A preparation method of flexible nanoporous nickel/nickel oxide composite electrode sheet

A nanoporous nickel and composite electrode technology, applied in the field of new material technology and new energy, can solve the problem of poor mechanical properties of Ni-Zr precursor amorphous alloy thin strips, insufficient advantages in the application of flexible wearable electronic products, and reduced flexibility and other problems, to achieve the effect of short cycle time, low equipment cost and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

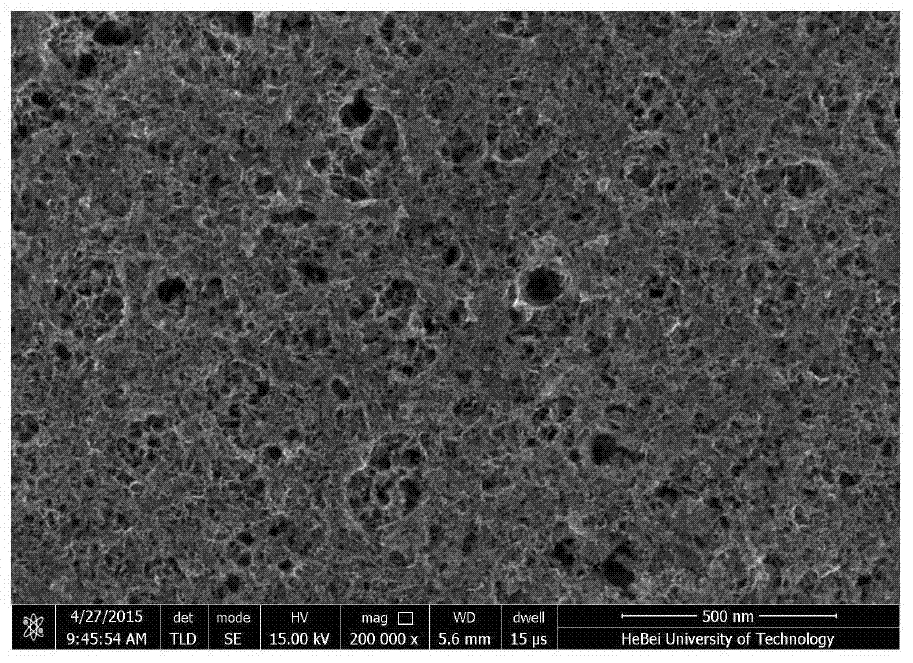

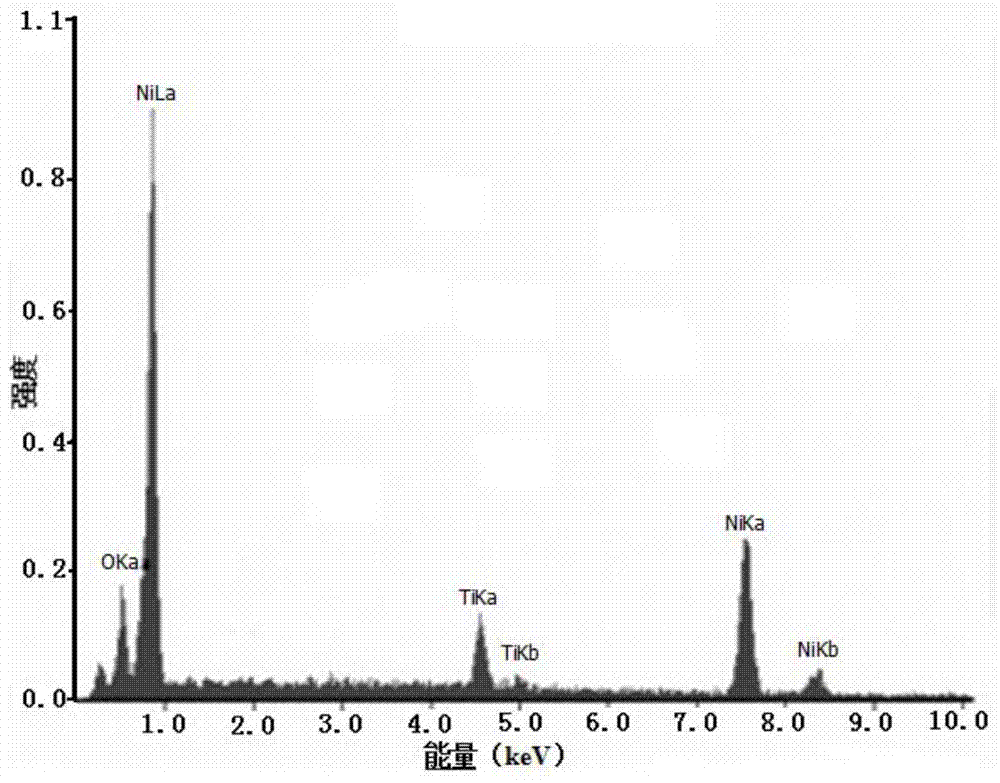

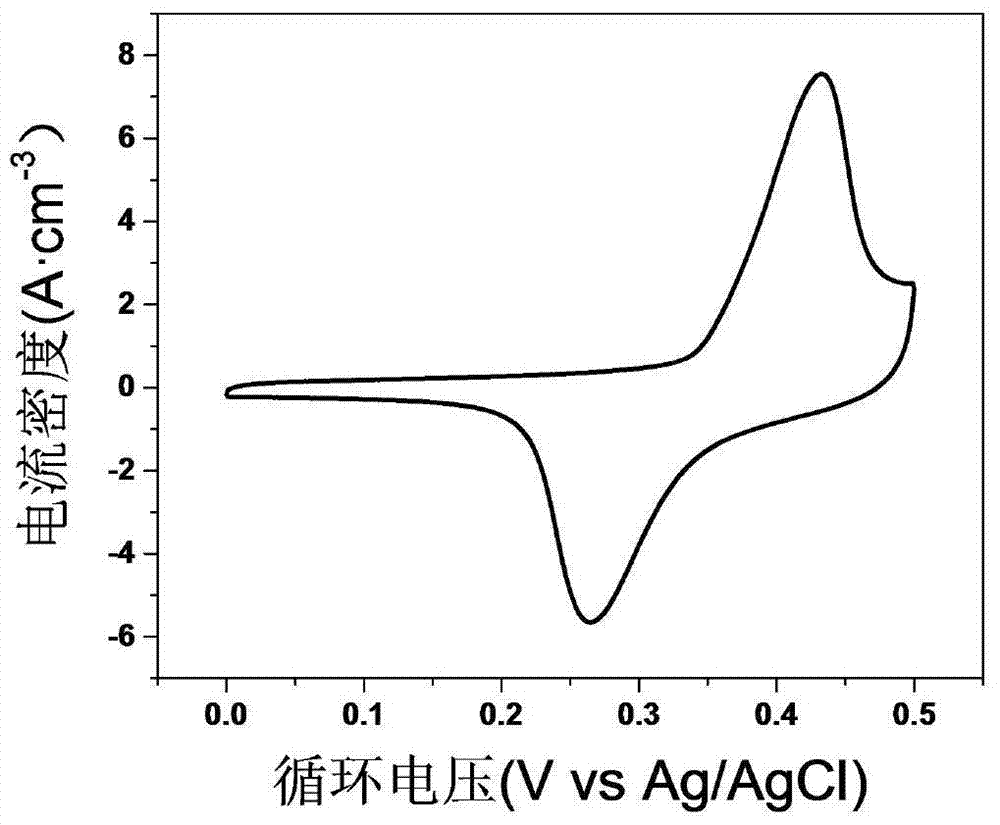

Embodiment 1

[0035] Select the alloy composition as Ni 40 Ti 60 , calculate its mass percent according to the atomic percent of element in the target alloy: Ni is 44.97%, Ti is 55.03%, takes by weighing the pure nickel (granular metal) 8.994g of purity 99.9wt% and the pure titanium of purity 99.9wt% ( Rod metal) 11.006g, mixed to obtain 20g of master alloy raw material. Then place the proportioned master alloy raw material in a vacuum electric arc melting furnace, and place 20 g of pure titanium with a purity of 99.9 wt% in the vacuum electric arc furnace independently without contacting the master alloy raw material, and melt it as an oxygen-scavenging material. The melting conditions are: the vacuum degree of the furnace chamber reaches 9.0×10 -4 Pa filled with argon to positive pressure; melting current 120 ~ 160A. Under the protection of argon, repeat the smelting of the master alloy 4 times, about 60 seconds each time, to ensure the uniformity of the alloy structure; after the smel...

Embodiment 2

