A nano-friction wind energy generator with grass structure

A nano-generator and nano-friction technology, applied in the direction of friction generators, etc., can solve the problems that cannot meet the needs of vibration mechanical collection, the structure of electromagnetic induction generators is complex, and the cost of materials has special requirements, so as to achieve enhanced friction electrification effect , Enhance the applicability of power generation, the effect of a wide range of practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

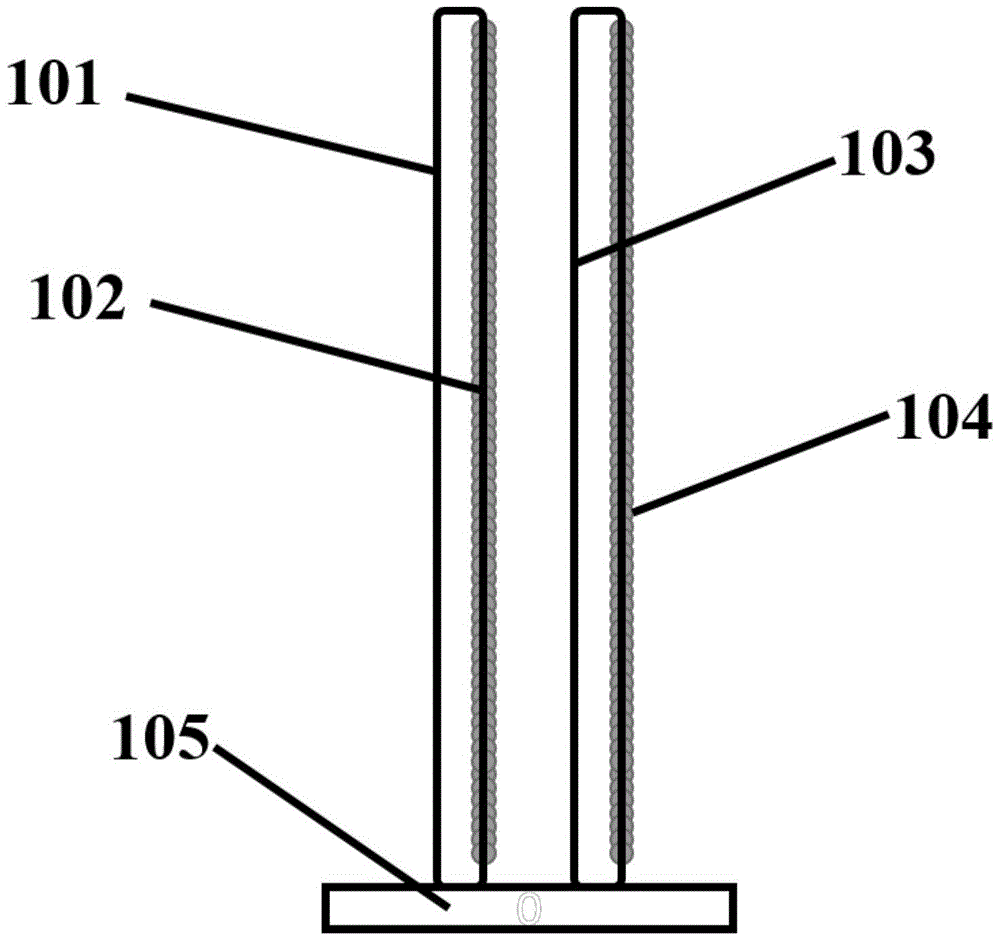

[0025] see figure 1 , the nano-friction wind energy generator of the grass structure comprises a plastic sheet substrate 105, and two elastic plastic sheets respectively comprise a first electrode layer 101 and a first friction layer 102, a second electrode layer 103 and a second friction layer 104, and the plastic sheet lining The bottom 105 is cut according to the shape of the plastic sheet to form a nano generator with a grass structure.

[0026] The plastic sheet substrate 105 has a certain mechanical strength, thickness and elasticity, and two elastic plastic films are inserted on the plastic sheet substrate 105 to form a nanogenerator with a grass structure; wherein, the front and back sides of the plastic film are provided with a first electrode layer 101, The first friction layer 102, at this time, the first electrode layer 101 serves as a back electrode, another plastic film has a second electrode layer 103, and the upper surface of the second electrode layer 103 is c...

