Dust removing system for wood-plastic pelletizer

A technology of dust removal system and granulator, which is applied in the separation of dispersed particles, filtration of dispersed particles, chemical instruments and methods, etc., can solve problems such as polluted workshops, and achieve the effect of prolonging service life, improving dust removal effect and reducing dust removal cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

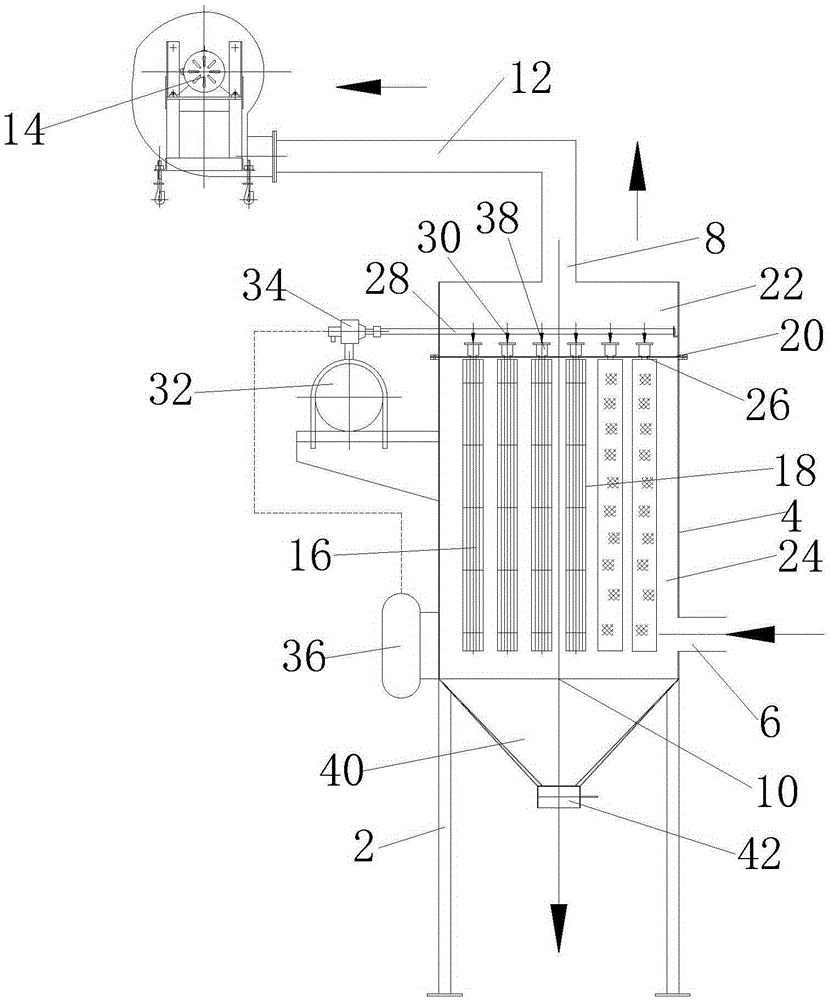

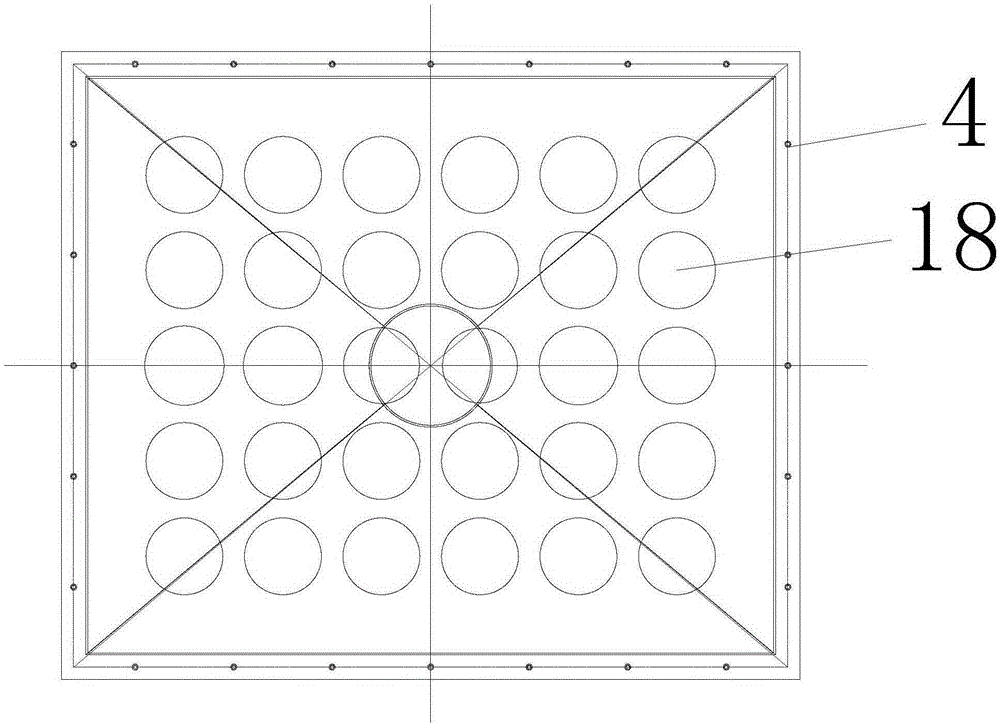

[0020] Such as figure 1 , 2 As shown, a dust removal system for a wood pelletizer is disclosed in this embodiment, comprising a frame 2 and a dust removal box 4 fixed thereon, the lower half of the dust removal box 4 being positioned at its side is provided with Dust air inlet 6, the top and bottom of the dust removal box 4 are respectively provided with a clean air outlet 8 and a dust outlet 10, and one end is connected to the clean air outlet 8 with a suction pipe 12, and the suction pipe The other end of 12 is connected to a suction device 14. Several keel frames 16 arranged in parallel are arranged in the dust removal box 4, and the keel frames 16 extend along the line connecting the clean air outlet 8 and the dust outlet 10. Each of the keel frames 16 is sheathed with a dust filter bag 18, and in the present invention, the cross section of the dust filter bag 18 is preferably circular.

[0021] The gas mixed with dust enters the dust removal box 4 from the dust gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com