[0044] Select the alloy composition as Ni 42 Ti 58 , calculate its mass percent according to the atomic percent of the element in the target alloy: Ni is 47.02%, Ti is 52.98%, takes by weighing the pure nickel (granular metal) 9.405g that purity is 99.9wt% and the pure titanium of 99.9%wt% ( Rod-shaped metal) 10.595 g were mixed to obtain 20 g of master alloy raw materials. Then place the proportioned master alloy raw material in a vacuum electric arc melting furnace, and place 20 g of pure titanium with a purity of 99.9 wt% in the vacuum electric arc furnace independently without contacting the master alloy raw material, and melt it as an oxygen-scavenging material. The melting conditions are: the vacuum degree of the furnace chamber reaches 9.0×10 -4 After Pa, rush into argon to positive pressure; the melting current is 120-160A. Under the protection of argon, the master alloy was repeatedly smelted 4 times, each time for about 60 seconds, to ensure the uniformity of the ...

Embodiment 3

[0051] Select the alloy composition as Ni 38 Ti 62 , calculate its mass percent according to the atomic percent of element in the target alloy: Ni is 42.90%, Ti is 57.10%, takes by weighing the pure nickel (granular metal) 8.580g that purity is 99.9wt% and the pure titanium of 99.9%wt% ( Rod-shaped metal) 11.420 g were mixed to obtain 20 g of master alloy raw materials. Then place the proportioned master alloy raw material in a vacuum electric arc melting furnace, and place 20 g of pure titanium with a purity of 99.9 wt% in the vacuum electric arc furnace independently without contacting the master alloy raw material, and melt it as an oxygen-scavenging material. The melting conditions are: the vacuum degree of the furnace chamber reaches 9.0×10 -4 After Pa, rush into argon to positive pressure; the melting current is 120-160A. Under the protection of argon, the master alloy was repeatedly smelted 4 times, each time for about 60 seconds, to ensure the uniformity of the allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com