Method of treating bilge water by combining Fenton's reagent with potassium hydrogen persulfate and microorganism

A technology of potassium hydrogen persulfate and Fenton reagent, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. research, marine pollution and other issues, to achieve the effect of strong pertinence, saving treatment costs and equipment running time, and increasing oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

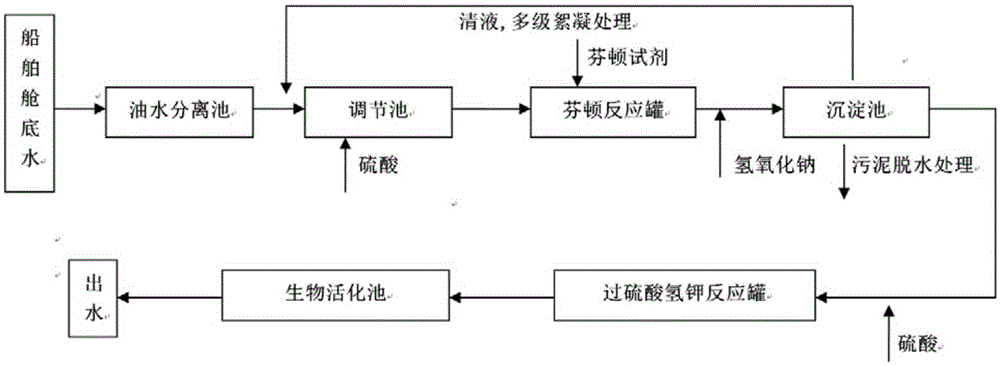

Method used

Image

Examples

Embodiment 1

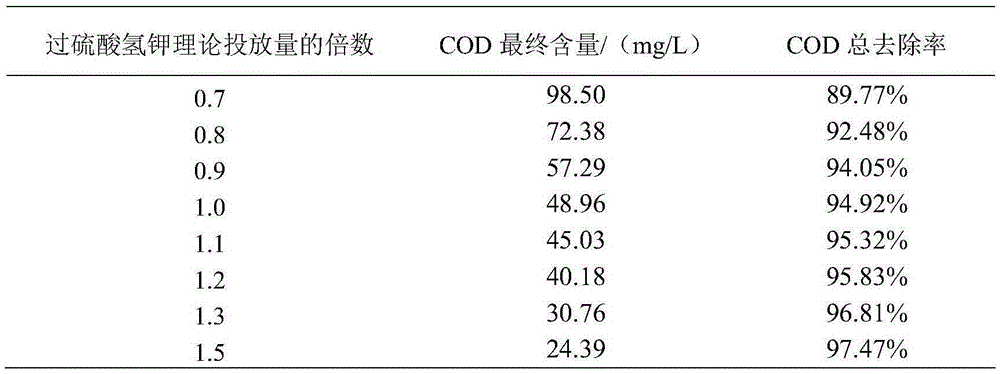

[0060] In this example, the bilge water after preliminary oil-water separation is the object to be treated. Bilge water COD Mn The content is 963mg / L, and the pH is 7.20. In Fenton's reagent, the mass concentration of hydrogen peroxide is 30%, and ferrous sulfate is prepared as an aqueous solution. Potassium hydrogen persulfate is a solid powder. The experiment was divided into five groups, which were dosed at 1 to 5 times the theoretical dose of Fenton's reagent. After the reaction is completed, the COD in the water is determined by analysis Mn And the content of ammonia nitrogen, the removal efficiency of reducing substances such as organic matter in the bilge water was evaluated. The results are shown in Table 1. From the data in the table, it can be seen that after three Fenton’s reagent oxidation reactions, the theoretical dosage of Fenton’s reagent is 2-5 times the bilge water COD Mn The removal effect is the best and the difference is less than 5%, and the ammonia nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com