A kind of high-efficiency selective water shutoff agent for oil field and preparation method thereof

A water plugging agent and high-efficiency technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of polymer plugging agents' poor resistance to mineral pollution, high production cost of oil-based plugging agents, and alcohol-based plugging agents. Complex problems, to achieve strong selective water blocking effect, small damage, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

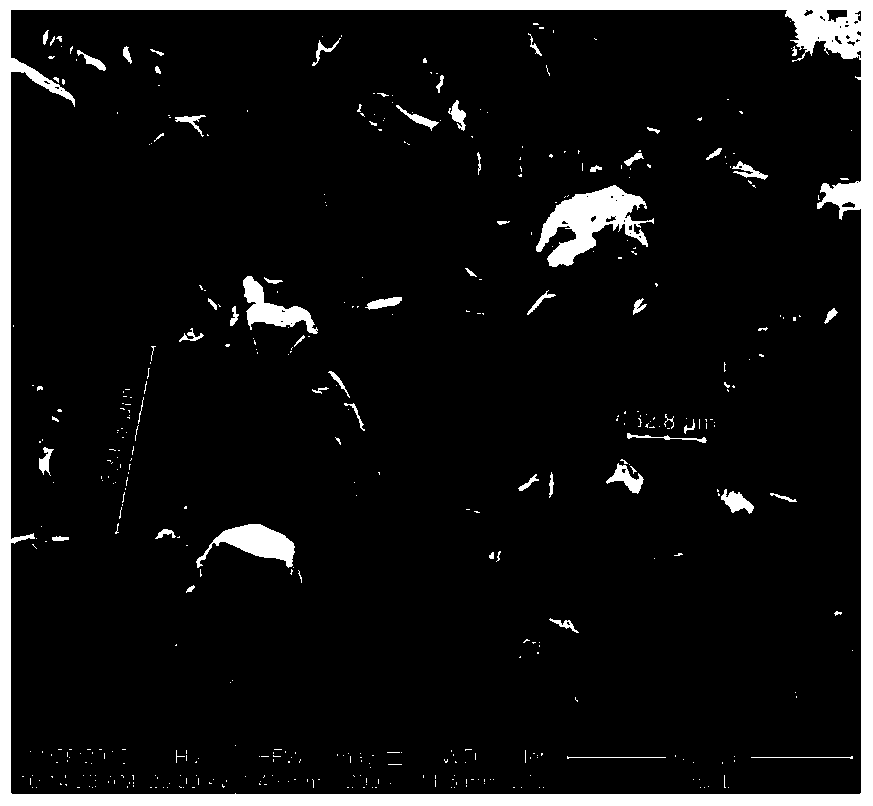

Image

Examples

Embodiment 1

[0043] The high-efficiency selective water shutoff agent for oilfields in this embodiment, the synthetic monomers and the dosage are: 22.0% carboxymethylacrylamide, 12.0% acrylic acid, 6.0% 2-acrylamide-2-methylpropanesulfonic acid, dimethyl dimethicone Allyltrimethylammonium chloride 3.0%, GL-1 0.1%, WD-80 0.1%, k 2 S 2 o 8 0.3%, Na 2 SO 3 0.15%.

[0044] The method for preparing the above-mentioned embodiment 1 water blocking agent is as follows:

[0045] Step 1: At room temperature, add 50 mL of deionized water to the three-necked flask, and at the same time pass nitrogen gas to discharge the air in the flask;

[0046] Step 2: Turn on the agitator and add 11.0g carboxymethylacrylamide, 6g acrylic acid, 3g 2-acrylamide-2-methylpropanesulfonic acid, 1.5g dimethyldiallyltrimethyl chloride while stirring Ammonium, then fully stirred to make it fully dissolved;

[0047] Step 3: Add 0.05g of silicone coupling agent GL-1 and 0.05g of silicone coupling agent WD-80, and the...

Embodiment 2

[0053] The high-efficiency selective water shutoff agent used in oil fields in this embodiment, the synthetic monomers and the dosage are: 18.0% of acrylamide, 12.0% of methyl silicic acid, 6.0% of 2-acrylamide-2-methylpropanesulfonic acid, dimethyl dimethicone Allyltrimethylammonium chloride 3.0%, GL-10.15%, WD-80 0.15%, k 2 S 2 o 8 0.3%, Na 2 SO 3 0.15%.

[0054] The method for preparing the above-mentioned embodiment 2 water blocking agent is as follows:

[0055] Step 1: At room temperature, add 50 mL of deionized water to the three-necked flask, and at the same time pass nitrogen gas to discharge the air in the flask;

[0056] Step 2: Turn on the agitator, add 9.0g acrylamide, 6g methyl silicic acid and 3g 2-acrylamide-2-methylpropanesulfonic acid, 1.5g dimethyl diallyl trimethyl chloride while stirring Ammonium, then fully stirred to make it fully dissolved;

[0057] Step 3: Add 0.075g of silicone coupling agent GL-1 and 0.075g of silicone coupling agent WD-80, a...

Embodiment 3

[0063] The high-efficiency selective water shutoff agent for oilfields in this embodiment, the synthetic monomers and the dosage are: 18.0% of acrylamide, 12.0% of acrylic acid, 6.0% of 2-acrylamide-2-methylpropanesulfonic acid, methacryloyloxyethyl Trimethylammonium chloride 3.0%, GL-10.15%, GL-2 0.10%, k 2 S 2 o 8 0.3%, Na 2 SO 3 0.15%.

[0064] The method for preparing the above-mentioned embodiment 3 water blocking agent is as follows:

[0065] Step 1: At room temperature, add 50 mL of deionized water to the three-necked flask, and at the same time pass nitrogen gas to discharge the air in the flask;

[0066] Step 2: Turn on the agitator, add 9.0g acrylamide, 6g acrylic acid and 3g 2-acrylamide-2-methylpropanesulfonic acid, 1.5g methacryloxyethyltrimethylammonium chloride while stirring, and then Stir well to make it fully dissolved;

[0067] Step 3: Add 0.075g of silicone coupling agent GL-1 and 0.05g of silicone coupling agent GL-2, then fully stir to fully diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com