Electronic commutation control system and control method for variable-capacitance electrostatic motor

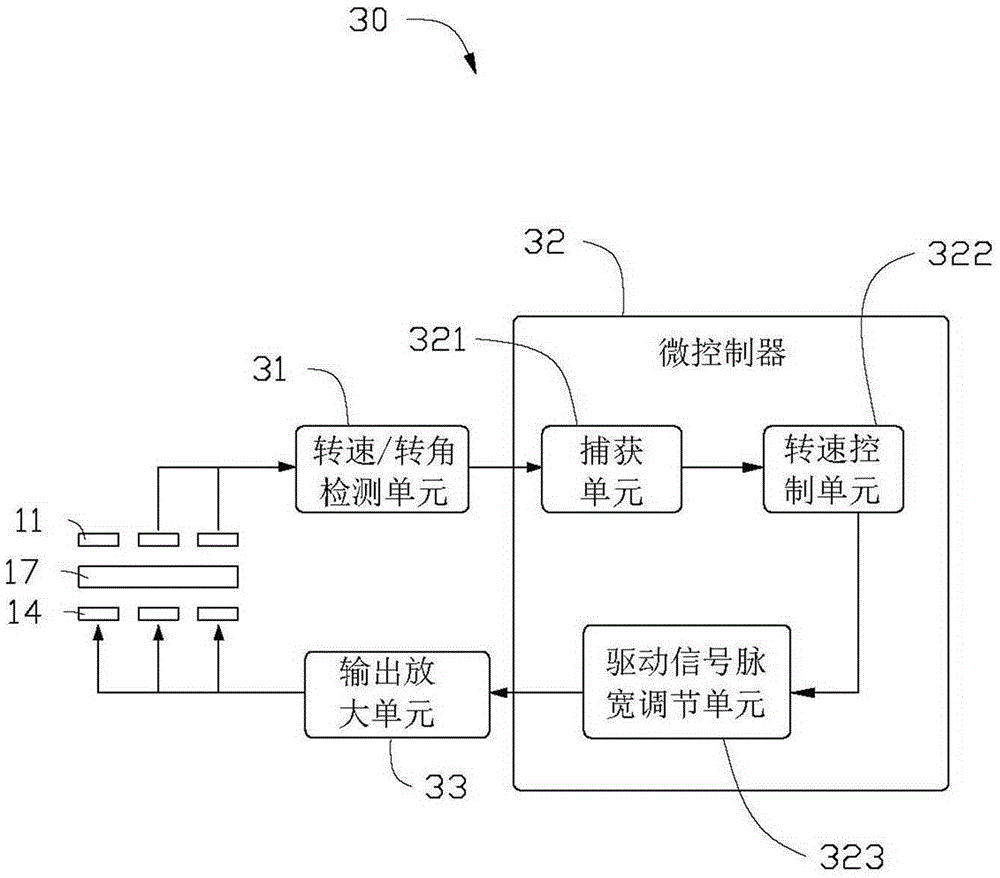

A technology of electronic commutation and variable capacitance, which is applied in the direction of electrostatic generator/motor, electrostatic motor, generator/motor, etc., can solve the problems of stator drive pulse out-of-step, long add-on time, motor out-of-step, etc., to achieve Reduce the starting time and solve the effect of motor out of step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The electronic commutation control system and control method of the variable capacitance electrostatic motor provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

