PDGA resin and preparation method and application thereof

A resin and reaction technology, applied in the field of cigarette harm reduction additive materials, can solve the problems of poor selectivity of adsorbents, increased cost, complicated processes, etc., and achieve the effect of reducing the release amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

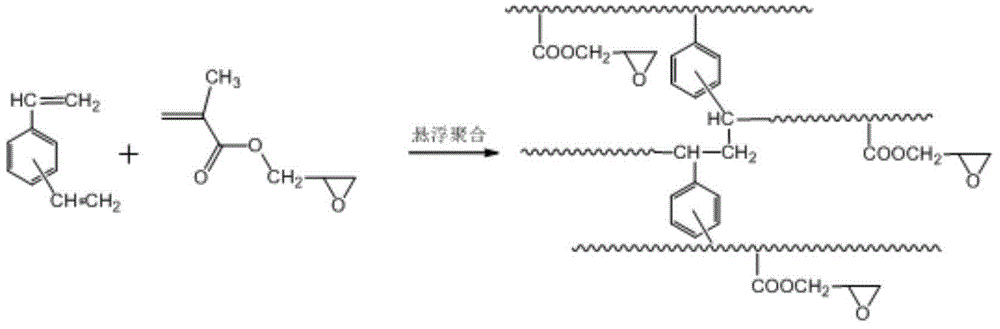

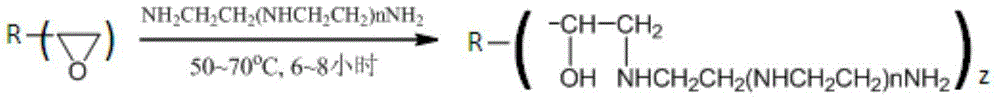

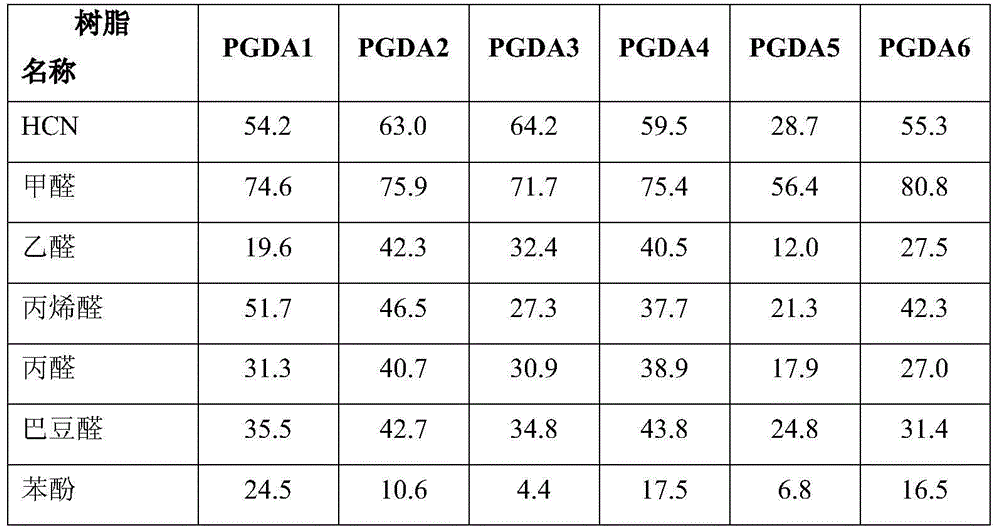

Method used

Image

Examples

Embodiment 1

[0058] (1) Dissolve 5g of polyvinyl alcohol and 22.5g of sodium chloride in 422.5g of water in a 1L three-necked bottle, and make an aqueous solution to obtain the aqueous phase of suspension polymerization (wherein the concentration of polyvinyl alcohol in the aqueous phase is 1.1wt%, chlorination The concentration of sodium is 5wt%), and heated to 40 ° C;

[0059] In addition, 32g polymerized monomer DVB (purity 55%, wt%), 16g polymerized monomer GMA (the mass ratio of DVB and GMA is 2), mixed porogen 24g toluene and 24g n-heptane (toluene and long-chain alkanes normal The mass ratio of heptane is 1, the mass ratio of mixed porogen and total polymerized monomer is 1), 1.0g initiator azobisisobutyronitrile (AIBN) (initiator accounts for 2.1wt% of total polymerized monomer quality ) after mixing evenly to obtain the oil phase of the suspension polymerization reaction, add the oil phase to the above water phase (the mass ratio of the water phase to the oil phase is 4.6), start ...

Embodiment 2

[0064] (1) 2.5g polyvinyl alcohol and 13.5g sodium chloride are dissolved in 434.0g water in 1L there-necked bottle, are made into aqueous solution and obtain the water phase of suspension polymerization (wherein the concentration of polyvinyl alcohol in water phase is 0.55wt%, chlorine The concentration of NaCl is 3wt%), and heated to 35°C;

[0065] In addition, 45gDVB (purity 55%, wt%) and 5gGMA (the mass ratio of DVB and GMA is 9), 34g toluene and 66g n-heptane (the mass ratio of toluene and long-chain alkane n-heptane is 1:1.9, mixed to The mass ratio of pore agent and total polymerized monomer is 2), after 0.75g benzoyl peroxide (BPO) (initiator accounts for 1.5%wt of total polymerized monomer quality) mixes homogeneously, obtain the oily phase of suspension polymerization reaction, Add the oil phase to the water phase (the mass ratio of the water phase to the oil phase is 3), and simultaneously raise the temperature of the reaction system to 78° C. for 3 hours, then rais...

Embodiment 3

[0070] (1) 22.5g polyvinyl alcohol and 45g sodium chloride are dissolved in 1432.5g water in 3L there-necked bottle, are made into aqueous solution and obtain the water phase of suspension polymerization (wherein the concentration of polyvinyl alcohol in the water phase is 1.5wt%, chlorination The sodium concentration was 3 wt%) and heated to 45°C.

[0071] With 140.4gDVB (purity 78.4%, wt%), 47.1gGMA (the mass ratio of DVB and GMA is 3), 125.1g toluene and 62.4g200 # Gasoline (toluene and long chain alkanes 200 # The mass ratio of gasoline is 2:1, the mass ratio of mixed porogen and total polymerized monomer is 1), 3.75g azobisisobutyronitrile (AIBN) (initiator accounts for 2wt% of total polymerized monomer mass) mixed Obtain the oil phase of the suspension polymerization reaction after uniformity, add the oil phase to the above-mentioned water phase (the mass ratio of the water phase to the oil phase is 4), start stirring, and simultaneously raise the temperature of the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com