Method and monitoring system for detecting and separating micro fault in industrial process

A technology of industrial process and separation method, which is applied in the field of detection and separation method and monitoring system of minor faults in industrial process, can solve the problems of high fault omission rate, wrong location of fault variables, poor detection performance of minor faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

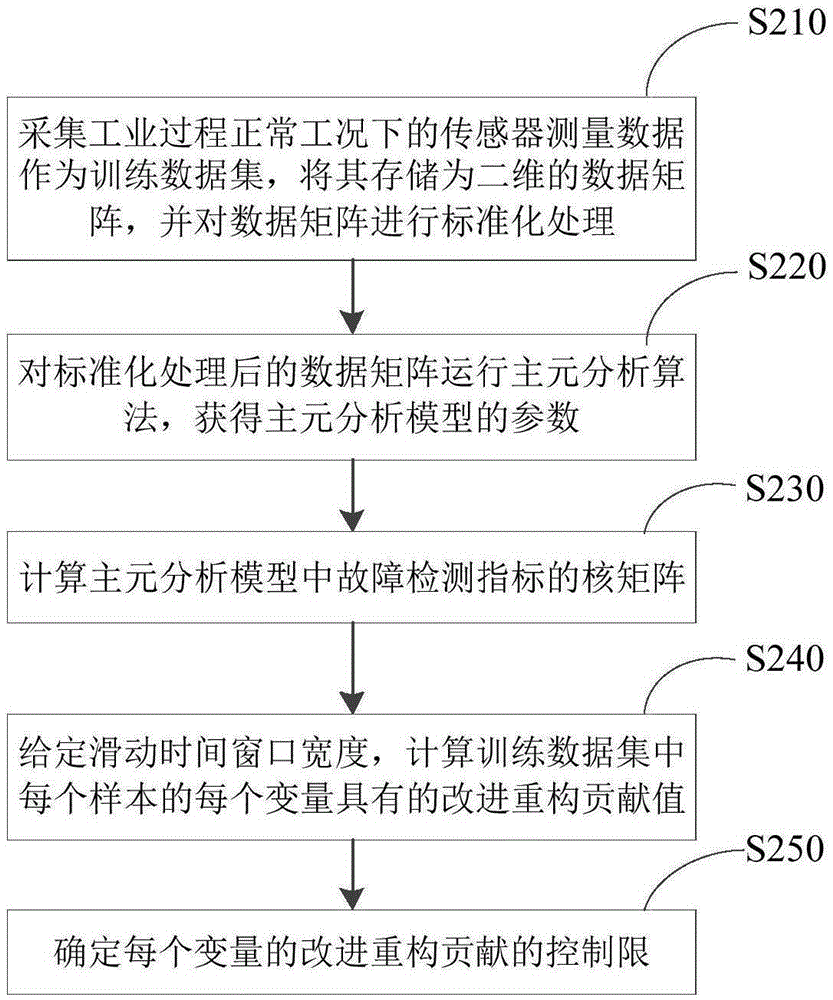

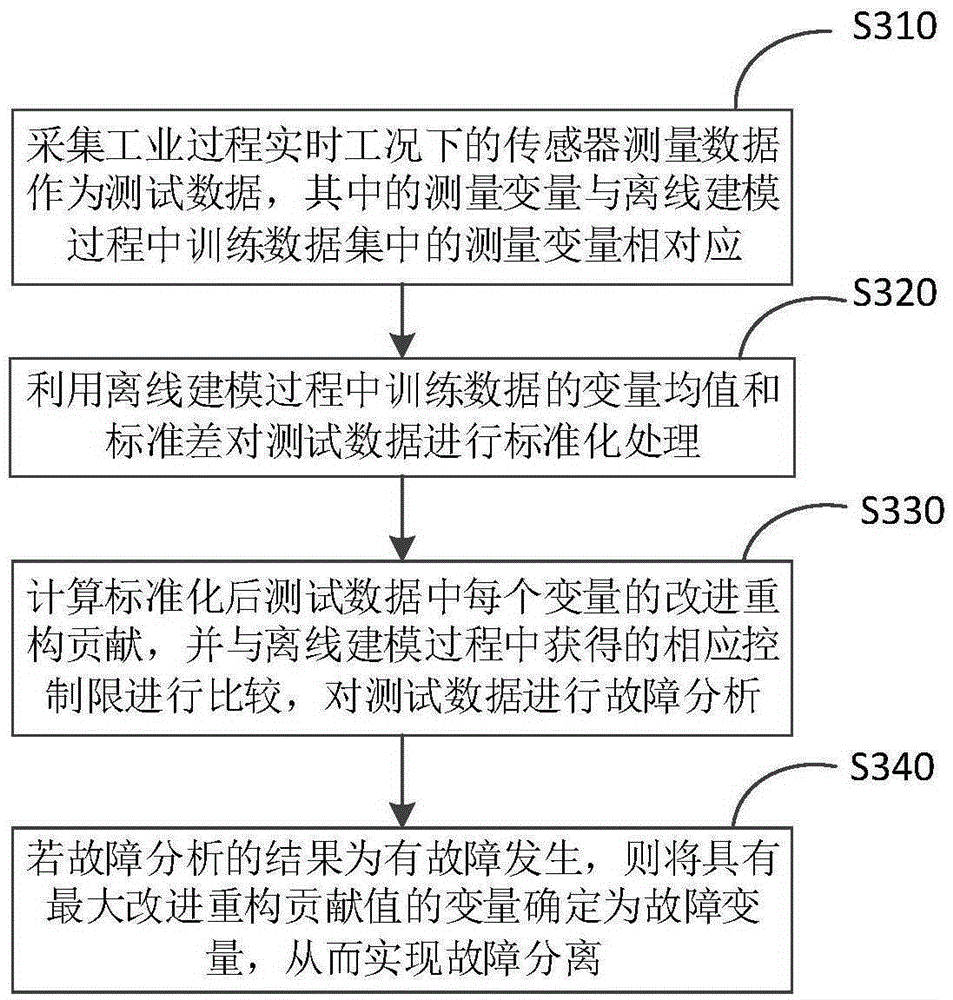

[0055] The basic idea of the present invention is: based on the traditional principal component analysis method (principal component analysis, PCA) and reconstruction-based contribution graph method (reconstruction-based