Water plugging method of establishing large-area chemical partition plate in gas-water interface of water-bearing gas reservoir

A gas-water interface and large-area technology, applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc., can solve the problems of small sealing range and low sealing strength, so as to prevent edge water from advancing and improve The effect of recovery factor and excellent salt interception ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A water shutoff method for establishing a large-area chemical partition at the gas-water interface of a water-containing gas reservoir, comprising the following steps in sequence:

[0049] (1) Prepare 100ml of an aqueous solution with a mass fraction of 3% m-phenylenediamine, and adjust the pH to 11 with NaOH solution;

[0050] (2) Prepare 100ml of a cyclohexane solution with a mass fraction of 0.5% 1,3,5-trimesoyl chloride, and add 0.5ml of octylphenol polyoxyethylene ether (OP-10) and stir evenly;

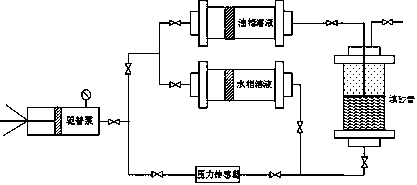

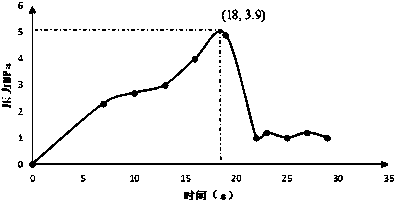

[0051] (3) Take 10ml of the water phase solution and inject it from the bottom of the sand filling pipe until the water phase solution reaches the middle of the sand filling pipe; then inject 5ml of the oil phase solution from the top of the sand filling pipe and wait to spread to form a polymer interlayer (For the plugging performance evaluation process, see figure 2 ), after two minutes of reaction, put the sand-filled tube into a 60°C oven to fully carry out the polym...

Embodiment 2

[0057] A water shutoff method for establishing a large-area chemical partition at the gas-water interface of a water-containing gas reservoir, comprising the following steps in sequence:

[0058] (1) Prepare 100ml of an aqueous solution of polyethyleneimine (PEI) with a mass fraction of 2% and a relative molecular mass of 600, and adjust the pH to 11 with NaOH solution;

[0059] (2) prepare 100ml mass fraction and be the cyclohexane solution of 0.5% 1,3,5-trimesoyl chloride, and add 0.5ml polyethoxytrisiloxane (ethoxy modified polytrisiloxane ) stir evenly;

[0060] (3) Take 10ml of the water phase solution and inject it from the bottom of the sand filling pipe until the water phase monomer reaches the middle of the sand filling pipe to establish the air-water interface; then inject 5ml of the oil phase solution from the top of the sand filling pipe and wait Spread to form a polymer interlayer (see the plugging performance evaluation process for figure 2 ), after two minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com