Autoclaved sand-lime brick and production technology

A technology of autoclaved lime-sand bricks and production process, which can be applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Good freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] refer to figure 1 ,Such as figure 1 An autoclaved lime-sand brick of the present invention is shown, consisting of 20%-35% of sea oyster shell powder, 30%-45% of construction waste, 20%-35% of sand, and 10%-15% of lime , made of 10%--15% stone powder.

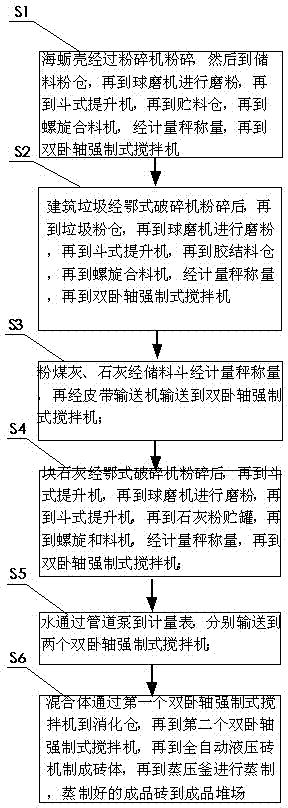

[0026] figure 2 Shown is a kind of autoclaved lime-sand brick production process of the present invention, comprises the following steps:

[0027] S1, sea oyster shells are pulverized by a pulverizer, then go to the storage powder bin, then go to the ball mill for grinding, then go to the bucket elevator, then go to the storage bin, and then go to the screw mixer, and then weighed by the weighing scale. Then to the twin-shaft forced mixer;

[0028] S2. After the construction waste is crushed by the jaw crusher, it goes to the garbage powder bin, then to the ball mill for grinding, then to the bucket elevator, then to the cement bin, and then to the screw mixer, and then weighed by the weighing scale. , and then to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com