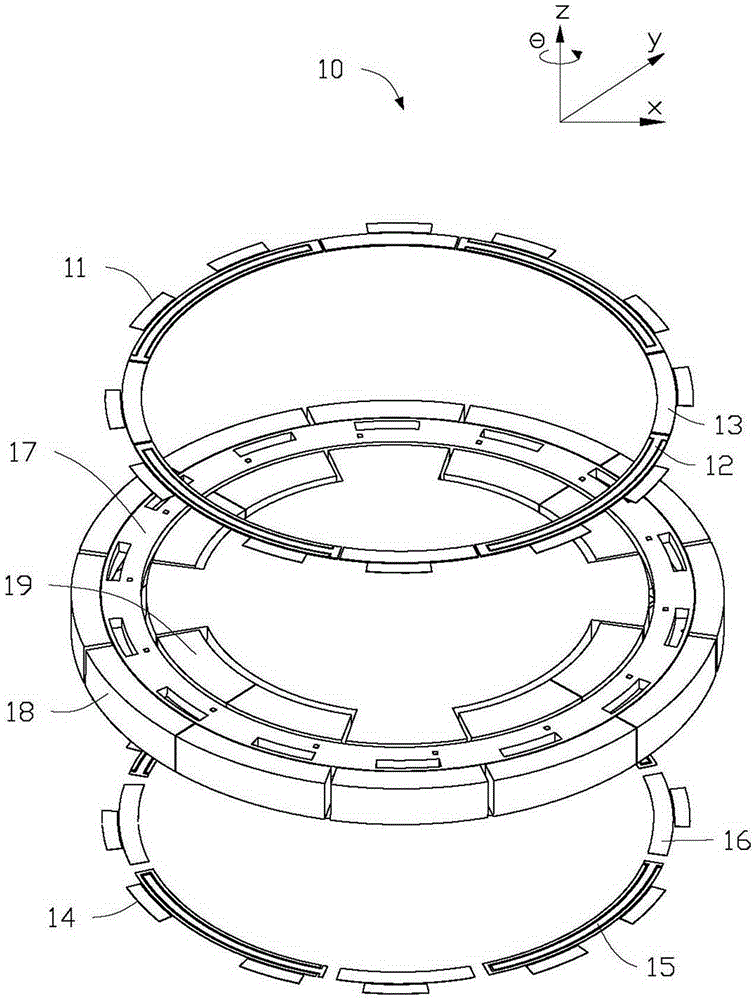

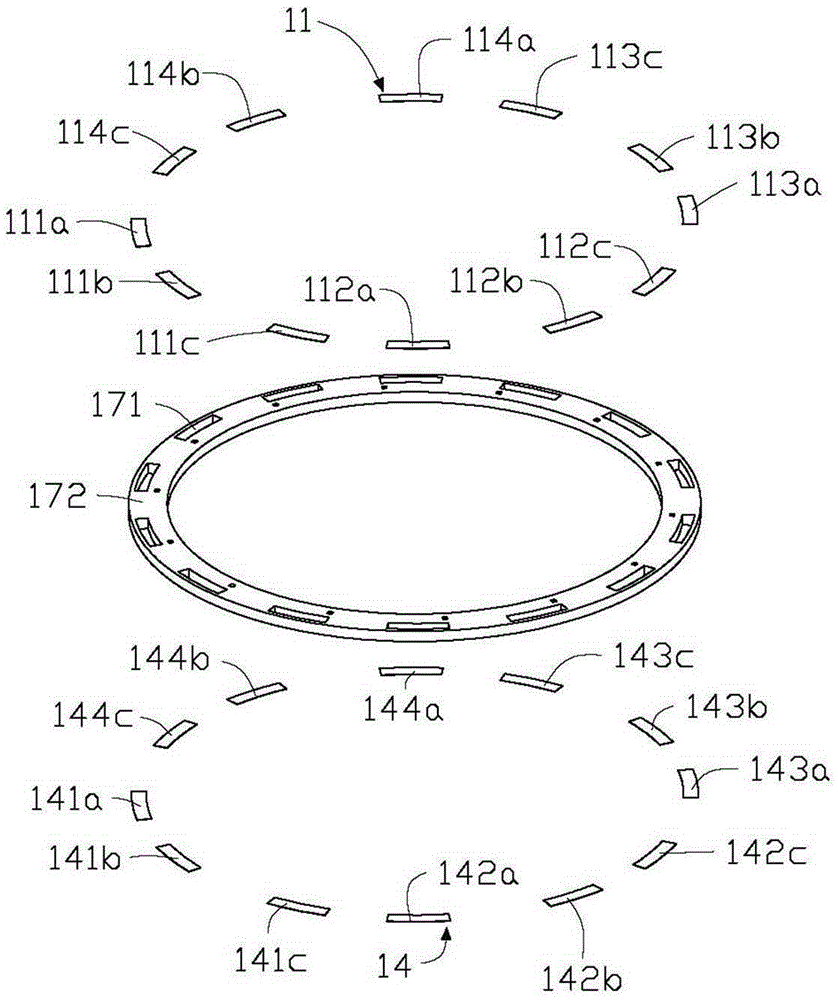

[0015] see figure 1 , The silicon micro-static levitation motor 10 includes a three-layer structure of top glass, middle layer of highly doped silicon, and bottom glass. There are upper stator 11 , axial suspension electrode 12 and common electrode 13 on the glass surface of the top layer. There are lower stator 14 , axial suspension electrode 15 and common electrode 16 on the bottom glass. There is a rotor 17 on the middle highly doped silicon layer, and in the radial direction of the rotor 17, there are suspended electrodes 18 with an outer diameter and suspended electrodes 19 with an inner diameter. The rotor 17 maintains a micron-scale gap with the upper stator 11, the lower stator 14, the axial suspension ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com