contribution, RBC), with the help of sliding time window technology, a new statistical index is proposed to realize the industrial process miniaturization. Detection and isolation of faults.

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

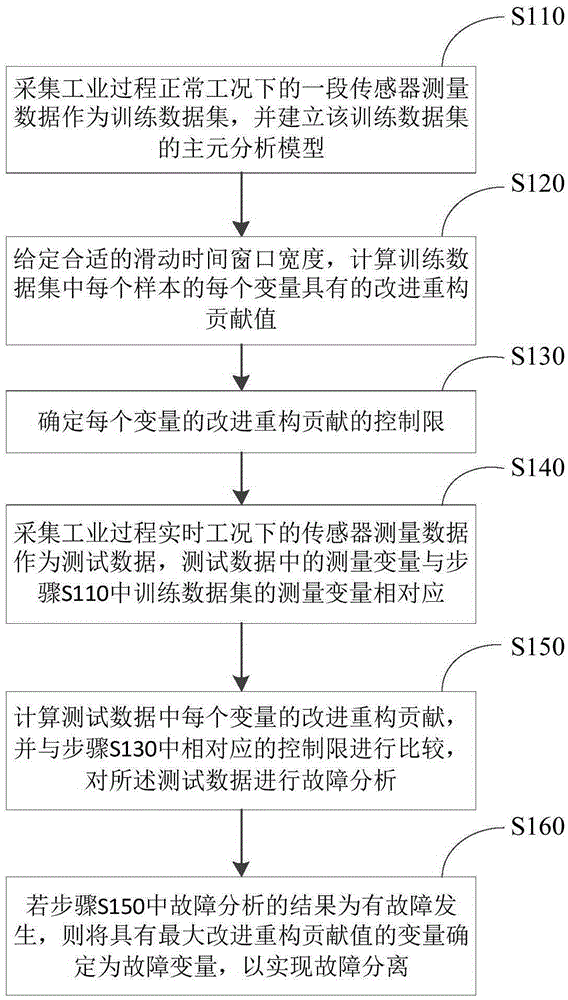

[0057] combine figure 1 As shown, a method for detection and separation of micro-faults in industrial processes, including the following steps:

[0058] Step S110 collects a section of sensor measurement data under normal working conditions of the industrial process as a training data set, and establishes a principal component analysis model of the training data set;

[0059] Step S120 gives an appropriate sliding time window width, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com