Liquid acid alkylation reactor and application method thereof

An alkylation reactor and alkylation reaction technology, applied in chemical/physical/physical-chemical nozzle reactors, production of liquid hydrocarbon mixtures, petroleum industry, etc. Satisfaction of people, etc., to achieve the effect of saving equipment investment, easy processing, and speeding up the rate of alkylation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

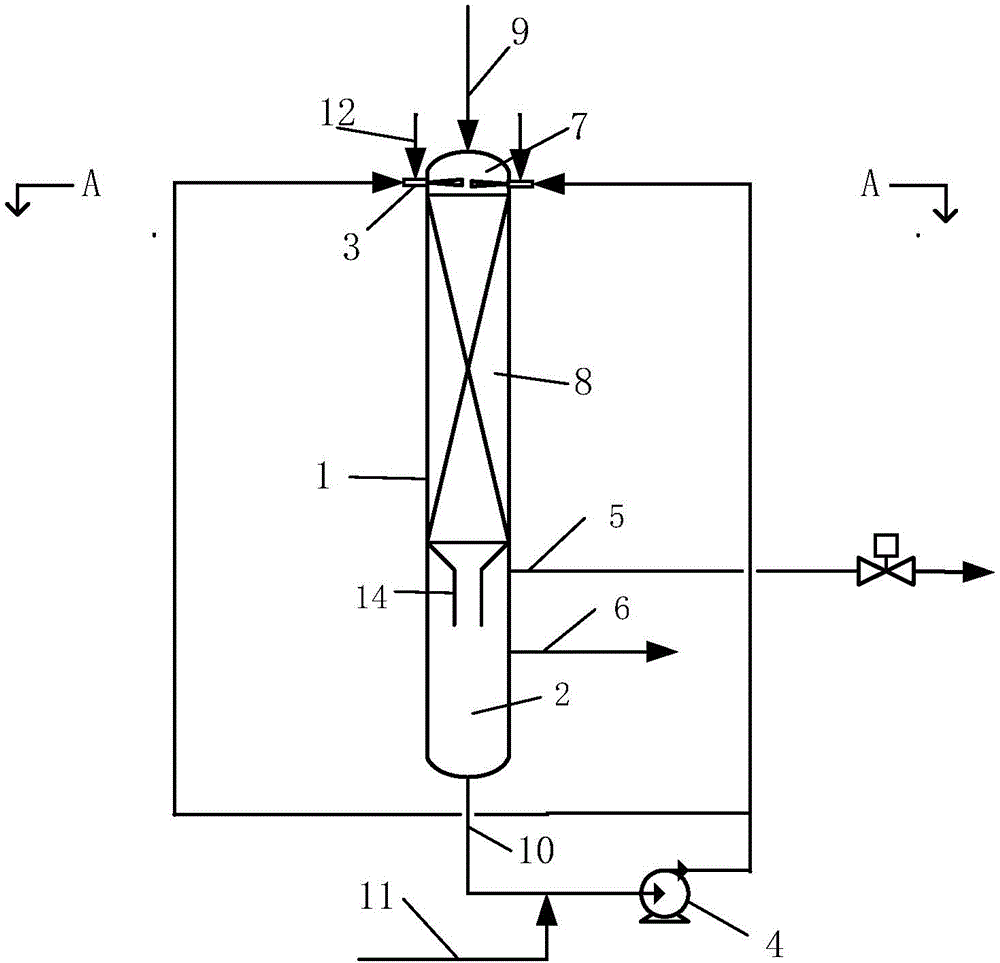

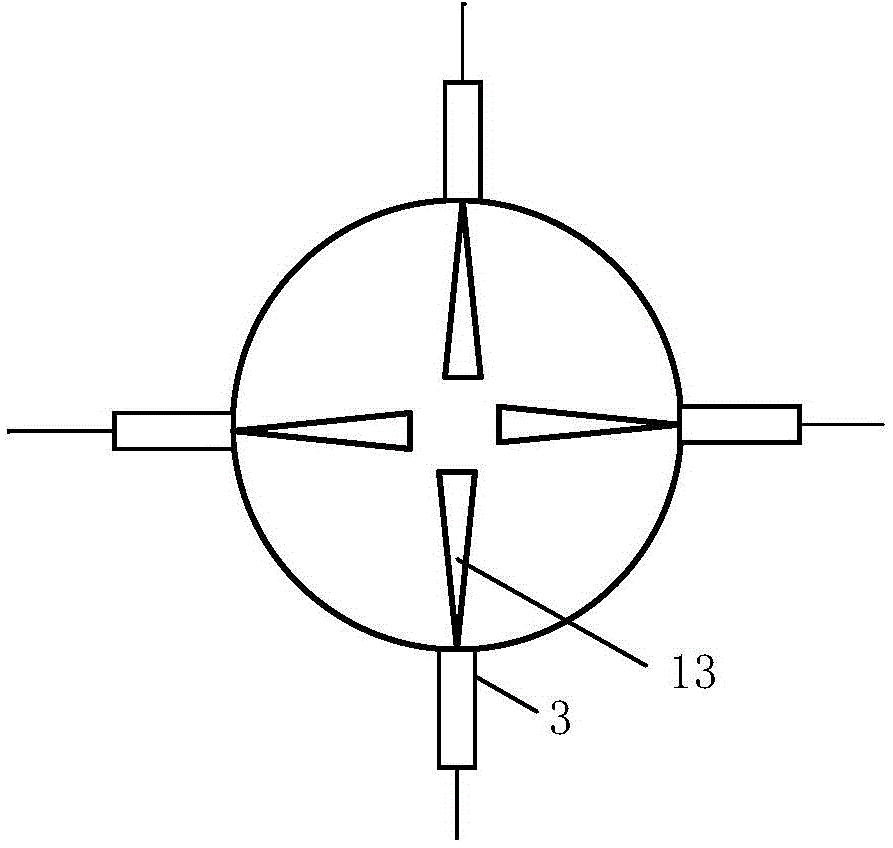

[0048] The structure of the liquid acid alkylation reactor is as attached figure 1 As shown, wherein, the diameter of the reactor is 2m, the height is 15m, the height of the mixing zone is 1.5m, 2 groups of jet mixers are arranged in the mixing zone, the height of the reaction zone is 10m, and the packed packing is capillary glass fiber structured packing, gas The position of the outlet is 3.5m, the position of the liquid phase product outlet is 0.5m, the shape of the conical guide tube is funnel-shaped, and the height is 2.5m.

[0049] The above-mentioned liquid acid alkylation reactor was used for the alkylation reaction, and the reaction raw material was C4 liquefied gas, which was obtained from Shijiazhuang Oil Refining and Chemical Industry Co., Ltd. The mass percent composition is: 0.098% of propane, 39.36% of isobutane, 13.51% of n-butane, 1.39% of isobutene, 14.70% of 1-butene, 14.92% of cis-butene, 16.0% of trans-butene and 0.022% of pentane. Control the alkene ratio...

Embodiment 2

[0051] Adopt the liquid acid alkylation reactor in the embodiment 1 to carry out the alkylation reaction, the reaction process and the reaction raw materials are the same as the embodiment 1, the difference is that the liquid acid catalyst is a mixture of concentrated sulfuric acid and trifluoromethanesulfonic acid, and the specific composition The 98.5% concentrated sulfuric acid accounts for 92%, and the trifluoromethanesulfonic acid accounts for 8%. Control the alkene ratio of the mixed hydrocarbons entering the reactor to be 10:1:1, the reaction pressure is 0.25MPa, and the temperature is 0°C. The alkylation reaction product is distilled to remove most of the carbon four components, and the obtained alkylated oil The dry point is 192°C, the RON value is 97.3, and the MON value is 95.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com