Coatings for controlled release of highly water soluble drugs

A technology for water-soluble drugs and drugs, applied in drug delivery, antibacterial drugs, pharmaceutical formulations, etc., can solve problems such as abrasions, ruptures, and difficulties in designing stable trapping or enveloping coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

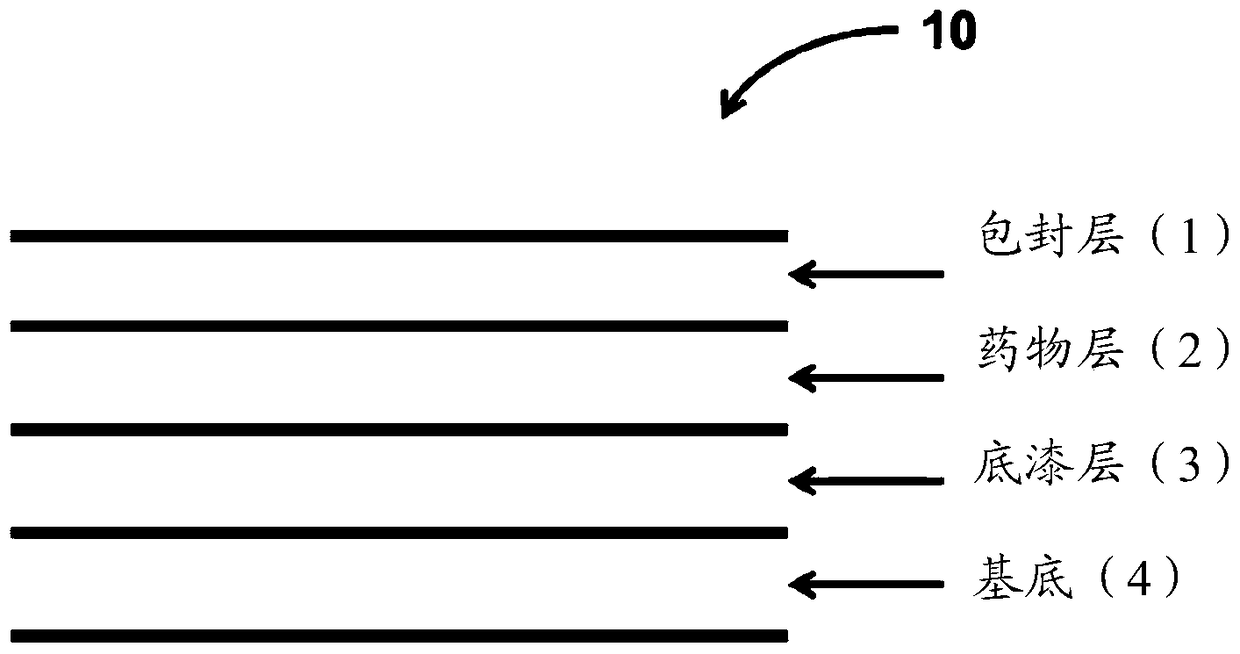

Method used

Image

Examples

example 1

[0108] Example 1. General Coating Procedure

[0109] A. Primer layer:

[0110] Silicone catheters (0.5 mm outer diameter) were dip-coated with a 30 mg / ml Photo-POMAS solution in isopropanol. Initially, clean the silicone rubber by rubbing it with isopropyl alcohol six times with a lint-free cloth. Then, the catheter was inserted into the coating solution at a rate of 2 cm / sec, left in the solution for 30 seconds, and withdrawn from the coating solution at 0.5 cm / sec. The primer coat was air dried at room temperature for 10 minutes and then UV irradiated with 254 nm light (40 mW / cm2) for one minute.

[0111] B. Silver nitrate layer:

[0112] An aqueous solution of silver nitrate was prepared by dissolving 20 grams of silver nitrate (USP grade, 99.8-100.2%, Sigma Aldrich, St. Louis, MO) in 10 ml of distilled water. This silver nitrate solution was sprayed onto the primer coat with a low volume, low pressure EFD 7856-46SS spray head (Nordson EFD, East Providence, RI) with a V...

example 2

[0115] Example 2. Slow Elution of Silver Nitrate

[0116] An eluting solution was prepared by adding 20 ml of ionic strength modifier (sodium nitrate solution, Orion 940011, ThermoFisher Scientific, Waltham, MA) to 1 liter of distilled water, followed by 0.03 g of sodium bicarbonate. A catheter coated with 89.9 mg of total silver nitrate as described in Example 1 was placed in 150 ml of this elution solution in a capped 500 ml Erlenmeyer flask at 37°C with rotary shaking at 50 rpm. The elution solution was changed daily and the silver content of each elution change was measured using a silver ion selective electrode (Orion IonPlus silver / sulfide electrode, ThermoFisher Scientific, Waltham, MA) and an instrument (Orion Star 214 pH / ISE meter, ThermoFisher Scientific, Waltham, MA). Table 1 shows the resulting silver content in mg / L silver ion.

[0117] Table 1.

[0118]

example 3

[0119] Example 3. Silver nitrate loading

[0120] Primer-coated pieces coated as in Example 1 were weighed in triplicate and then coated with silver nitrate as described in Example 1 with varying nozzle stroke capacities. After drying overnight, catheters were reweighed in triplicate. Table 2 contains weights showing different application of silver nitrate depending on nozzle width. A second coat of silver nitrate can be applied, repeating the conditions in Example 1B. The weight after drying overnight at room temperature is also shown in Table 2.

[0121] Table 2.

[0122]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com