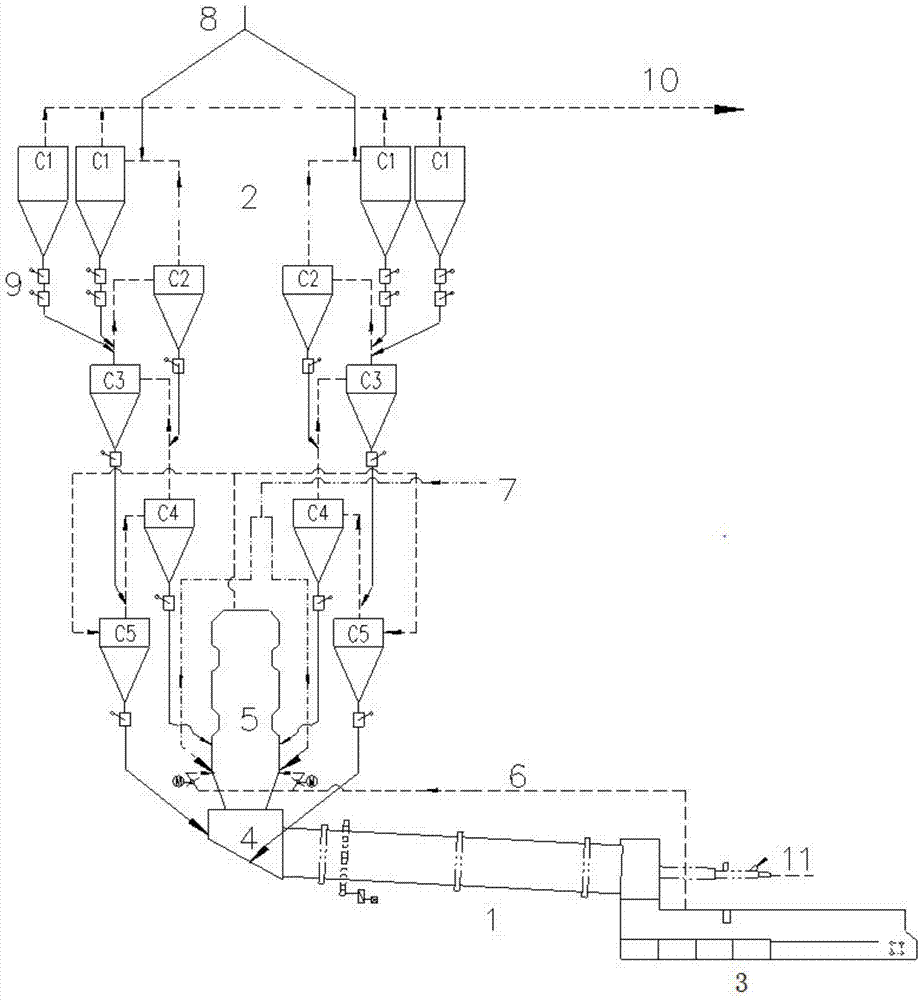

Air-coal graded low-nitrogen combustion equipment and technology and cement clinker firing system

A low-nitrogen combustion and air-coal technology, applied in combustion equipment, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of increased safety management costs, low reduction efficiency, sticky materials, etc., and achieve improved reduction efficiency and improved Good reduction efficiency and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

