Method for preparing 4A molecular sieves by using tailings and application of 4A molecular sieves

A molecular sieve and tailings technology, which is applied to the removal of solid waste, A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of high raw material cost and expensive price, and achieve good recovery effect and good The effect of reusable performance and reducing the time of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material is tailings, mainly containing SiO2, Al2O3, a small amount of elements such as Fe, K, Ca, Mg, Ti, P, Zn, the main chemical composition is as follows (%wt):

[0026]

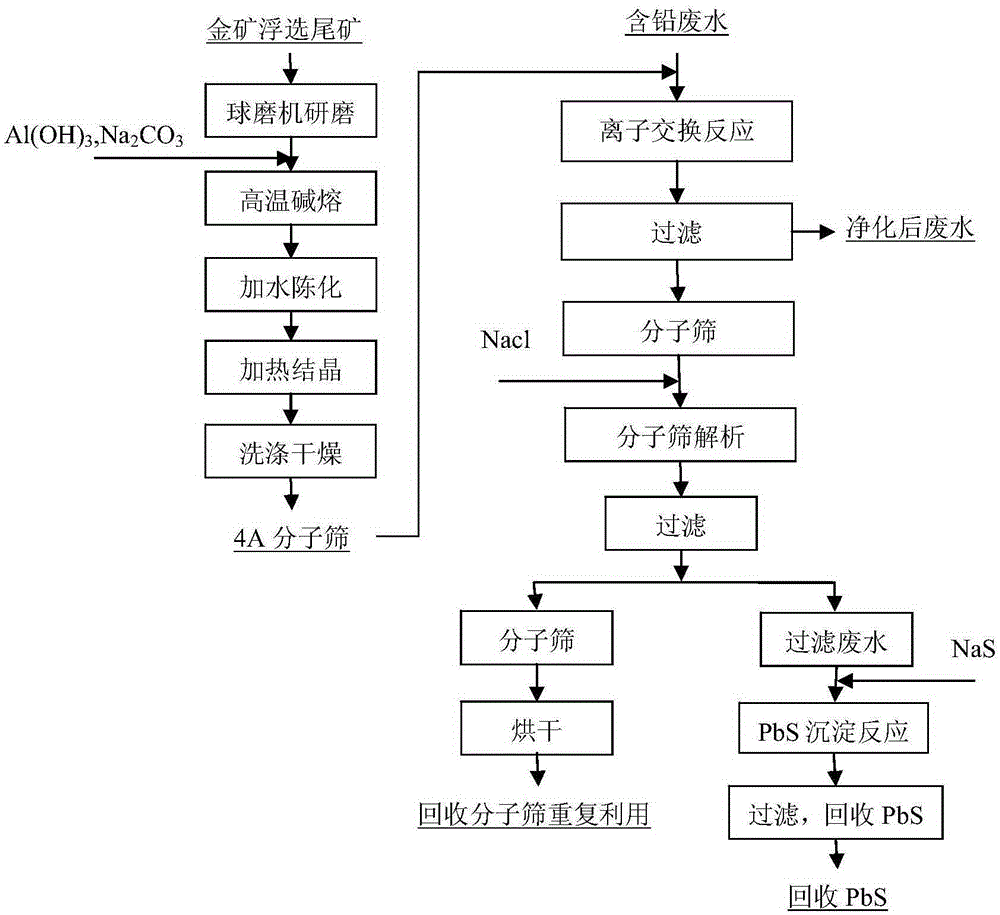

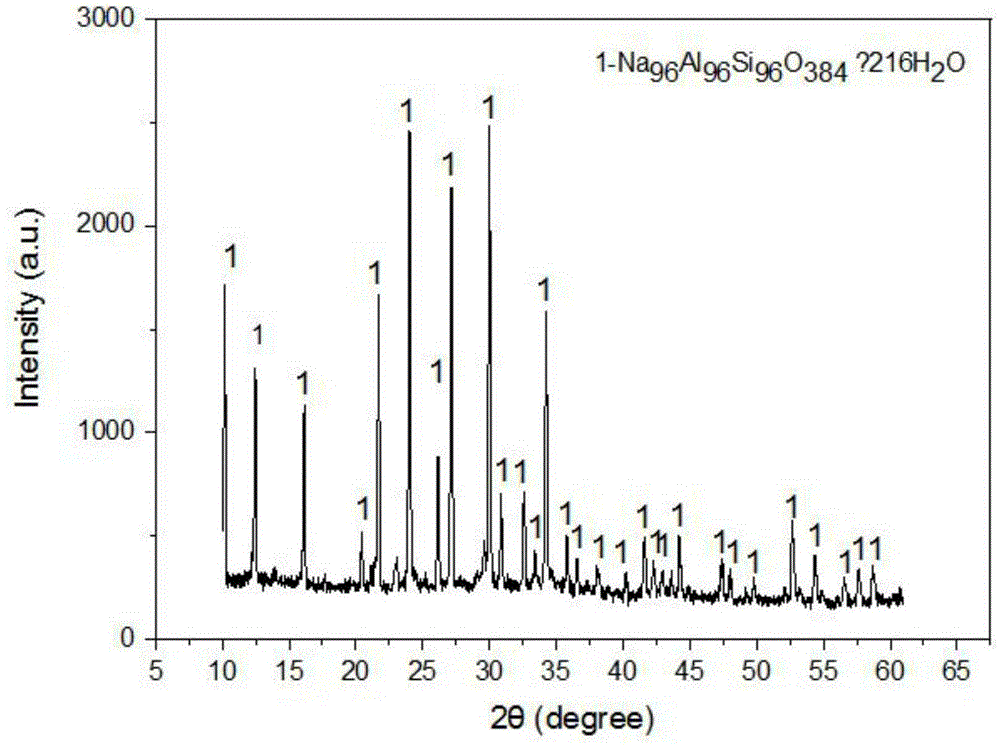

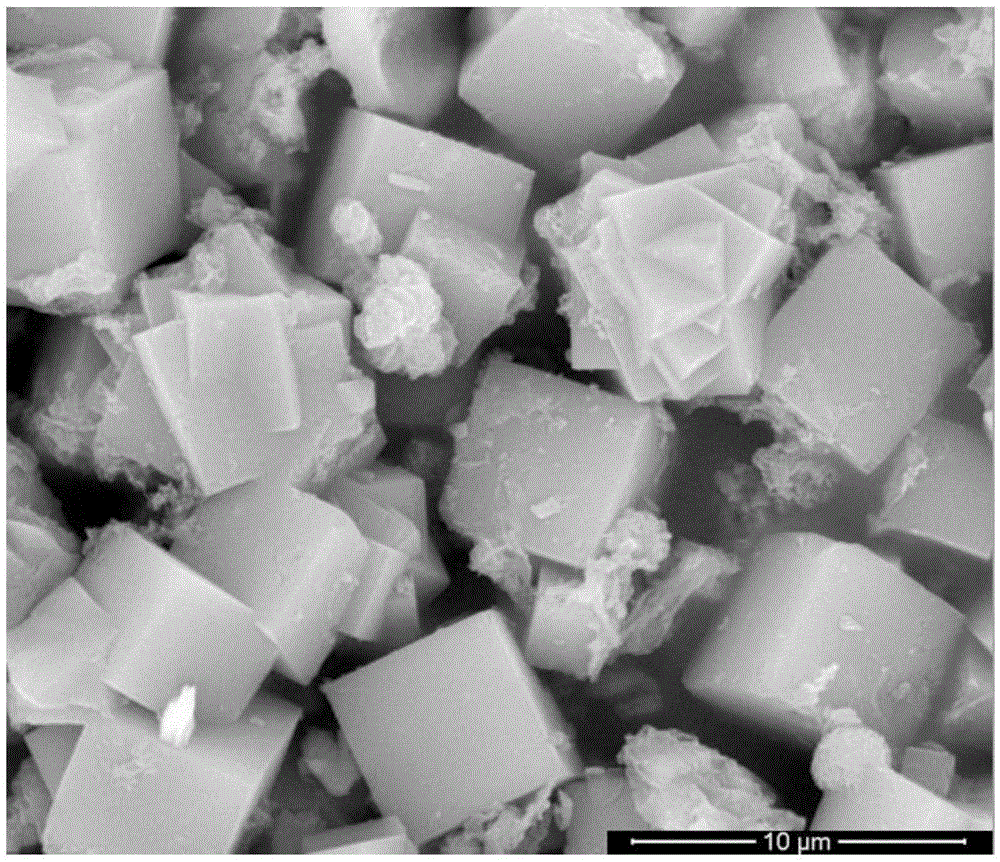

[0027] Synthesis of 4A molecular sieve steps using tailings:

[0028] High-temperature alkali fusion: The tailings are ground to 325 mesh, mixed with a certain amount of solid Na2CO3 and solid Al(OH)3, placed in a crucible and then heated at high temperature for reaction. The heating temperature is 855°C, heating and holding for 2 hours, the mass ratio of sodium carbonate to silicon dioxide is 1:1.2, and the molar ratio of silicon dioxide to alumina is 2.

[0029] Add water and age: add water to the ore sample after the above steps and age with stirring for 20 hours. The mass ratio of ore to water is 1:8.

[0030] Heating crystallization: the above-mentioned ore samples are placed in a reaction kettle, heated and kept for a certain period of time. The temperature is 100°C and the tim...

Embodiment 2

[0041] The raw material is tailings, mainly containing SiO2, Al2O3, a small amount of elements such as Fe, K, Ca, Mg, Ti, P, Zn, the main chemical composition is as follows (%wt):

[0042]

[0043] Synthesis of 4A molecular sieve steps using tailings:

