A kind of method for rapidly preparing polycrystalline tetracalcium ferric aluminate

A technology of polycrystalline iron and alumina, applied in chemical instruments and methods, iron compounds, sustainable manufacturing/processing, etc., can solve the problem of high calcination temperature of solid phase sintering method, which is unfavorable for industrial scale production and application, and synthesis It is difficult to guarantee the uniformity of the product and other problems, and achieve the effect of shortening the preparation cycle, overcoming the difficulty of mixing powder raw materials, and improving the synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Purpose: To prepare 20g polycrystalline tetracalcium aluminoferrite

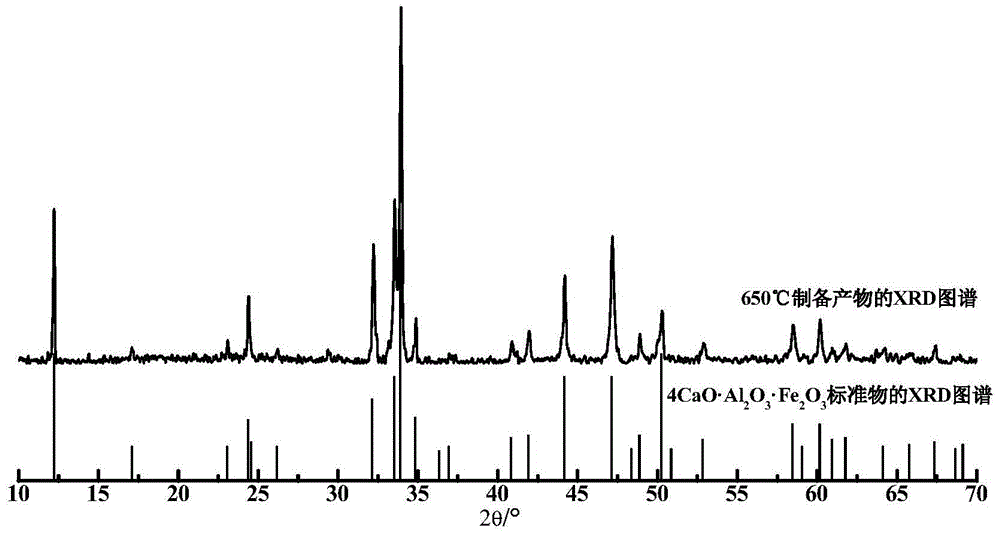

[0046] According to the chemical formula of tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 The calculated CaO content is 46.1580%, Al 2 o 3 The content is 20.9814%, Fe 2 o 3 The content is 32.8606%. According to the mass of tetracalcium aluminoferrite to be prepared is 20g, the content of CaO in the sample is calculated to be 20.0×46.1580%=9.2316g.

[0047] According to the mass conservation of Ca element, the required analytically pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 The mass of O is 9.2316×4.2111=38.8752g

[0048] Analytical pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 0.7942 times and 0.8554 times of the mass of O to calculate and analyze pure aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O, analytically pure iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 The masses of O are 38.8752×0.7942=30.8747g, 38.8752×0.8554=33.2538g respectively.

[0049] Analytical ...

Embodiment 2

[0055] Objective: To prepare 12g polycrystalline tetracalcium aluminoferrite

[0056] According to the chemical formula of tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 The calculated CaO content is 46.1580%, Al 2 o 3 The content is 20.9814%, Fe 2 o 3 The content is 32.8606%. According to the mass of tetracalcium aluminoferrite to be prepared is 12g, the content of CaO in the sample is calculated to be 12.0×46.1580%=5.5390g.

[0057] According to the mass conservation of Ca element, the required analytically pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 The mass of O is 5.5390×4.2111=23.3253g.

[0058] Analytical pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 0.7942 times and 0.8554 times of the mass of O to calculate and analyze pure aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O, analytically pure iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 The masses of O are 23.3253×0.7942=18.5250g and 23.3253×0.8554=19.9525g respectively.

[0059] Analy...

Embodiment 3

[0065] Objective: To prepare 15.6g polycrystalline tetracalcium aluminoferrite

[0066] According to the chemical formula of tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 The calculated CaO content is 46.1580%, Al 2 o 3 The content is 20.9814%, Fe 2 o 3 The content is 32.8606%. According to the mass of tetracalcium aluminoferrite to be prepared is 12g, the content of CaO in the sample is calculated to be 15.6×46.1580%=7.2006g.

[0067] According to the mass conservation of Ca element, the required analytically pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 The mass of O is 7.2006×4.2111=30.3224g.

[0068] Analytical pure calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 0.7942 times and 0.8554 times of the mass of O to calculate and analyze pure aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O, analytically pure iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 The masses of O are 30.3224×0.7942=24.0821g and 30.3224×0.8554=25.9378g respectively.

[0069] Ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com