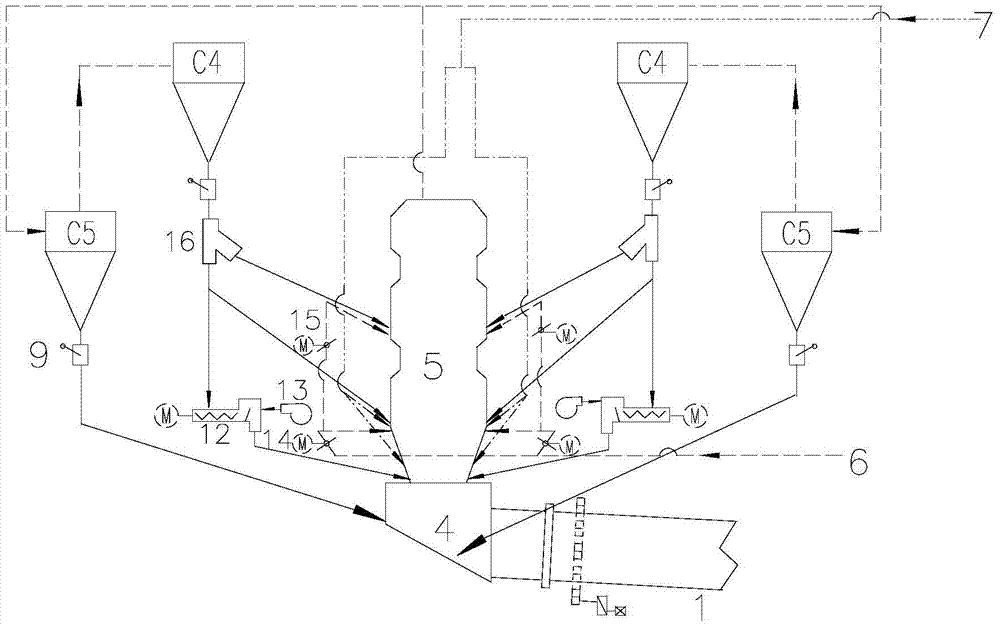

[0059] The air-coal graded low-nitrogen combustion equipment in this embodiment includes a decomposition furnace 5, a tertiary air valve 14, a cyclone C4-C5, a rotary kiln 1, a flap valve 9, a high-temperature-resistant air-locking screw conveyor 12, a Roots blower 13, Add a tertiary air valve 15 and a material distribution valve 16, the calciner 5 is provided with a tertiary air inlet and a new tertiary air inlet that is separated, and the tertiary air main pipeline passes through the tertiary air valve 14 and the tertiary air on the calciner 5. Inlet connection; on the tertiary air main pipeline after the tertiary air valve 14, a tertiary air branch pipeline is established, and a newly added tertiary air valve 15 is set on the tertiary air branch pipeline, and the tertiary air branch pipeline is newly added through the tertiary air valve 15 It is connected with the new inlet of the tertiary air that is separated; the calciner 5 is divided into the reduction and decomposition ...

Embodiment 2

[0071] The connection relationship and process steps of the air-coal material graded low-nitrogen combustion equipment in this embodiment are the same as in Embodiment 1, except that the distance between the lateral position of the spray pipe described in the equipment in this embodiment and the lower end surface of the calciner cone is 0.7m, and the injection pipe is always in the reduction and decomposition zone, the angle between the nozzle center line of the injection pipe and the horizontal direction is 25°; the distance between the coal injection pipe in the reduction and decomposition zone and the lower end surface of the calciner cone 1m. The sectional area of the tertiary air branch pipeline is 40% of the sectional area of the tertiary air main pipeline. The total height of reduction decomposition zone and reduction inhibition zone is 12m.

[0072] There are four material injection pipes in the reduction and decomposition area 5-1, four coal injection pipes in th...

Embodiment 3

[0074] The connection relationship of the air-coal material classification low-nitrogen combustion equipment in this embodiment and the steps of the process are the same as in Embodiment 1, the difference is that there is only one tertiary air inlet for the tertiary air to enter the calciner, and the total tertiary air after passing through the tertiary air valve 14 There is only one tertiary wind branch pipeline on the pipeline. Two reduction and decomposition zone thermocouples are installed on the circle with a distance of 1m downward from the lower edge of the inlet of the tertiary air. The two reduction and decomposition zone thermocouples are located on the same circle, and the angle between them is 90°; A thermocouple in the reduction inhibition zone is installed on a circle with a distance of 1m upward from the upper edge of the inlet of the tertiary air;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com