prepares melem nanowire bundles, such as figure 2 shown.

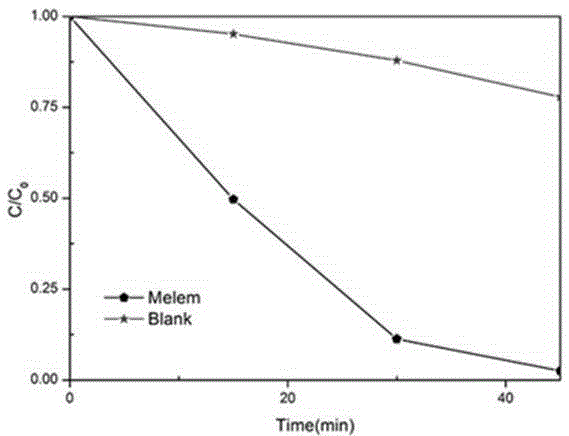

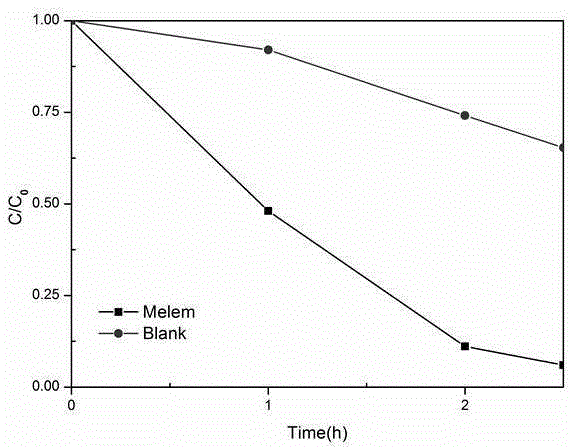

[0026] Taking rhodamine B as an example, the application experiment of the melem catalyzed degradation dye prepared by this embodiment is described as follows: take 20 mg of melem, add it to a test tube containing 40 ml of rhodamine B at a concentration of 20 ppm, and stir it in the dark After 40 minutes to...

Embodiment 2

[0029] Example 2 Weigh 1 g of melamine and put it into a corundum ark, cover it, and place the corundum ark in a closed tube furnace. Vacuumize, return to normal pressure with argon gas, the argon flow rate is 50 sccm, the sintering temperature is 500°C, the heating and cooling rate is 10°C / min, the holding time is 2 hours, and the product is ground and collected.

Embodiment 3

[0030] Example 3 Weigh 3 g of melamine and put it into a corundum ark, cover it, and place the corundum ark in a closed tube furnace. Vacuumize, return to normal pressure with argon gas, the argon flow rate is 40 sccm, the sintering temperature is 400-450°C, the heating and cooling rate is 10°C / min, and the holding time is 5 hours. The product is ground and collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com