[0044] High-temperature alkali fusion: The tailings are ground to 325 mesh, mixed with a certain amount of solid Na2CO3 and solid Al(OH)3, placed in a crucible and then heated at high temperature for reaction. The heating temperature is 855°C, heating and holding for 2 hours, the mass ratio of sodium carbonate to silicon dioxide is 1:1.2, and the molar ratio of silicon dioxide to alumina is 2.

[0045] Add water and age: add water to the ore sample after the above steps and age with stirring for 20 hours. The mass ratio of ore to water is 1:8.

[0046]Heating crystallization: the above-mentioned ore samples are placed in a reaction kettle, heated and kept for a certain period of time. The temperature is 100°C and the time...

Embodiment 3

[0057] The raw material is tailings, mainly containing SiO2, Al2O3, a small amount of elements such as Fe, K, Ca, Mg, Ti, P, Zn, the main chemical composition is as follows (%wt):

[0058]

[0059] Synthesis of 4A molecular sieve steps using tailings:

[0060] High-temperature alkali fusion: The tailings are ground to 325 mesh, mixed with a certain amount of solid Na2CO3 and solid Al(OH)3, placed in a crucible and then heated at high temperature for reaction. The heating temperature is 855°C, heating and holding for 2 hours, the mass ratio of sodium carbonate to silicon dioxide is 1:1.2, and the molar ratio of silicon dioxide to alumina is 2.

[0061] Add water and age: add water to the ore sample after the above steps and age with stirring for 20 hours. The mass ratio of ore to water is 1:8.

[0062] Heating crystallization: the above-mentioned ore samples are placed in a reaction kettle, heated and kept for a certain period of time. The temperature is 100°C and the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com