Reactive dye band wax dyeing method and low liquid supply padder

A technology of reactive dyes and low liquid supply, which is applied in the field of batik, can solve the problems of high degree of hydrolysis, high production cost, and difficult control, and achieve the effect of reducing ammonia nitrogen content, adapting to environmental protection requirements, and ensuring the wax sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

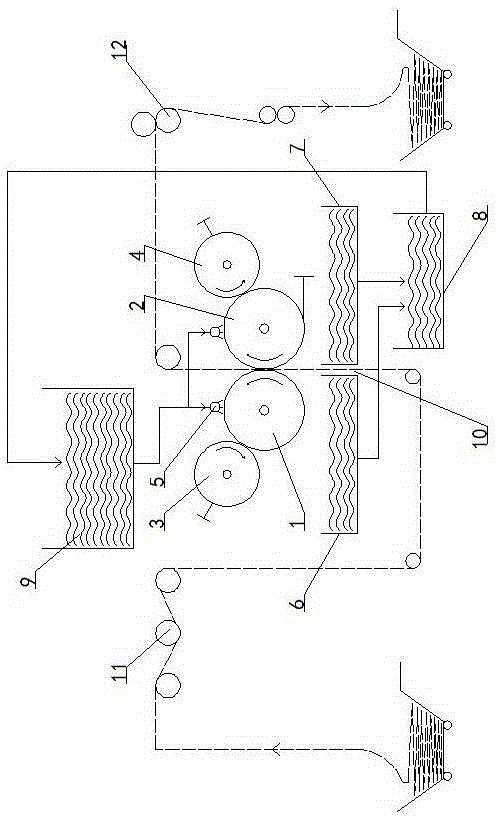

[0045] as attached figure 1 As shown, the low liquid feeding pad car of the present invention is mainly composed of the first traction roller 1, the second traction roller 2, the first liquid supply control roller 3, the second liquid supply control roller 4, the liquid supply pipe 5, the first Color-fixing liquid collection tank 6, the second color-fixing liquid collection tank 7, total collection tank 8, and color-fixing liquid feeding tank 9 constitute.

[0046] The first traction roller 1 and the second traction roller 2 are arranged in parallel in the horizontal direction and are rolled together.

[0047] The first liquid supply control roller 3 and the first traction roller 1 are in contact with each other, and are arranged on the side of the first traction roller 1 away from the second traction roller 2 . The second liquid supply control roller 4 is in contact with the second pulling roller 2 , and is arranged on a side of the second pulling roller 2 away from the firs...

Embodiment 2

[0055] The technological process of the reactive dye wax printing and dyeing method of the present invention is machine wax printing dry cloth → reactive cold dyeing → drying → low liquid level rolling and color fixing → stacking → open width washing alkali → hot and cold rope wax removal water washing.

[0056] (1) Machine wax printing dry drop cloth

[0057] Complete the wax printing dry drop cloth process with the conventional wax printing machine in the prior art;

[0058] (2) active cold dyeing

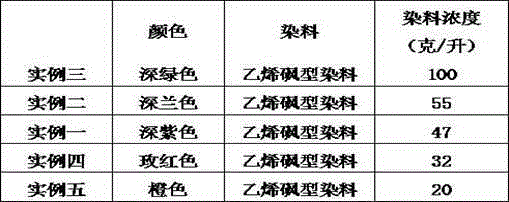

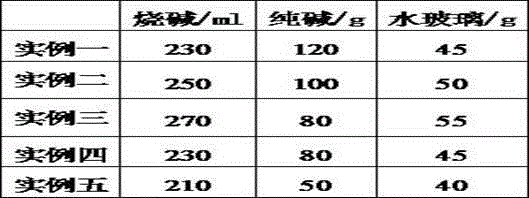

[0059] Finished with conventional cold dyeing equipment in the prior art, the formula of the dye solution is shown in the following table:

[0060]

[0061] (3) drying

[0062] The drying process is completed with the conventional wax drying machine in the prior art, the drying temperature is controlled at about 120°C, the speed of the vehicle is 30 m / min, and the falling cloth is not stained with wax and can be slightly dry;

[0063] (4) Rolling and fixing color at low liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com