Semi-solid emulsification seasoning and preparation method thereof

A semi-solid and seasoning technology, which is applied in the field of food processing, can solve the problems of not involving the emulsification state of acidic oil-in-water emulsified food, not involving the freezing resistance of semi-solid seasoning, and the taste is not rough, etc., to achieve excellent freezing resistance and freeze-thaw stability, improve freeze-thaw resistance and freeze-thaw stability, and alleviate the effect of moisture migration

Inactive Publication Date: 2016-02-03

GUANGZHOU HAODAO FOOD CO LTD

View PDF6 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Chinese patent CN201280059858.4 discloses a freeze-resistant acidic protein food that does not cause dehydration after freezing and thawing, has a non-rough taste, and maintains smoothness before freezing. By adding oligosaccharides, polysaccharides and gelling agents to inhibit protein aggregation during thawing , so as to inhibit dehydration and pore generation, but it mainly solves the problem of dehydration and rough taste after freezing and thawing of acidic protein foods represented by yogurt, and the frozen storage time at -18°C involved in this patent is only one week, and Freezing resistance of semi-solid condiments made by emulsification without adding liquid oil

[0005] Chinese patent CN201180031962.8 discloses a freeze-resistant acidic oil-in-water emulsified food that also has a stable emulsified state after thawing. Starch is dispersed in the acidic oil-in-water emulsified food with a specific particle size in a non-dissolved state. The water phase of food, however, this patent requires special treatment and screening of starch, and control of the particle size of oil droplets and starch to achieve the desired effect, and does not involve the emulsification state of acidic oil-in-water emulsified food after repeated freezing and thawing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

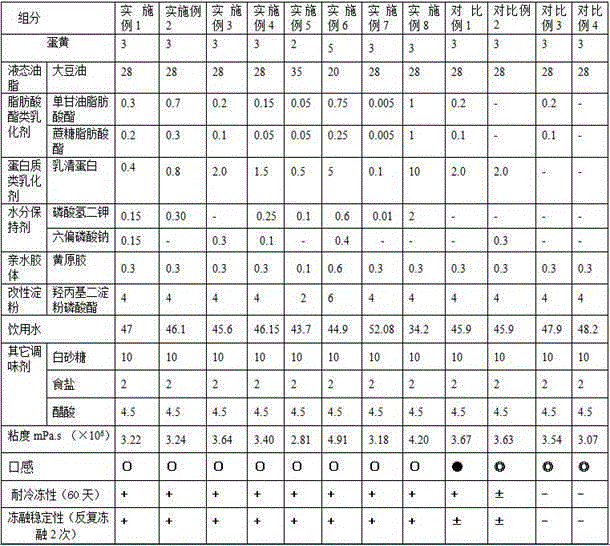

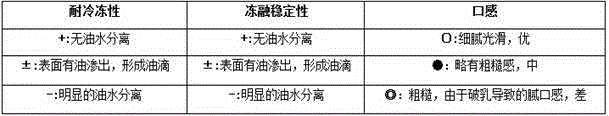

Embodiment 1-8 and comparative example 1-4

[0060] Embodiment 1-8 and comparative example 1-4: the preparation of semi-solid emulsified seasoning

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a semi-solid emulsification seasoning. The semi-solid emulsification seasoning comprises the following components in parts by weight: 1-10 parts of yolk, 5-45 parts of liquid grease, 0.01-2 parts of fatty acid ester emulsifier, 0.1-10 parts of protein emulsifier, 0.01-2 parts of water retention agent, 0.1-10 parts of modified starch, 0.01-5 parts of hydrophilic colloid and 44-66 parts of drinking water. In the invention, the semi-solid emulsification seasoning is prepared by adding certain amount of the fatty acid ester emulsifier and the protein emulsifier and adding certain amount of the water retention agent in a traditional semi-solid emulsification seasoning with salad dressing as a representative, and even after being frozen and thawed, the prepared semi-solid emulsification seasoning still keeps excellent freezing resistance and freeze-thaw stability. In addition, various raw materials are added according to an appropriate mixing ratio, the synergistic effect of each raw material is integrated, special treatment is not needed in the preparation process of the semi-solid emulsification seasoning or the raw materials and auxiliary materials, and the preparation method can be accomplished by adopting a common making process, therefore, the production efficiency is greatly improved.

Description

technical field [0001] The invention relates to the technical field of food processing, in particular to a semi-solid emulsified seasoning with freeze resistance and freeze-thaw stability and a preparation method thereof. Background technique [0002] In recent years, semi-solid emulsified seasonings represented by salad dressings have been widely used in the baking and catering markets and become a part of daily diet. With the expansion of its use, on the one hand, it is hoped to be used in quick-frozen baked goods, and on the other hand, it can solve the difficulties of transportation and storage in the cold northern regions. For families, it is hoped that the remaining semi-solid emulsified seasoning will be frozen and stored until It can still maintain its original emulsified state when it is thawed again for use. However, during the freezing process of ordinary semi-solid emulsified seasonings, especially during long-term freezing, the egg yolk phospholipid protein wit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23L27/20

Inventor 石振兴宁宗峰郑潮鹏

Owner GUANGZHOU HAODAO FOOD CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com