Method for measuring and representing microcosmic interface phases of asphalt concrete

A technology of asphalt concrete and interfacial phase, which is applied in the direction of testing material hardness and applying stable tension/pressure to test material strength, etc. It can solve the problems affecting the collection and calculation of load-displacement curves, test failures, and unreliable tests for the mechanical properties of interface phases Program and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] A method for testing and characterizing asphalt concrete microscopic interfacial phases, comprising the following steps:

[0035] (1) Prepare the sample first

[0036] The nano-indentation test requires the surface of the sample to be flat and smooth, so as to reduce the variation of the data caused by the unevenness in the Z-axis direction, reduce the error, and ensure the reliability of the data. Therefore, the sample must be finely ground, but the asphalt concrete grinding process is easy It is peeled off and deformed, and it is not easy to fix. Therefore, in this test method, it is fixed in epoxy resin. The specific operation steps are as follows:

[0037] 1) Cut the asphalt concrete specimen into small pieces with a size of about 1.5 cm;

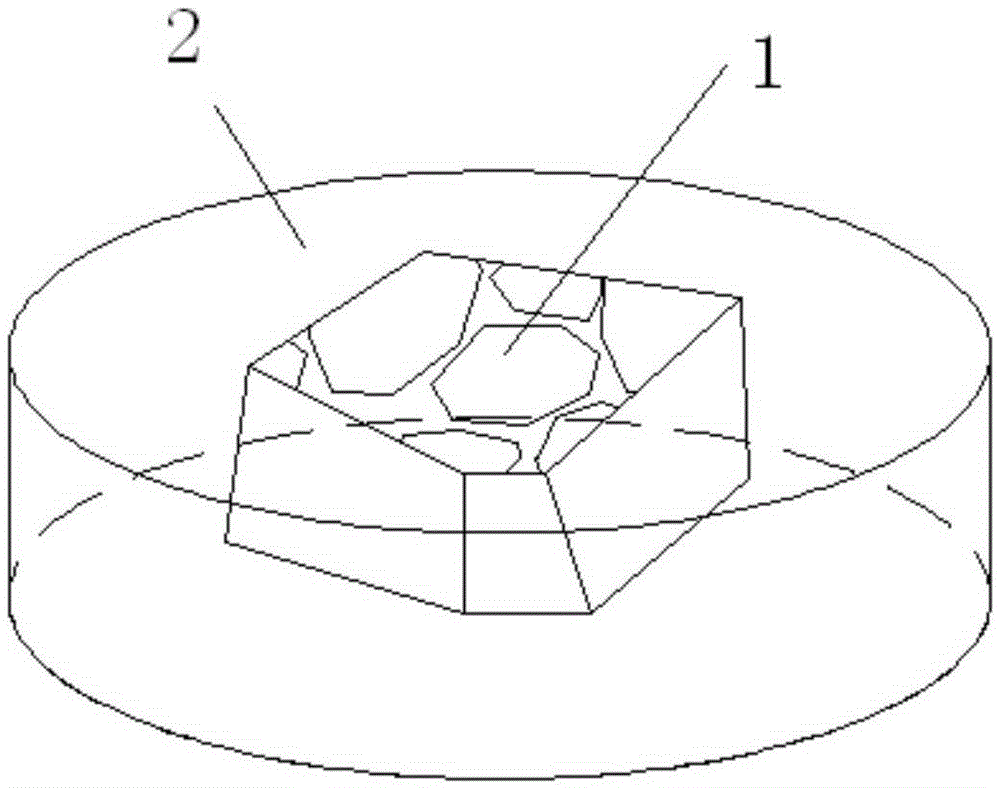

[0038] 2) if figure 1 As shown, mix epoxy resin AB glue 2 in proportion (volume ratio 2.5:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com