Method for analyzing convection heat dissipation performance of both sides of rectangular heat dissipation plate with eccentric heat source

A technology of heat dissipation performance and analytical method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to obtain accurate temperature values and underestimation of local maximum temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

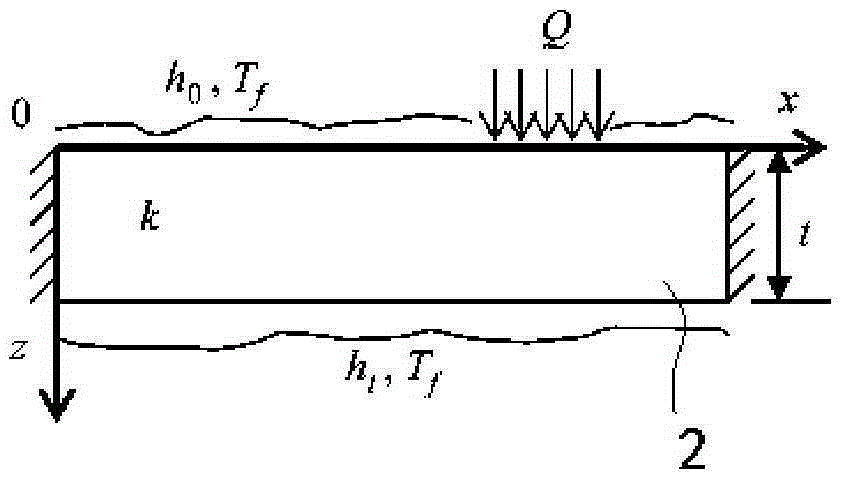

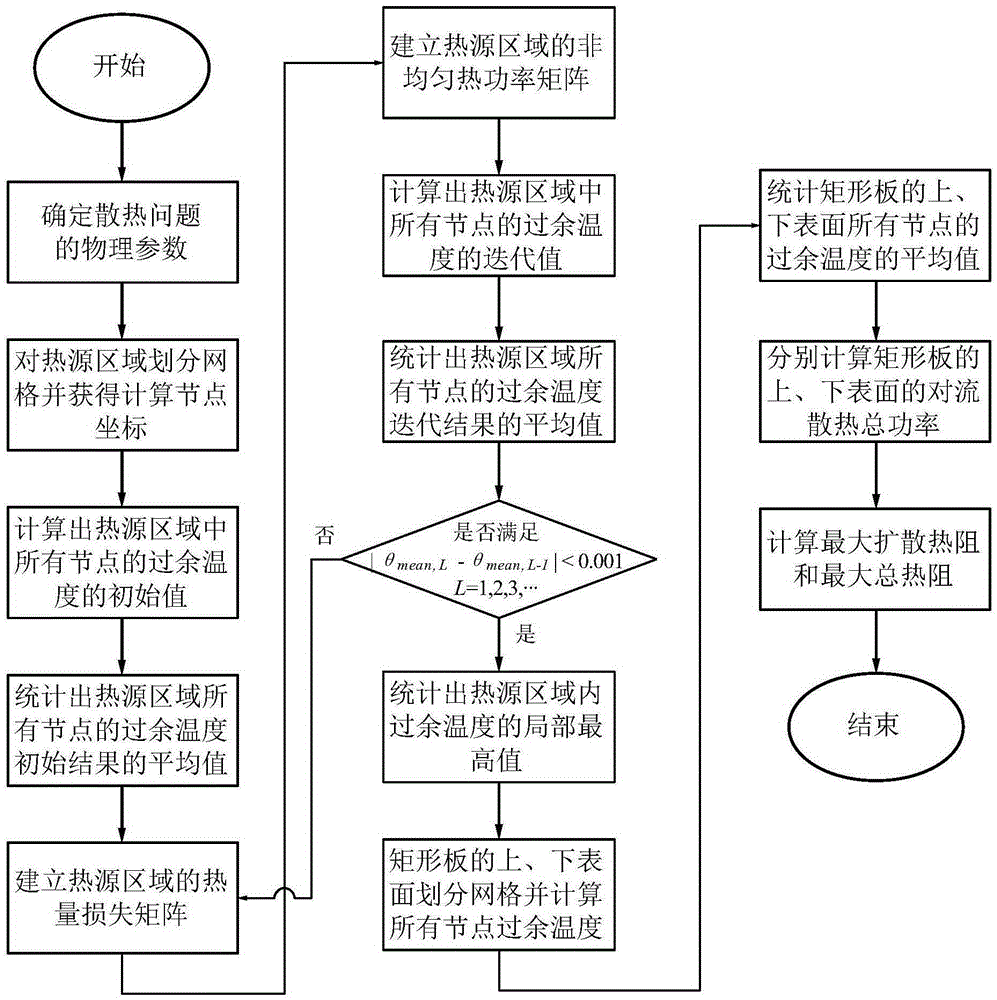

[0074] Referring to Figures 1-2, the analytical method for the double convective heat dissipation performance of a rectangular heat sink with an eccentric heat source includes the following steps:

[0075] (1) Determine physical parameters for heat dissipation problems or performance analysis

[0076] Before analyzing and calculating the performance of double-sided convective heat dissipation of a rectangular heat sink with eccentric heat source, the physical parameters that need to be determined first are: the area A of the two-dimensional heat source 1 s =c×d and its uniform heating power Q; the upper and lower surface area A of the rectangular cooling plate 2 b = a × b and its thickness t; the thermal conductivity k of the rectangular cooling plate; the central coordinates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com