Embodiment 2

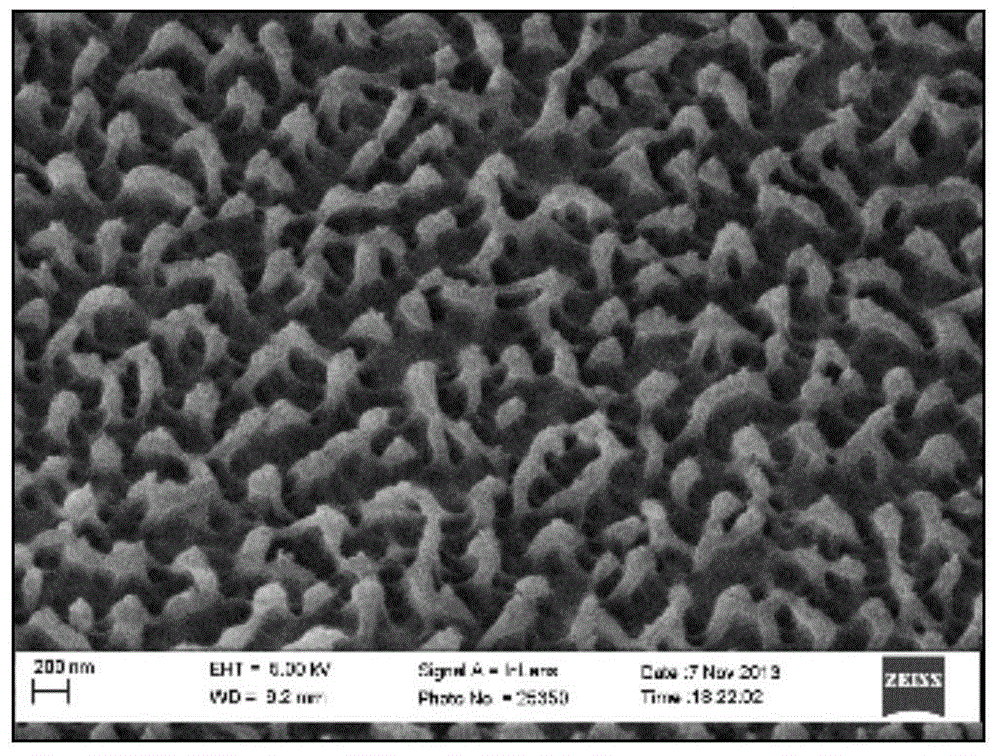

[0039] Introduce the structure of the generator in this embodiment in detail. see figure 1 , the first friction layer and the second friction layer adopt the surface-modified polyethylene terephthalate (PET) film material of nano-array, and its thickness is 25-50 micrometers, and in the polyethylene terephthalate material The other side is plated with an indium tin oxide (ITO) film as the electrode layer 101 . The base base of the nano-friction wind energy generator with the thickness of 500-1000 microns of polymer PMMA as the grass structure. Two elastic PET-ITO nanowire films are set opposite to each other;

[0040] In this embodiment, the material selection of each part of the generator is the same as that in the first embodiment, and will not be repeated here. The working principle of the generator when it is subjected to external vibration is also the same as that in the first embodiment.

Embodiment 3

[0042] The conductive material is separated from the insulator or semiconductor material after contact or friction, and charge transfer can occur on the surface of the two. In this embodiment, conductive gold, aluminum, etc. are used to replace the conductive material in the second embodiment, so as to further enhance the performance of the grass-structured nano-friction wind energy generator.

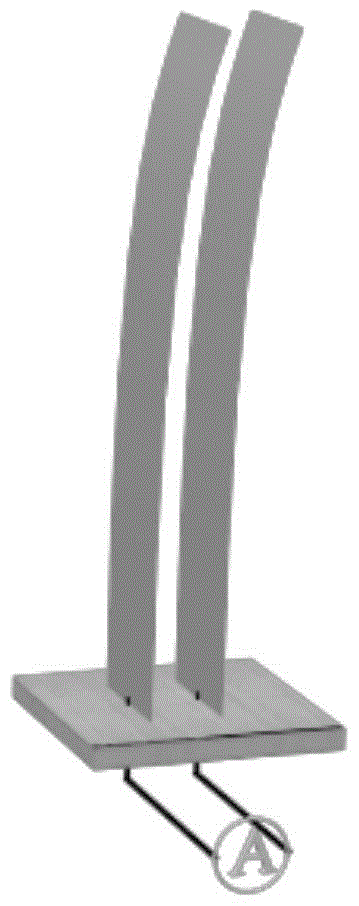

[0043] Combine below image 3 , Figure 4 and Figure 5 , specifically introduce the structure of the generator in this embodiment.

[0044] see Figure 4 , a three-dimensional diagram of a nano-friction wind energy generator with a grass structure with a number of ITO-PET film sheets n=2 and a nano-generator unit number of 1. see Figure 5 , a three-dimensional diagram of a nano-friction wind energy generator with a grass structure with a number of ITO-PET film sheets n=3 and a nano-generator unit number of 2. see Figure 4 , 4 The three-dimensional diagram of the nano-friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com